Method for rapidly forming carbon-loaded doped anti-spinel ferroferric oxide film capable of realizing alkaline hydrogen evolution

A technology of ferric oxide film and reverse spinel, which is applied in the direction of electrolytic components, electrodes, electrolytic process, etc., can solve the problems of expensive and limited platinum-based metals, and achieve good electrical conductivity, improved supply, and large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

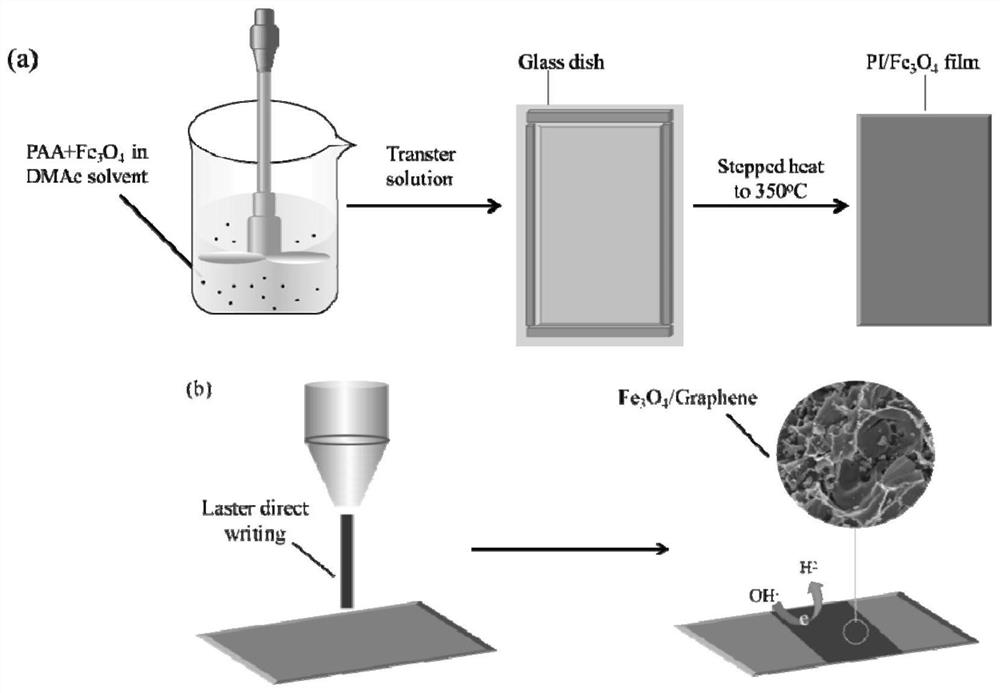

[0032] A certain amount of PAA resin will be weighed and added to a 250mL three-necked flask equipped with an appropriate amount of DMAc solvent. 3 o 4 and melamine-coated ammonium polyphosphate, and mechanically stirred to obtain a PAA composite resin with a solid content of about 15%. Pour the PAA composite resin on a dry glass plate, and carry out a stepwise temperature rise. The stepwise temperature rise program is 50°C for 1h, 100°C for 1h, and 250°C for 2h. Thermal imidization reaction occurs to obtain PI / Fe 3 o 4 Composite film.

[0033] Laser ablation of the composite film: before laser ablation of the composite film, the PI / Fe 3 o 4 The surface of the composite film was cleaned, and then dried in a drying oven at 50°C for 8 hours. Then, the PI / Fe 3 o 4 The composite film is flatly fixed on the operating table, and the focus of the fiber laser and the PI / Fe 3 o 4 The surface of the composite film is overlapped, and the laser processing parameters are set. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com