A method for refining and purifying polyoxymethylene dialkyl ether

A formaldehyde dialkyl ether and product technology, which is applied in the refining and extraction process field of diesel fuel additive-polyoxymethylene dialkyl ether, can solve the problems of poor extraction efficiency, poor extraction rate of extraction unit and poor purity of extracted products, etc. High operational safety, high extraction efficiency, and simple process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

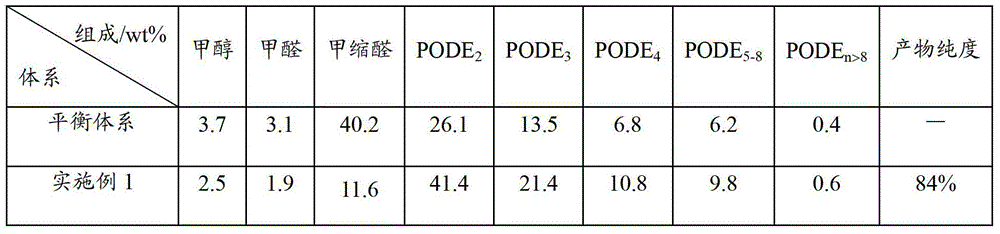

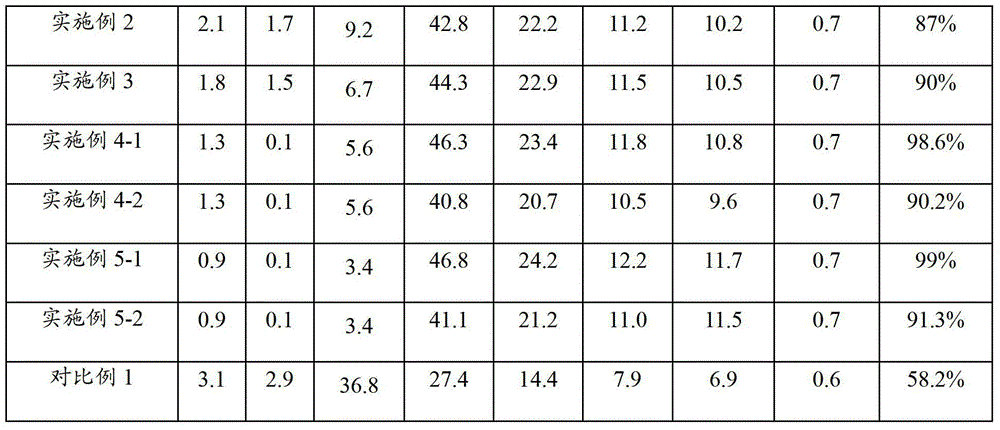

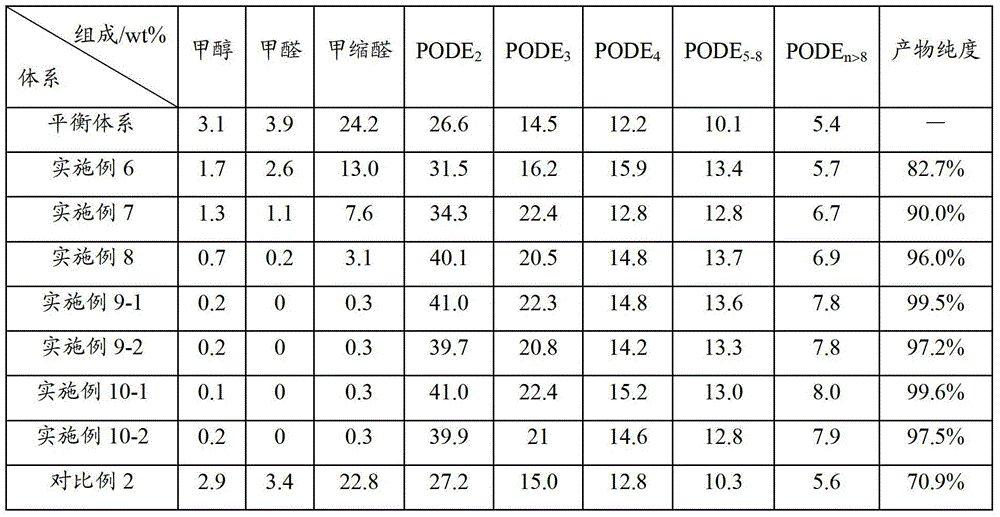

Embodiment 1

[0048] This embodiment provides a method for refining and purifying polyoxymethylene dialkyl ether, specifically:

[0049] S1. Add aqueous sodium hydroxide solution to the equilibrium product of polyoxymethylene dialkyl ether, the input amount of sodium hydroxide is 20% of the mass of the equilibrium product, the mass concentration of aqueous sodium hydroxide solution is 10%, and heat to 50°C for reaction , for 2 hours;

[0050] S2, the mixture obtained in step S1 is left to stand for stratification, the upper liquid is collected, and anhydrous K accounting for 10% of the upper liquid mass is added 2 CO 3 Drying is carried out, and the filtrate is obtained after the drying is completed;

[0051] S3. Carry out graded atmospheric distillation on the filtrate, distill off the fraction before 60°C, the initial boiling point ~60°C is the unreacted raw material (formaldehyde, methanol and methylal), and the fraction collected at ~110°C is the dimerization product (PODE 2 ), the ...

Embodiment 2

[0053] This embodiment provides a method for refining and purifying polyoxymethylene dialkyl ether, specifically:

[0054] S1. Add aqueous sodium hydroxide solution to the equilibrium product of polyoxymethylene dialkyl ether, the input amount of sodium hydroxide is 20% of the mass of the equilibrium product, the mass concentration of aqueous sodium hydroxide solution is 20%, and heat to 50°C for reaction , for 2 hours;

[0055] S2, the mixture obtained in step S1 is left to stand for stratification, the upper liquid is collected, and anhydrous K accounting for 10% of the upper liquid mass is added 2 CO 3 Drying is carried out, and the filtrate is obtained after the drying is completed;

[0056] S3. First carry out atmospheric distillation on the filtrate, distill out the fraction before 60°C, the initial boiling point ~ 60°C is the unreacted raw material (formaldehyde, methanol and methylal); then use vacuum distillation, the vacuum degree is 0.01MPa , the fraction collect...

Embodiment 3

[0058] This embodiment provides a method for refining and purifying polyoxymethylene dialkyl ether, specifically:

[0059] S1. Add aqueous sodium hydroxide solution to the equilibrium product of polyoxymethylene dialkyl ether, the input amount of sodium hydroxide is 20% of the mass of the equilibrium product, the mass concentration of aqueous sodium hydroxide solution is 30%, and heat to 50°C for reaction , for 2 hours;

[0060] S2, the mixture obtained in step S1 is left to stand for stratification, the upper liquid is collected, and anhydrous K accounting for 10% of the upper liquid mass is added 2 CO 3 Carry out drying, obtain filtrate after drying;

[0061] S3. Perform atmospheric distillation on the filtrate, the temperature at the bottom of the tower is 100° C., and the reflux ratio is 1. The production liquid at the top of the tower consists of methanol, methylal and a small amount of dimerization products; Then carry out fractional atmospheric pressure distillation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com