Processing method and processing equipment of epidural anesthesia needle tube

A technology of processing equipment and processing methods, applied in electric processing equipment, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor processing quality, cumbersome processing methods, inconvenient use, etc., and achieve smooth and shiny surfaces. Less processing steps, less fading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described.

[0029] A method for processing an epidural anesthesia needle tube, comprising the steps of:

[0030] (1) Fixed-length cutting, cutting the steel pipe to a specified length;

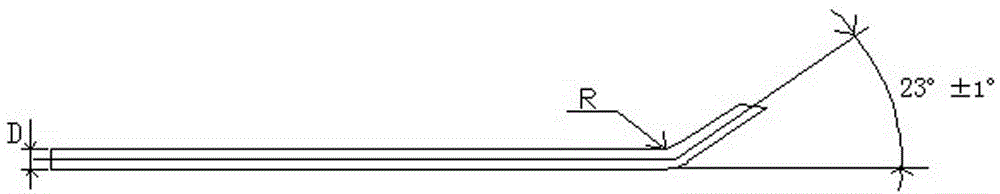

[0031] (2) Elbow, use the elbow clamp to bend one end of the needle tube into a specified arc surface, such as figure 1 shown;

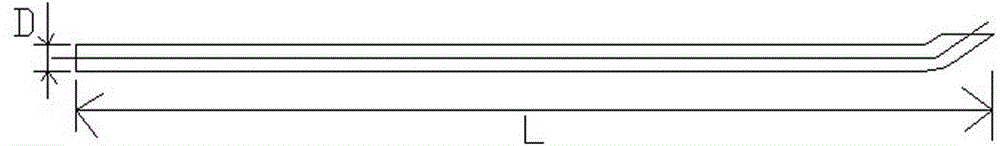

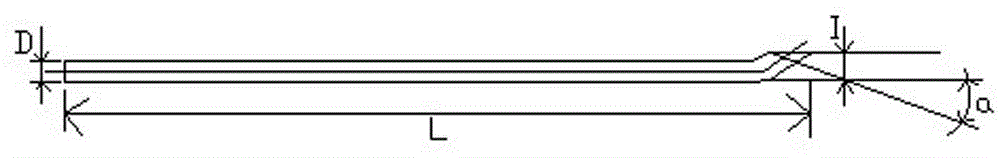

[0032] (3) Cut the oblique opening, start the pipe cutting machine, extend the elbow of the needle tube into the pipe cutting fixture, place the needle tube horizontally, press the rear part of the needle tube against the positioning device, pull the compression handle, and feed the material forward slowly and evenly. After cutting, return to the original position and remove the needle tube, such as figure 2 shown;

[0033] (4) Bevel sharpening, using conductive grinding head for bevel sharpening:

[0034] a. Fix the needle-loading fixture on the worktable that can aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com