A kind of preparation method of biocathode based on silicon rubber

A biocathode and silicone rubber technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of power supply, energy loss, and weak current that cannot be used as implantable medical equipment, and achieve direct electrochemistry without cracks , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The first step: modification method of carbon nanotubes

[0026] Put 5 g of multi-walled carbon nanotubes (inner diameter 2-5 nm, outer diameter 40-50 nm) into a round-bottomed flask filled with 200 ml of concentrated nitric acid with a concentration of 65% to 68%, and sonicate for 30 min at 20°C. Then connect the condensing device, heat the mixture of multi-walled carbon nanotubes and concentrated nitric acid to 100°C, and react at 100°C for 5h. After the reaction, the mixture of multi-walled carbon nanotubes and concentrated nitric acid was centrifuged and washed with deionized water until neutral. Finally, the multi-walled carbon nanotubes obtained after the treatment were placed in a vacuum oven and dried at 40°C for 24 h.

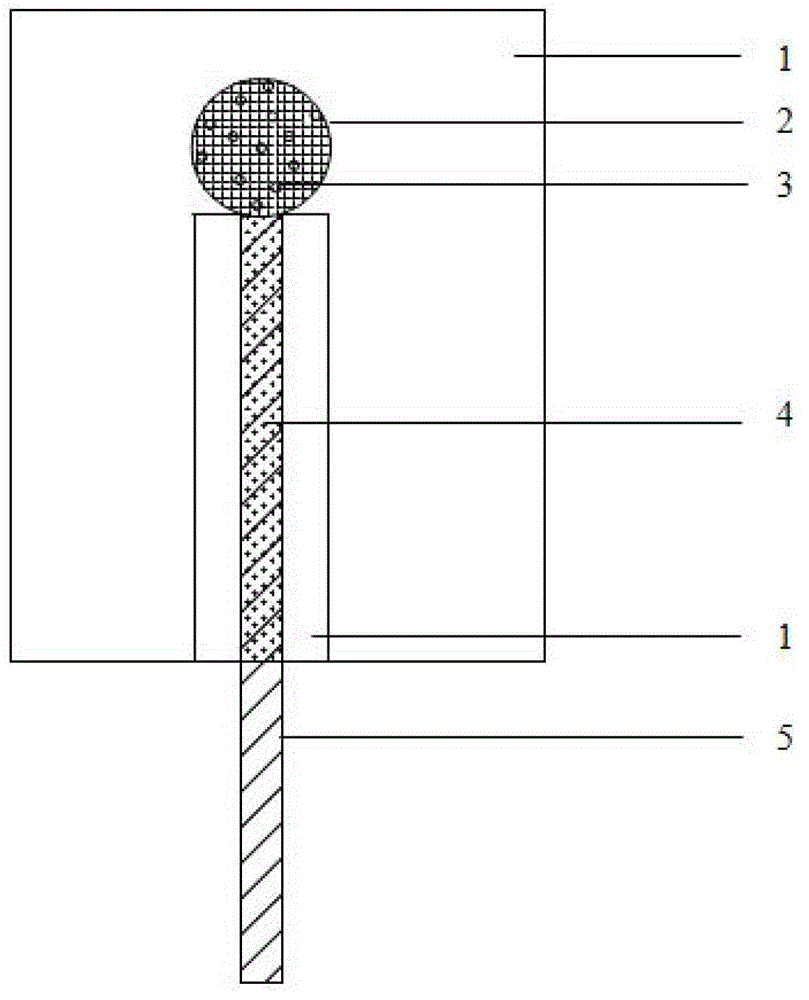

[0027] The second step: preparation method and characterization of multi-walled carbon nanotube-chitosan composite cathode

[0028] The configuration of the acetic acid solution of chitosan: join 1g chitosan in 100ml dilute acetic acid (1%, v / ...

Embodiment 2

[0039] The first step: modification method of carbon nanotubes

[0040] Same as the operation process of the first step in embodiment 1.

[0041] The second step: preparation method and characterization of multi-walled carbon nanotube-cellulose composite cathode

[0042] Preparation of the ionic liquid solution of cellulose: Dissolve the cellulose in the ionic liquid (1-ethyl-3-methylimidazolium acetate) (cellulose content 5%wt) under ultrasonic and heating conditions, and set aside.

[0043] Weigh 1.0 g of multi-walled carbon nanotubes obtained in step 1 and 200 g of cellulose ionic liquid in an agate mortar, and grind the mixture in a dry environment until the mixture becomes a slurry to obtain an enzyme-type bioelectrode material, which is sealed and stored. Wherein, the mass ratio of multi-walled carbon nanotubes and cellulose is 1:10.

[0044] The above-mentioned enzyme-type bioelectrode material is coated on the surface of silicone rubber through a circular mold to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com