Continuous connecting pipe used for connecting aluminum alloy core all-aluminum conductor

A technology of core aluminum stranded wire and aluminum alloy, which is applied in the direction of connection and cable joint where permanent deformation plays a role, can solve the problems of complicated process and high cost, and achieve the effect of mature process, convenient operation and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

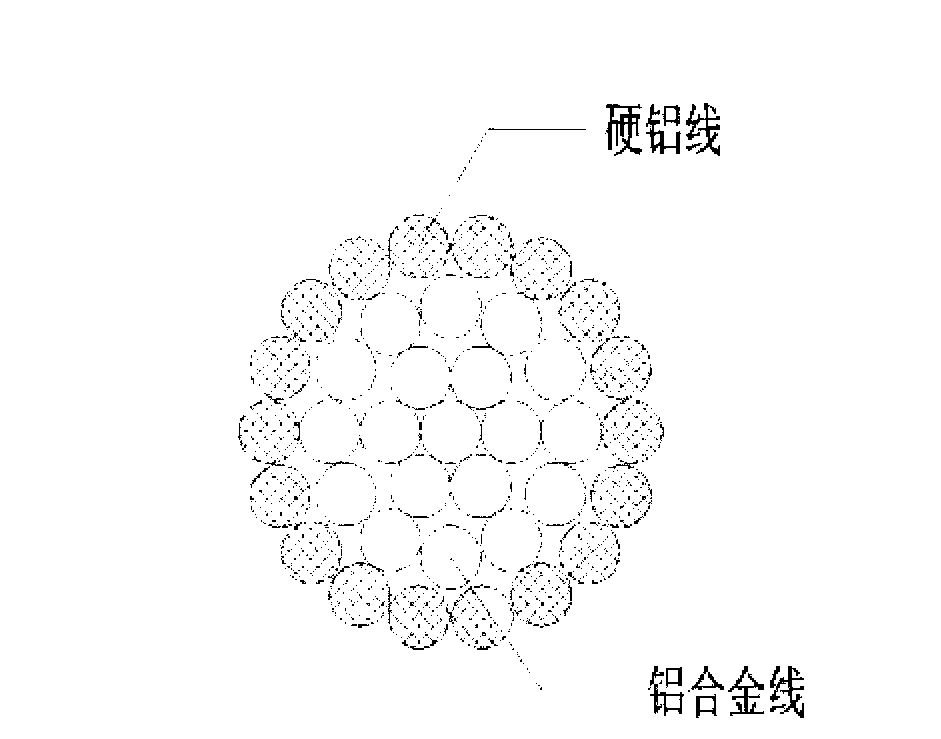

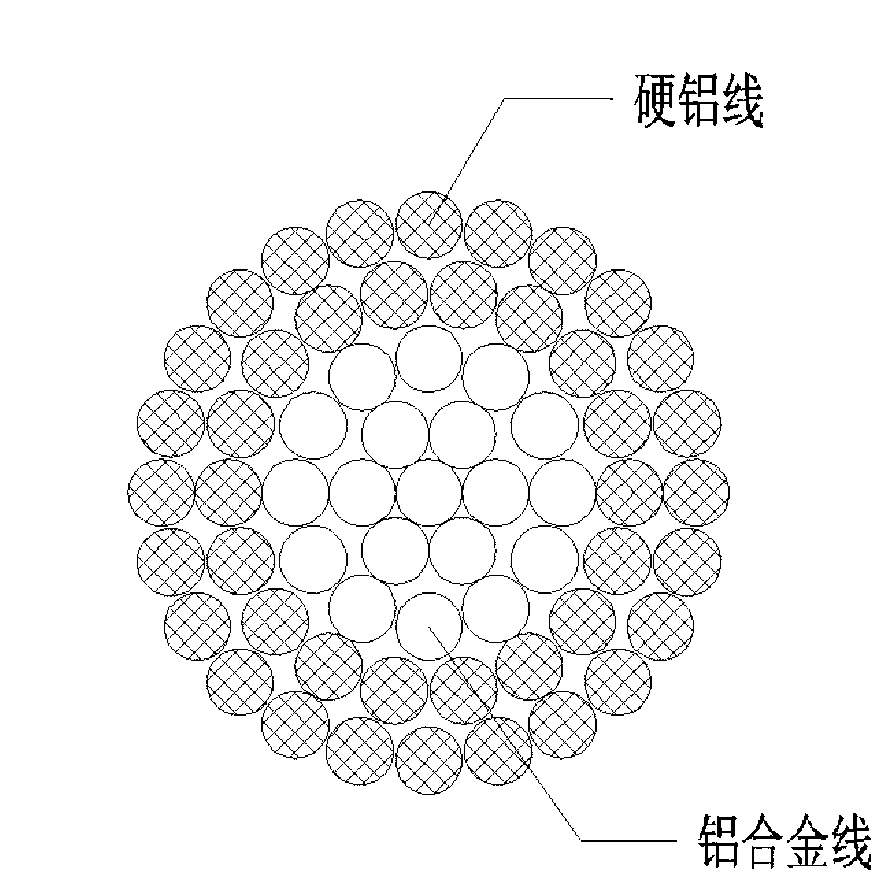

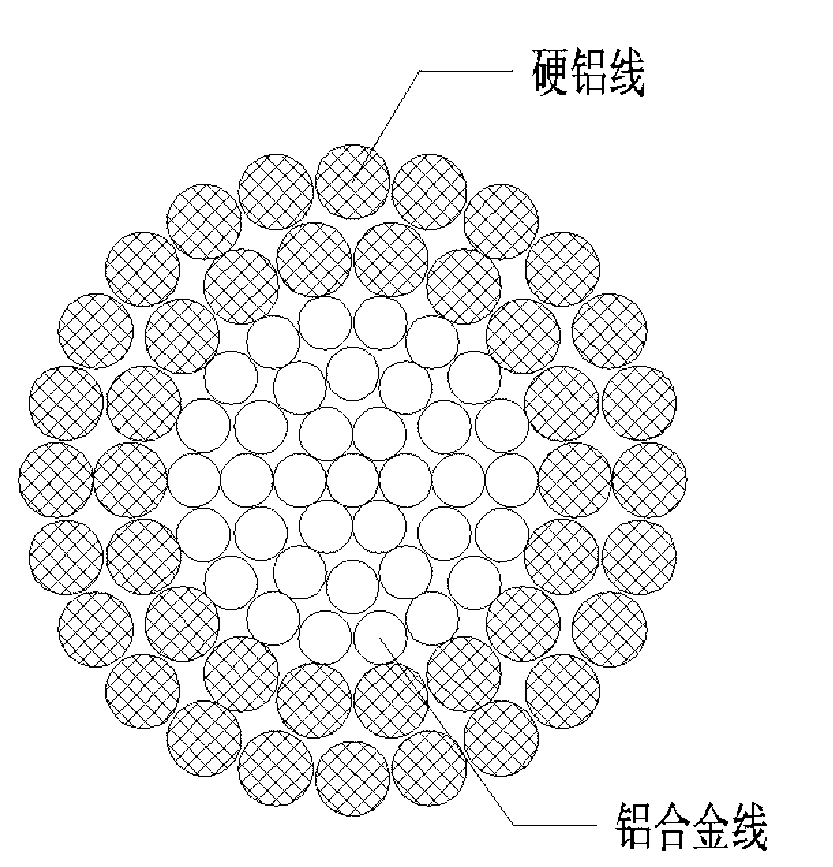

[0029] This embodiment takes the connecting pipe as an example, such as Figure 1 to Figure 5 As shown, the connecting pipe provided by the embodiment of the present invention includes: an aluminum alloy pipe 2 and an aluminum pipe 1; stranded wire4.

[0030] Aluminum alloy cored aluminum stranded wire: one or more aluminum alloy aluminum stranded wires are used as the aluminum alloy strengthening core, and multi-layer aluminum stranded wires are spirally wound on the aluminum alloy reinforced core, and each layer of aluminum stranded wire includes multiple single wires. The helical winding directions of every two adjacent layers of aluminum stranded wires are opposite.

[0031] The manufacturing method of the splicing pipe provided by the present invention is as follows: peel off a section of the outer wrapped aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com