Electro-chemical corrosion simulator with in-situ loading

A simulation device, electrochemical technology, applied in the field of materials, can solve problems such as corrosion failure, material performance impact, etc., to achieve the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

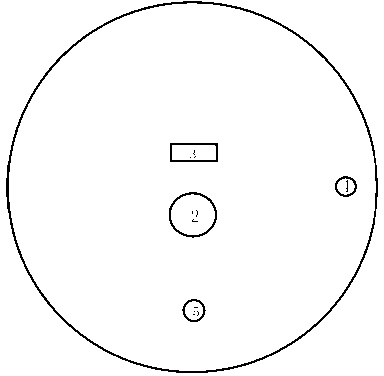

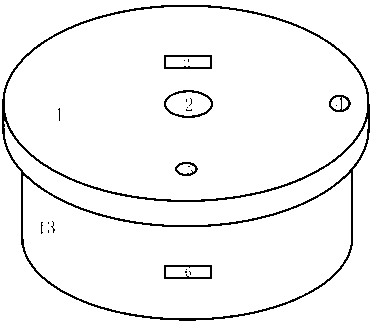

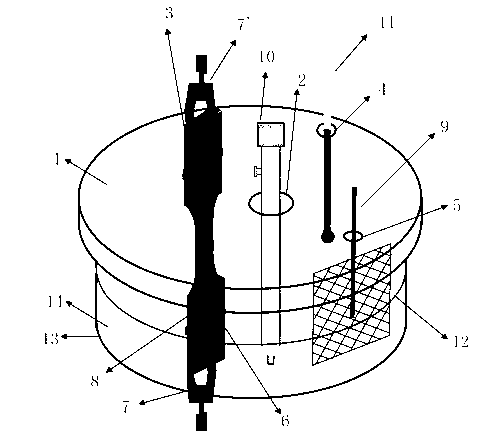

[0025] The present invention relates to an electrochemical corrosion simulation device loaded in situ, which mainly consists of an electrolytic cell 13, an upper cover 1 of the electrolytic cell, a working electrode 8, a reference electrode 10, an auxiliary electrode 9 and clamps 7, 7', Thermometer 11 and electrolytic solution 14 are made up, and wherein, the fixture 7 and 7 ' of tensile testing machine are connected with tensile testing machine, and working electrode 8 passes through the lower hole 6 of the installation sample along electrolytic cell 13, seals and fixes, and electrolytic cell Electrolytic solution 14 is arranged in 13, keep the upper hole 3 of installing sample on the electrolytic cell loam cake 1 and the lower hole 6 of the installing sample of electrolytic cell 13 parallel, insert the aperture 2 of reference electrode in electrolytic cell loam cake 1, insert auxiliary electrode The reference electrode 10, the auxiliary electrode 9 and the thermometer 11 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com