Air cooled electric automobile battery thermal-management device containing phase change material

A battery thermal management and air cooling technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of fast battery aging, battery pack temperature rise, battery pack failure, etc., to achieve good interlayer sealing, The effect of good thermal conductivity and strong heat storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

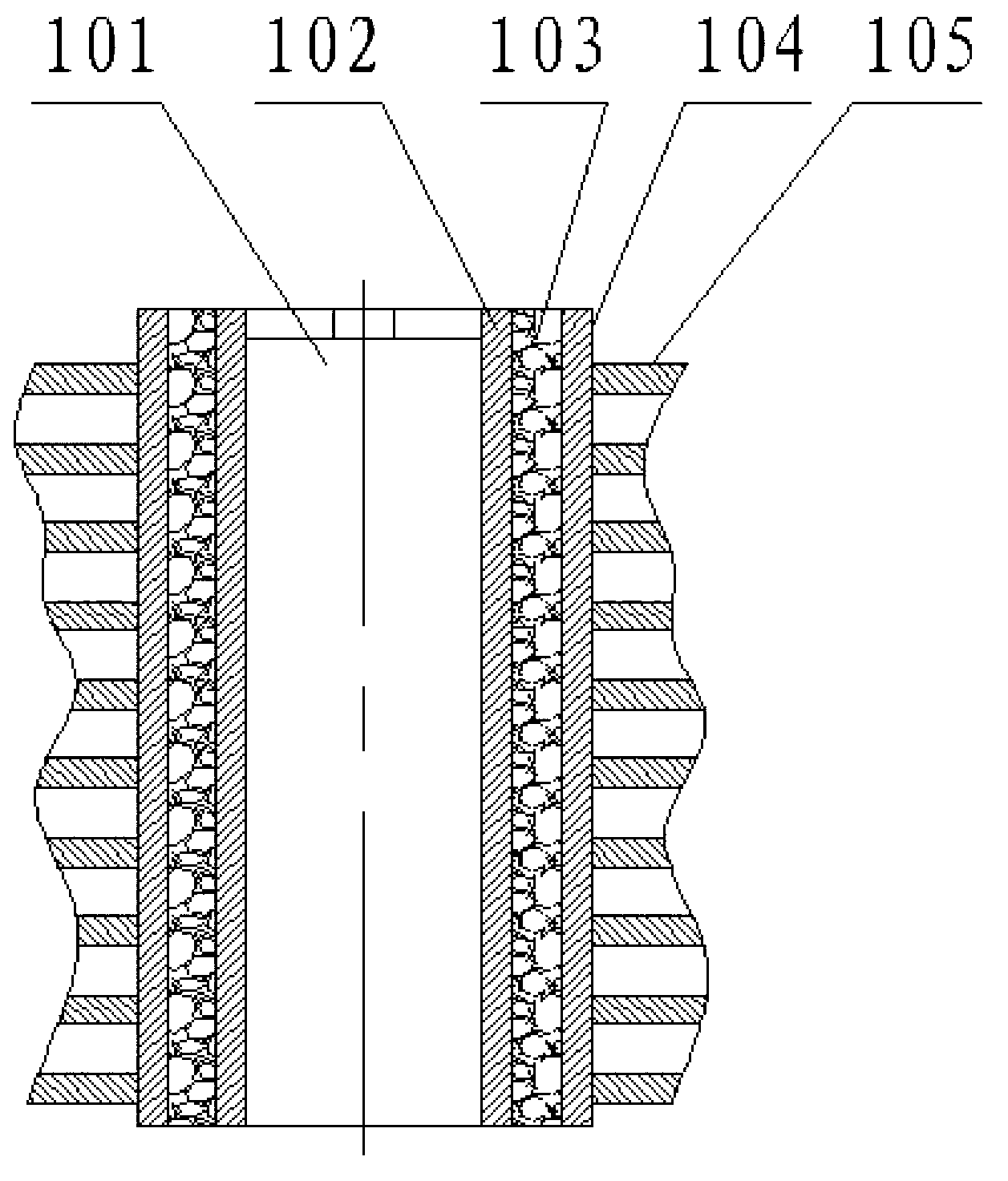

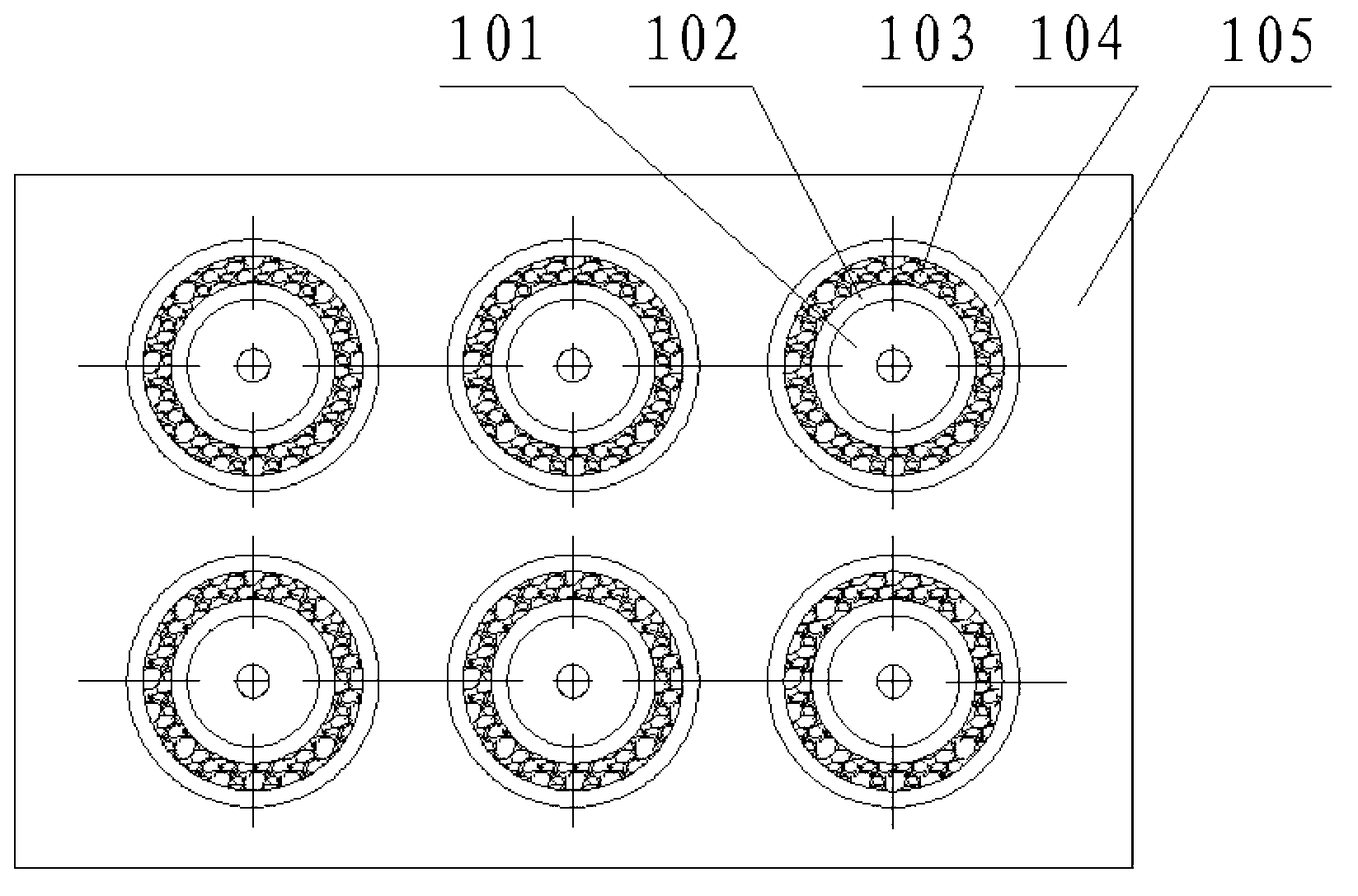

[0024] Such as figure 1 As shown, an air-cooled electric vehicle battery thermal management device containing phase change materials includes a battery box, and a plurality of interconnected batteries 101 are arranged in the battery box, and the outer wall of the battery is covered with an interlayer, and the interlayer The inner shell 102 is bonded to the outer wall of the battery 101 to reduce thermal contact resistance, and a porous medium is filled between the inner shell 102 of the interlayer and the outer shell 104 of the interlayer, and the phase change material 103 is filled in the pores of the porous medium. Heat dissipation fins 105 are arranged on the sandwich shell.

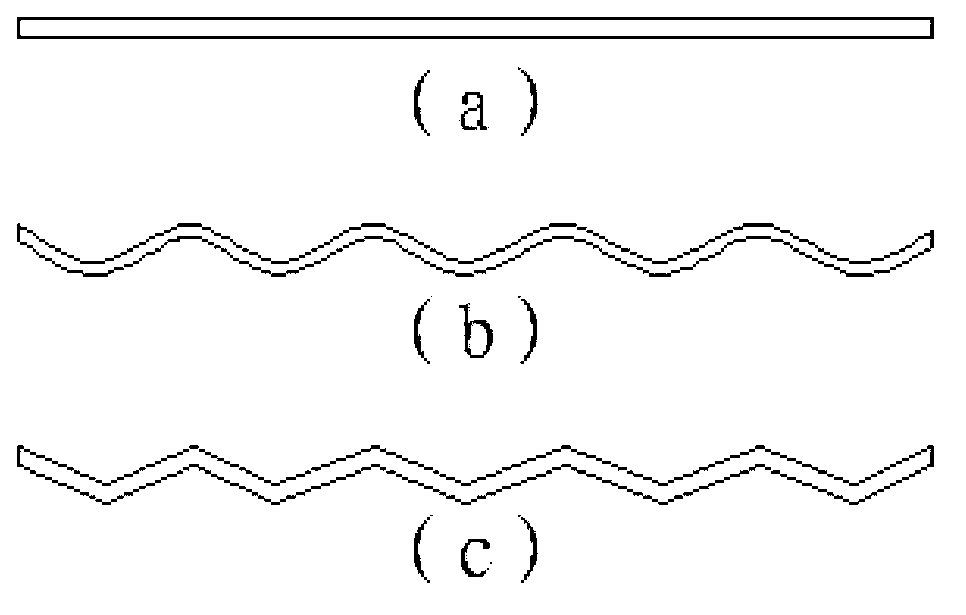

[0025] Such as image 3 As shown in (a), (b) and (c), the heat dissipation fins 105 are one of flat plate type, corrugated plate type or triangular corrugated plate type to enhance the heat dissipation effect.

[0026] The batteries 101 in the battery box can be arranged in sequence, staggered or in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com