Heat-insulating plastic pipe

A technology for plastic pipes and pipes, applied in the direction of heat preservation, pipe protection through heat insulation, pipe protection, etc., can solve the problems of easy bending, no heat preservation, poor load-bearing capacity, etc., and achieve improved longitudinal strength, good wear resistance, and good Anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

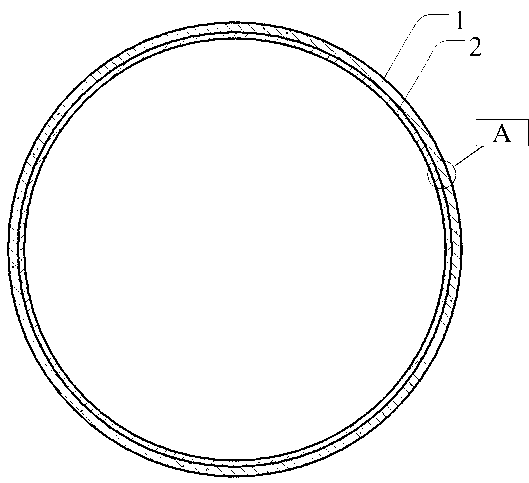

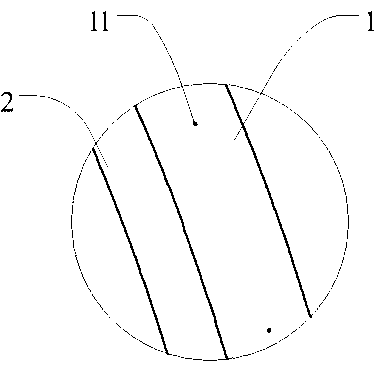

[0017] A thermal insulation plastic pipe, the inner layer of the pipe wall is a fiber winding layer, the outer layer is a foam plastic layer, and the winding angle of the fiber winding inner layer is 75° O , thickness 2mm, carbon fiber content 60%, resin 30%, the balance is quartz sand; the thickness of the foam plastic layer is 8mm, and the diameter of the steel wire embedded inside is 1mm.

Embodiment 2

[0019] A thermal insulation plastic pipe, the inner layer of the pipe wall is a fiber winding layer, the outer layer is a foam plastic layer, and the winding angle of the fiber winding inner layer is 79° O , thickness 2mm, glass fiber content 50%, resin 25%, the balance is quartz sand; the thickness of the foam plastic layer is 10mm, and the diameter of the embedded steel wire is 1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com