Laminar flow type leaf multi-point material adding/perfuming unit

A blade and flow technology, which is applied in the field of tobacco leaf feeding/flavoring devices, can solve problems such as easy clustering of leaves, uneven feeding/flavoring of leaves, and failure to meet the requirements of cigarette production technology, and achieve convenient operation and maintenance. The effect of improving and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

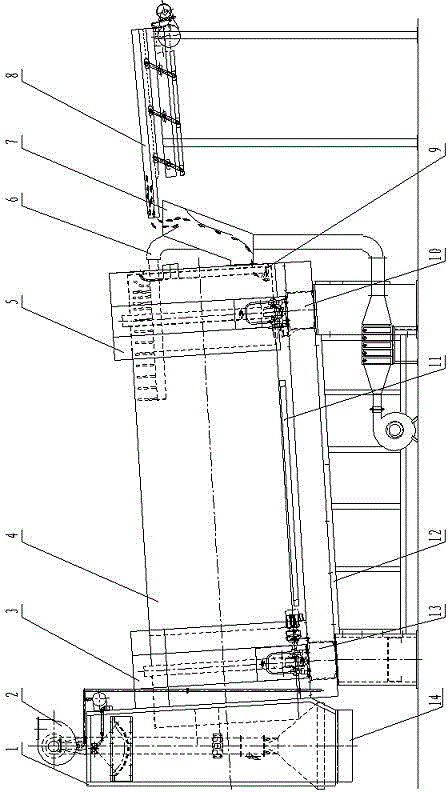

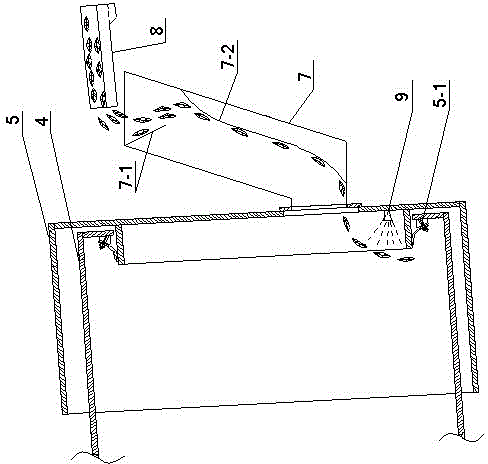

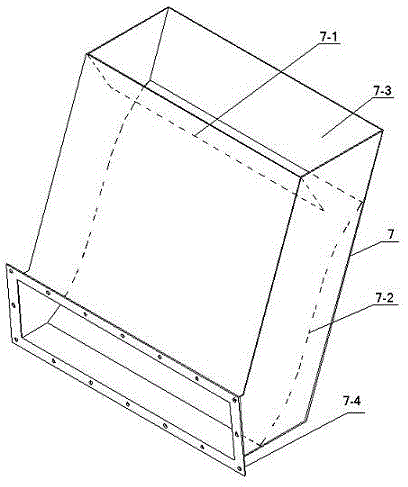

[0012] Referring to the accompanying drawings, 1 in the figure is a discharge cover, 2 is a moisture removal device, 3 is a rear cover, 4 is a cylinder, 5 is a front cover, and 5-1 is a dynamic seal installed between the front cover and the cylinder device, 6 is the air outlet pipe of the hot air purging device, 7 is the laminar flow uniform material device, 7-1 is the inlet guide plate, 7-2 is the guide slide plate, 7-3 is the feed port, 7 -4 is the mounting flange, 8 is the feeding vibrating conveyor, 9 is the nozzle of the multi-point feeding / perfuming device, 10 is the slave driving device, 11 is the heating head of the cylinder heating device, 12 is the rack, 13 Is the main driving device, and 14 is the discharge port.

[0013] The laminar flow type blade multi-point feeding / perfuming unit of the present invention, its structure comprises mainly by feeding vibrating conveyor 8, drum, feeding / perfuming device and nozzle thereof, hot air purging device, cylinder heating dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com