Double-sided silk-screen printing electrode based on flexible plastic substrate and preparation method of double-sided silk-screen printing electrode

A technology of screen-printed electrodes and flexible plastics, applied in medical science, blood characterization devices, sensors, etc., can solve problems such as low precision, complicated processing technology, and poor patient experience, so as to improve precision, optimize electrode structure, and reduce discomfort Sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

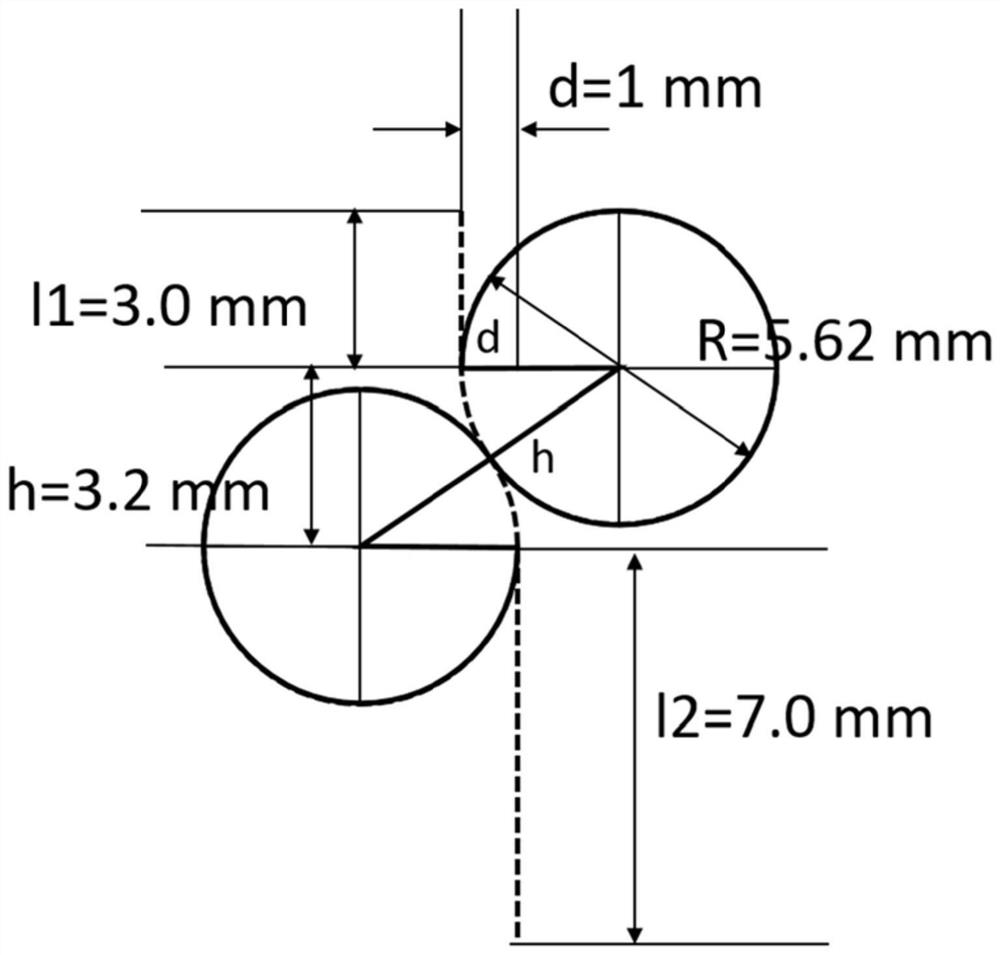

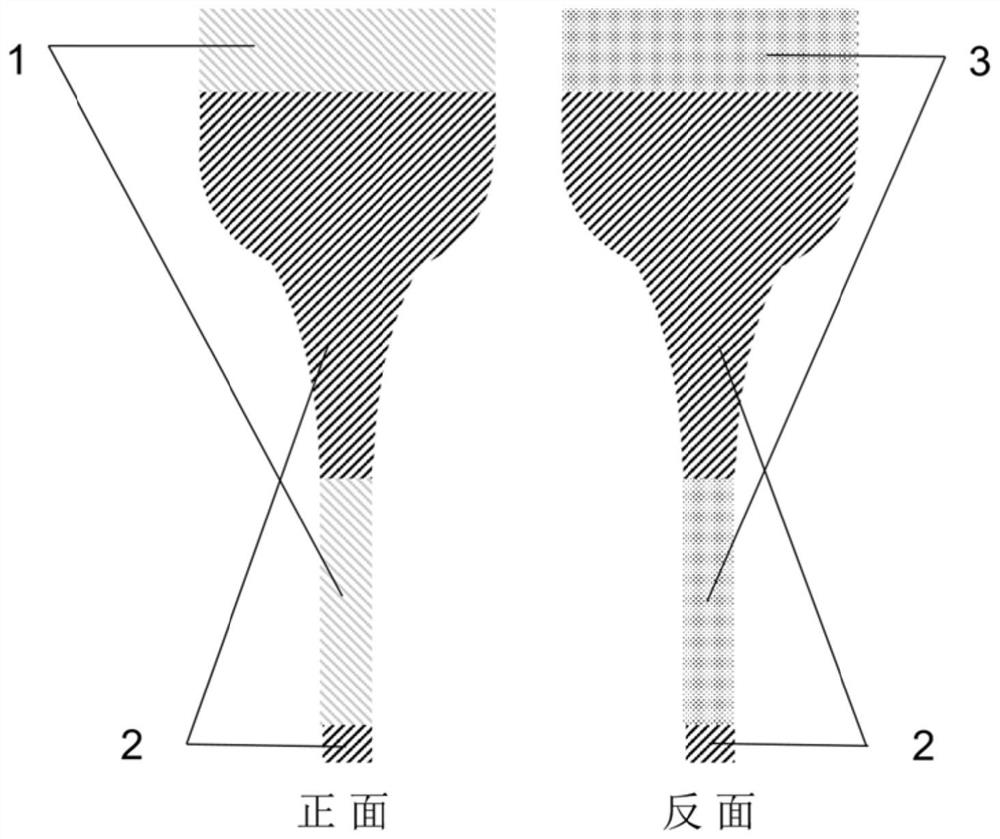

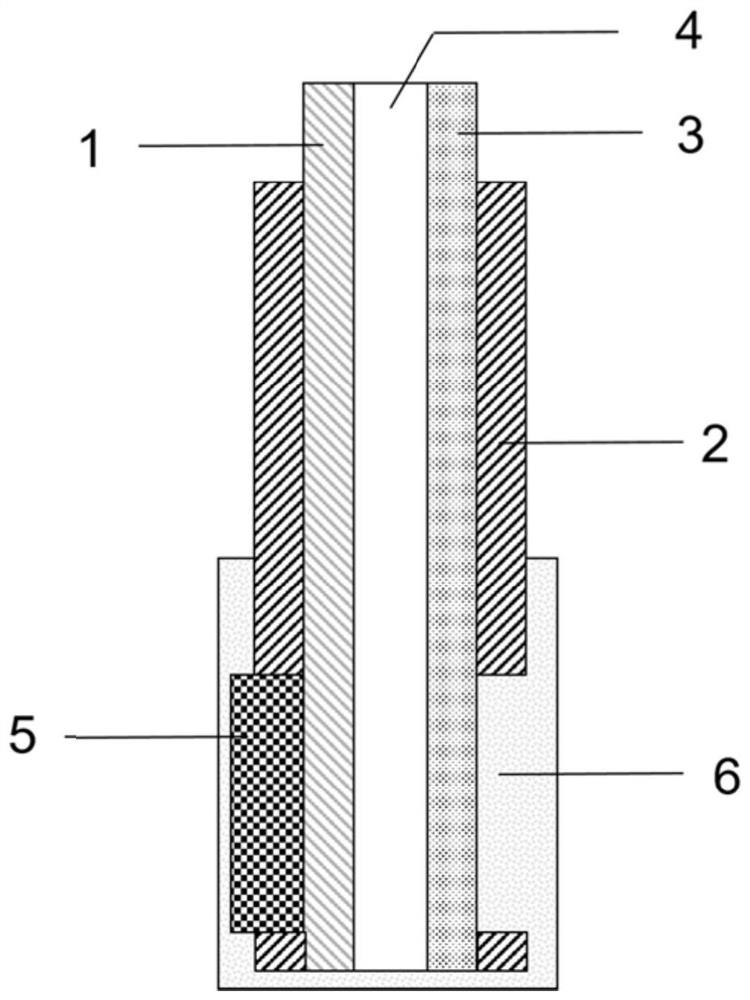

[0034] Such as figure 2 and Figure 4 As shown, this embodiment provides a double-sided screen-printed electrode based on a flexible plastic substrate, including a substrate 4 , a working electrode 1 and a counter electrode 3 . A working electrode is printed on one side of the substrate, and a counter electrode is printed on the other side. The working electrode 1 and the counter electrode 3 are respectively located at the same position on the front and back sides of the substrate 4, and the vertical projections of the working electrode 1 and the counter electrode 3 on the center plane of the substrate 4 coincide, that is to say, the working electrode 1 and the counter electrode 3 The position, shape and size are all the same, and the mirror surface is symmetrical with the substrate 4. In addition, the working electrode 1 and the counter electrode 3 are not connected to each other and are independent electrodes.

[0035] The substrate can be selected from a wide range of m...

Embodiment 2

[0043]This embodiment provides a method for preparing a double-sided screen-printed electrode based on a flexible plastic substrate. It should be noted that, in this embodiment, the screen printing machine used is a fully automatic screen printing machine produced by Dongguan Unikai Intelligent Machine Co., Ltd. In this embodiment, some steps are also combined with some functions of the screen printing machine, and the structure of other screen printing machines may be inconsistent with the structure provided in this embodiment, but it cannot affect the protection scope of the present invention. Similarly, in this embodiment, the automatic cutting machine used is a fully automatic edge patrol die-cutting machine produced by Shenzhen Jingyi Intelligent Technology Co., Ltd. In this embodiment, some steps are also combined with some functions of the cutting machine, and the structure of other cutting machines may be inconsistent with the structure provided in this embodiment, but...

Embodiment 3

[0064] This embodiment provides a method for preparing a double-sided screen-printed electrode based on a flexible plastic substrate. It should be noted that, in this embodiment, the screen printing machine used is a fully automatic screen printing machine produced by Dongguan Unikai Intelligent Machine Co., Ltd. In this embodiment, some steps are also combined with some functions of the screen printing machine, and the structure of other screen printing machines may be inconsistent with the structure provided in this embodiment, but it cannot affect the protection scope of the present invention. Similarly, in this embodiment, the automatic cutting machine used is a fully automatic edge patrol die-cutting machine produced by Shenzhen Jingyi Intelligent Technology Co., Ltd. In this embodiment, some steps are also combined with some functions of the cutting machine, and the structure of other cutting machines may be inconsistent with the structure provided in this embodiment, bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com