Multi-linkage gear shaping quick positioning tool

A multi-gear and positioning tooling technology, which is applied to gear tooth manufacturing devices, belts/chains/gears, gear teeth, etc., can solve problems such as large errors, difficult to guarantee accuracy, and affect the quality of multi-gear products, and achieve positioning accuracy High, easy to operate, suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with accompanying drawing and embodiment:

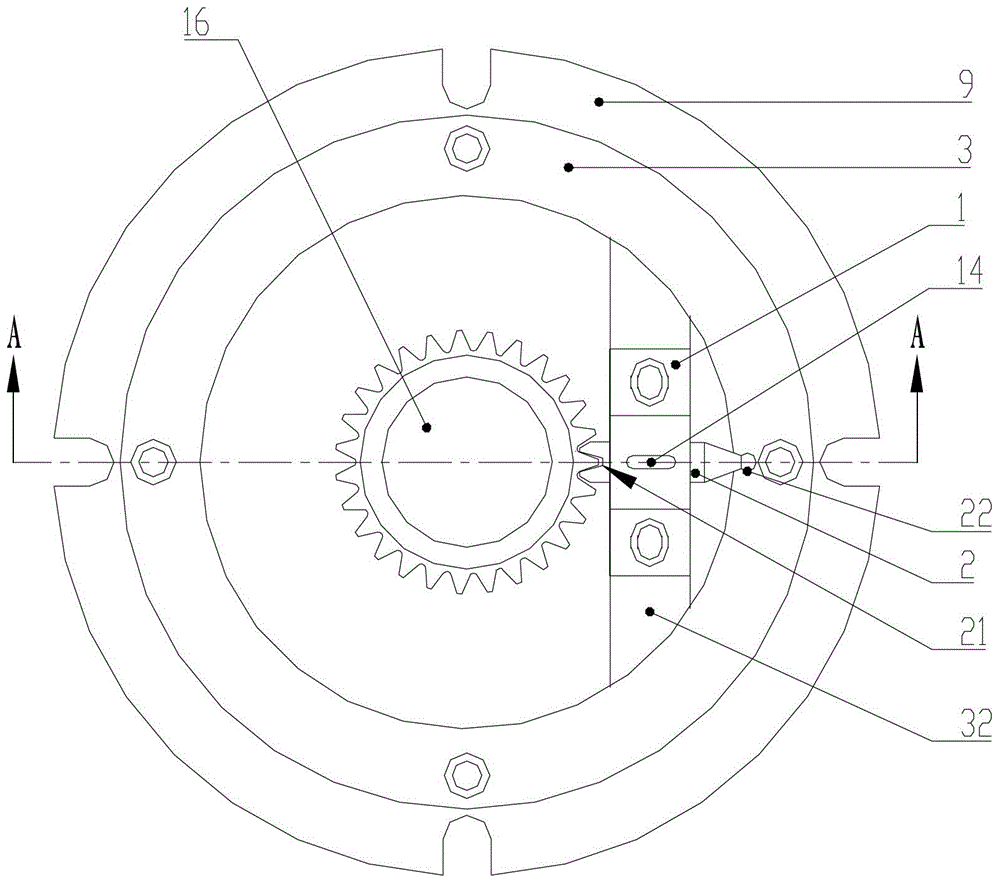

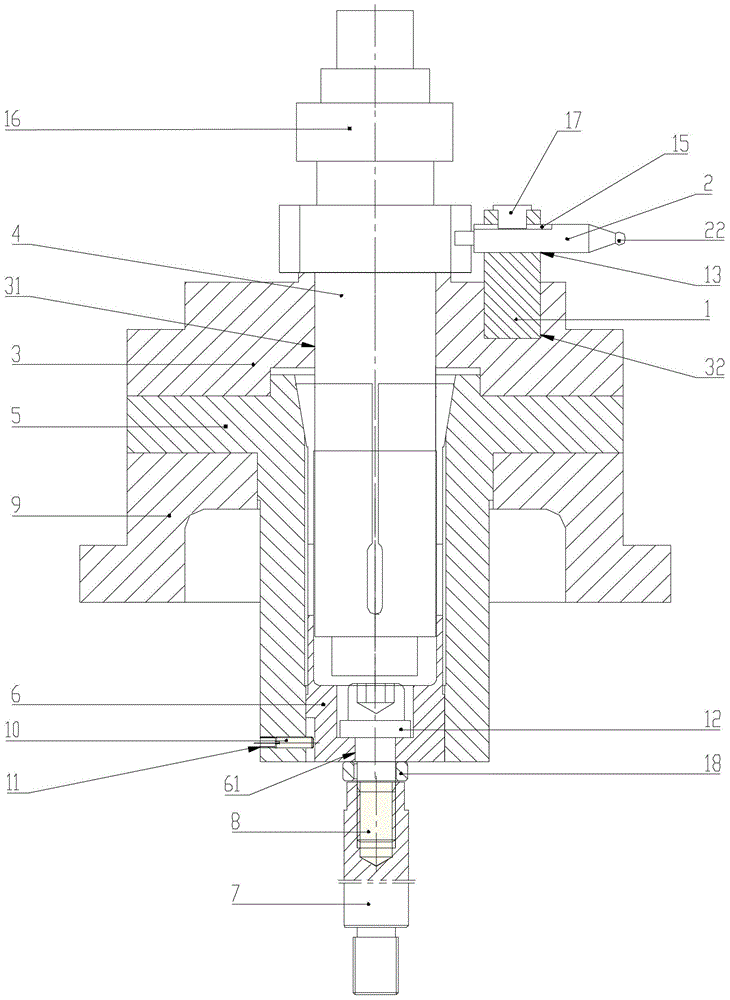

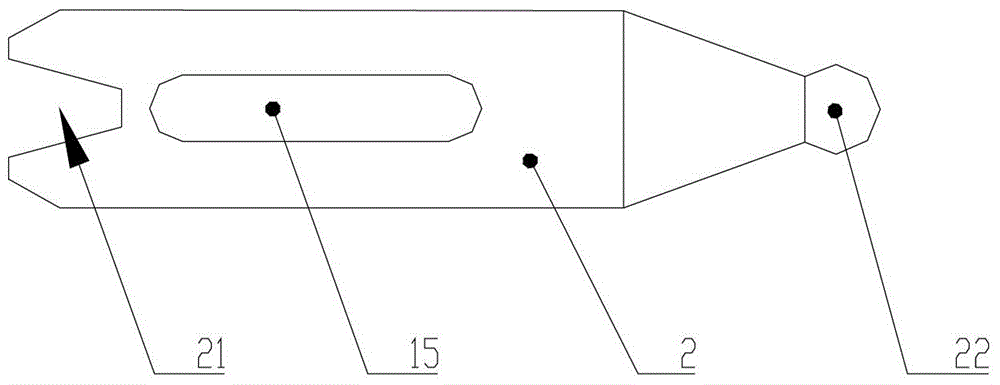

[0030] Such as Figures 1 to 3 As shown, the multi-connected gear shaper quick positioning tool of the present invention includes a sliding seat 1 and a positioning rod 2 arranged on the sliding seat 1. One end of the positioning rod 2 is provided with an opening 21 corresponding to the shape of the gear teeth. One end is provided with a protrusion 22 capable of being inserted into the tooth groove. When processing the first part, first fix the workpiece so that the open end of the positioning rod is stuck on the gear tooth that has been machined, and then insert the protruding end of the positioning rod into the tooth groove of the gear shaper cutter , and then fix the gear shaper cutter, so that the gear shaper cutter and the processed teeth on the part establish a one-to-one correspondence, and measure the processed part. If there is a slight deviation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com