Using method for ground linkage table operation and control device of large-scale crane

A linkage table and crane technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of physical and mental injuries of crane workers, reduce safety expenses, operate safely, and ensure normal and safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

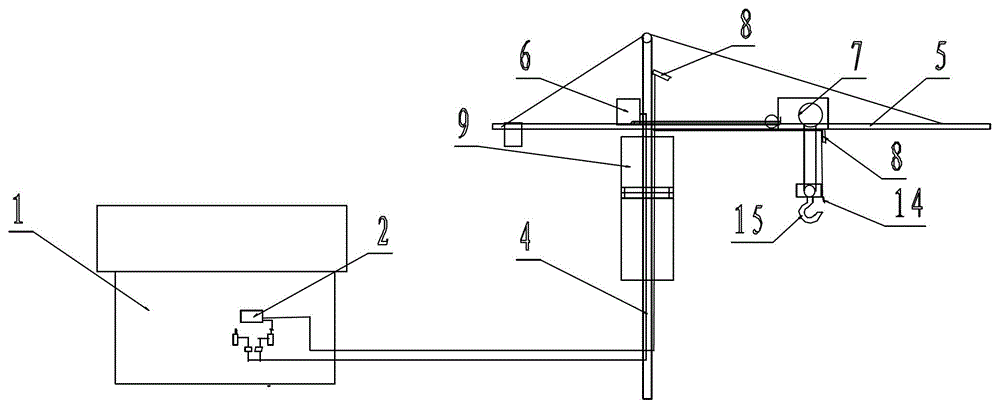

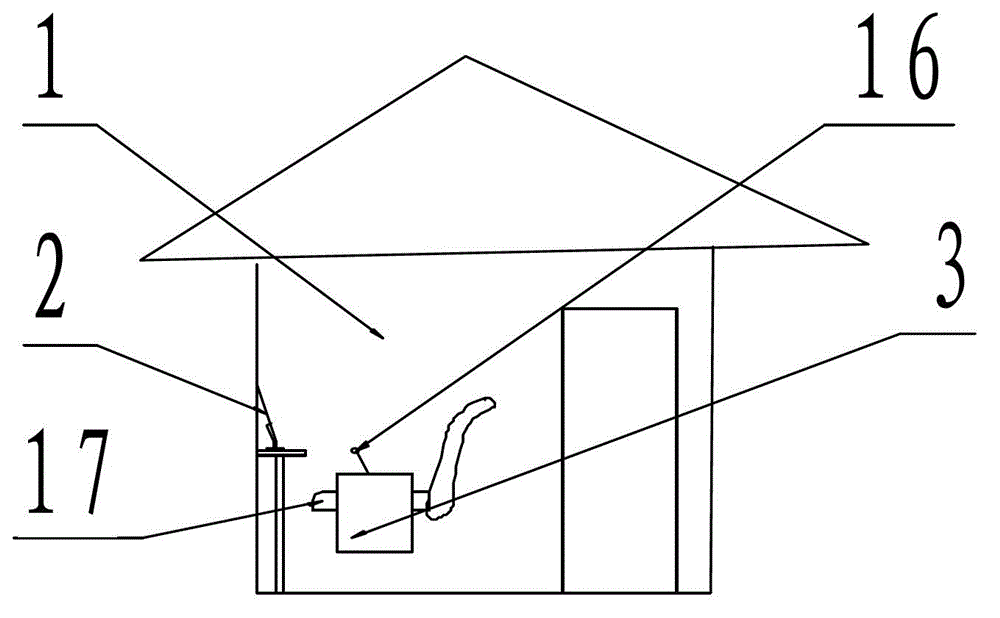

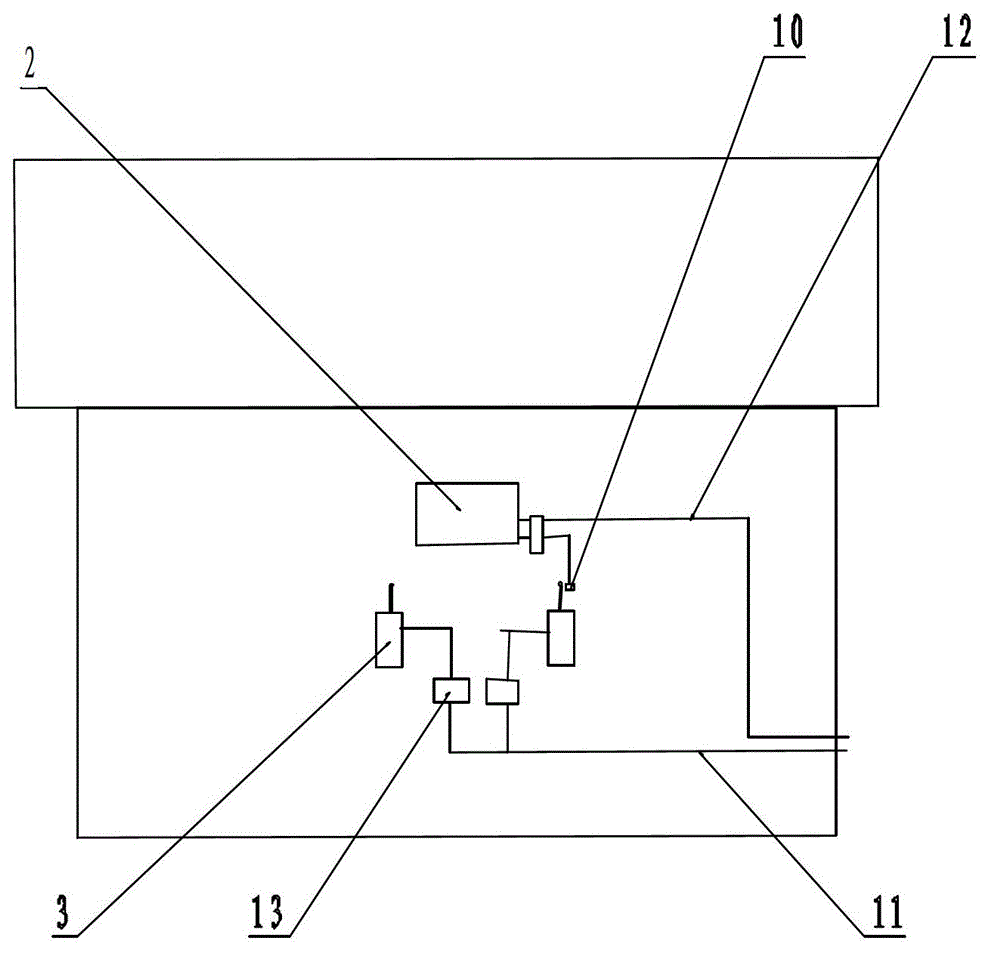

[0022] As shown in the figure; the base side of the crane support frame 4 is provided with a ground control room 1, the upper part of the crane support frame 4 is provided with a slewing assembly 9, and the horizontal boom 5 is arranged horizontally above the slewing assembly 9, and the hoisting section of the cross boom 5 The hoist trolley 7 is arranged horizontally above, and the main distribution box 6 is arranged above the counterweight section of the cross boom 5; the main monitoring camera 8 is arranged on one side of the upper bracket of the slewing assembly 9, and the hoist trolley 7 is installed on at least one side A camera 18, a hook grab 15 is set under the hoisting rope of the hoist trolley 7, a camera and an indicating device 14 are set on the side above the hook grab 15; an operator seat 17 is set in the ground control room 1, and the operator seat 17 Both sides are respectively provided with a linkage platform 3, an operating handle 16 is arranged above the li...

Embodiment 2

[0024] A crane control circuit 11 is set between the linkage table 3 and the main distribution box 6, and contactors 13 are respectively arranged on one side of the linkage table 3; The hoist trolley 7 is provided with a power supply circuit; the host of the computer display 2 is respectively provided with the main monitoring camera 8 and the lifting camera 18, the camera and the indicating device 14, and the monitoring control circuit 12 is set; the host of the computer display 2 and the monitor controller 10 between the signal lines.

Embodiment 3

[0026] In the ground control room 1, the operator turns on the power supply of the crane and the computer monitor 2, follows the instructions of the security commander through the walkie-talkie to lift the position of the cargo, observes the picture of the cargo position on the computer monitor 2 through the main monitoring camera 8, and manually operates the handle 16 And the linkage platform 3 controls the slewing assembly 9 through the crane control circuit 11 to drive the hanger cross arm 5 to rotate to the top of the hoisted goods and stop;

[0027] Observing the picture in the computer monitor 2 through the lifting camera 18 and the main monitoring camera 8, the operator manually operates the operating handle of the linkage platform 3 to control the lifting trolley 7 to run to the top of the lifting goods and stop through the crane control circuit 11;

[0028] Observing the picture in the computer monitor 2 through the camera and the pointing device 14 and the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com