Method for preparing porous carbon based nanomaterial through carbon dioxide conversion

A technology of nanomaterials and carbon dioxide, applied in the direction of carbon nanotubes, nanocarbons, nanotechnology, etc., can solve the problems of poor controllability of carbon-based nanomaterials, and achieve the effect of simple and controllable preparation process, easy industrial production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

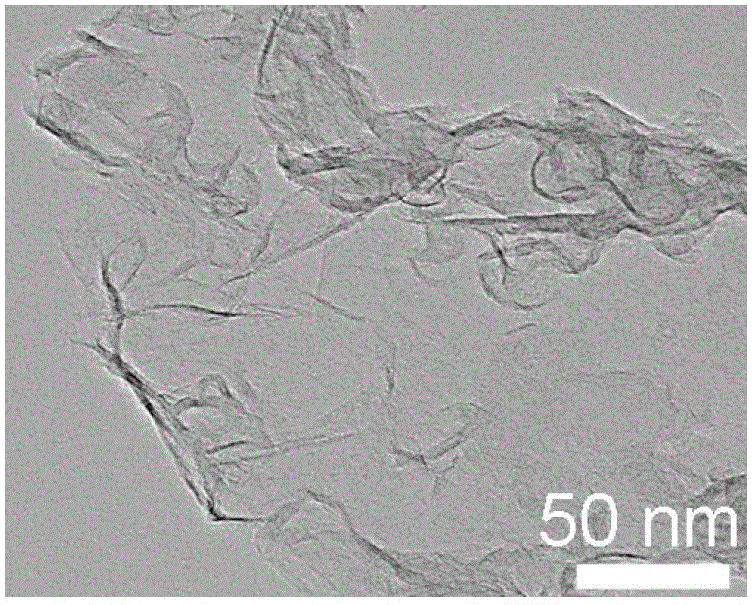

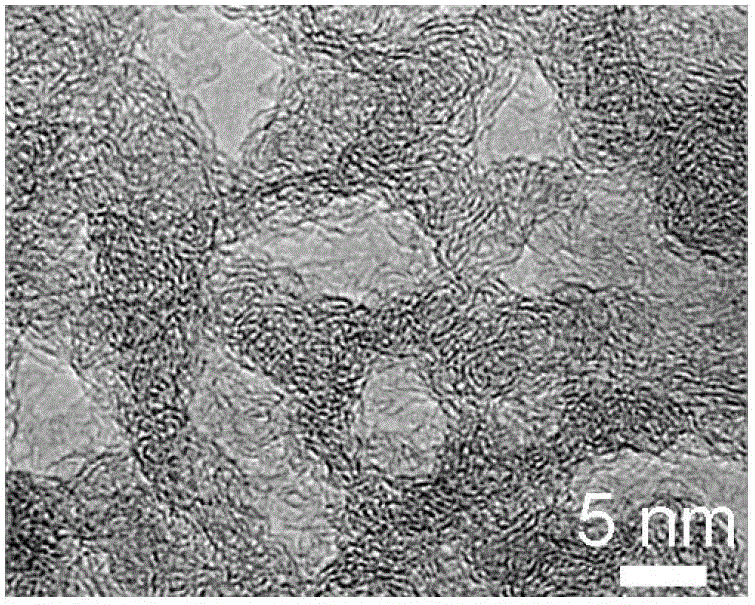

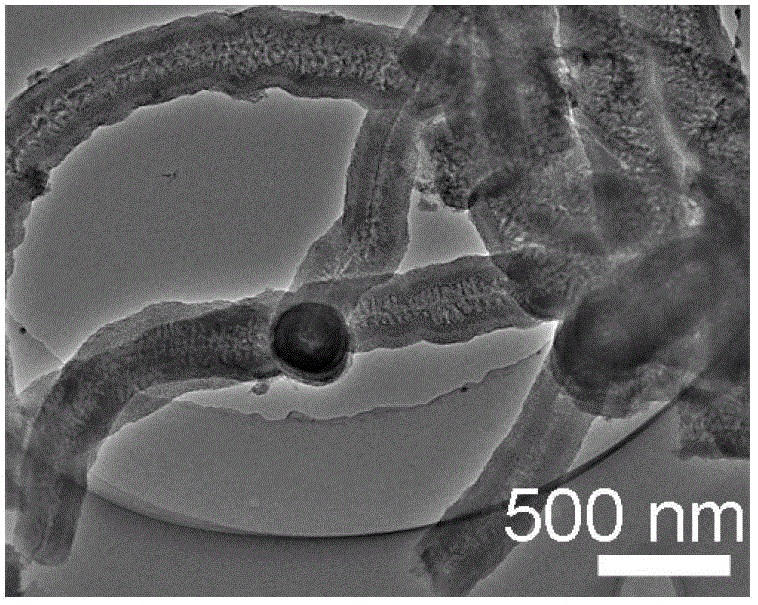

[0028] Put the metal magnesium powder in a high-temperature furnace, raise the temperature to 600°C at a rate of 10° / min under an argon protective atmosphere, and then introduce CO 2 atmosphere, CO 2 The ratio of the gas flow to Ar is 1:1, and the CO is turned off after 30 minutes of reaction 2 Air flow, cooled to room temperature in an argon atmosphere, that is, black powder was obtained. The obtained black powder was reacted with a hydrochloric acid solution with a concentration of 8 mol / L for 12 hours, then fully washed with deionized water until neutral, and dried to obtain porous graphene. in Figure 1a Indicating that graphene has a sheet-like structure, Figure 1b It shows that graphene has a rich pore structure. Figure 2a An atomic force microscope image of porous graphene, Figure 2b It is proved that the graphene sheet thickness is about 0.7nm. image 3 The middle curve (a) is the pore size distribution diagram of porous graphene, and the average pore size is 7...

Embodiment 2

[0030] Put the metal magnesium powder in a high-temperature furnace, raise the temperature to 500°C at a rate of 5° / min under an argon protective atmosphere, and then introduce CO 2 atmosphere, CO 2 The ratio of the gas flow to Ar is 4:1, and the CO is turned off after 60 minutes of reaction 2 Air flow, cooled to room temperature in an argon atmosphere, that is, black powder was obtained. The obtained black powder was reacted with a nitric acid solution with a concentration of 2 mol / L for 24 hours, then fully washed with deionized water until neutral, and dried to obtain porous graphene.

Embodiment 3

[0032] Put the metal magnesium strip in a high-temperature furnace, raise the temperature to 650°C at a rate of 8° / min under an argon protective atmosphere, and then introduce CO 2 atmosphere, CO 2 The ratio of the gas flow to Ar is 1:4, and the CO is turned off after 5 minutes of reaction 2 Air flow, cooled to room temperature in an argon atmosphere, that is, black powder was obtained. The obtained black powder was reacted with a sulfuric acid solution with a concentration of 6 mol / L for 20 h, then fully washed with deionized water until neutral, and dried to obtain porous graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com