Method for extracting dragon fruit peel polysaccharides

A technology of pitaya peel and an extraction method, which is applied in the field of deep processing of fruits, can solve the problems of the destruction of the activity of pitaya polysaccharides, the reduction of the antioxidant properties of the pitaya polysaccharides and the ability of scavenging free radicals, etc. The effect of extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The extraction method of dragon fruit peel polysaccharide, described method comprises the following steps:

[0029] (1) Take 20g of clean dragon fruit peel, chop it up, add 240mL of water, the temperature of the water is 22°C, make a pulp, get the dragon fruit peel slurry, centrifuge, and take the supernatant;

[0030] (2) Add 3.5 times the volume of ethanol solution to the supernatant obtained in step (1), let stand for 100min, centrifuge, collect the precipitate, wash 3 times with ethanol solution, centrifuge, collect the precipitate, and obtain the pitaya peel crude polysaccharide;

[0031] (3) The pitaya peel crude polysaccharide obtained in step (2) is added to 240 mL of water at a temperature of 22° C., stirred and dissolved to obtain an aqueous solution of the pitaya peel crude polysaccharide;

[0032] (4) chloroform and n-butanol are uniformly mixed with a volume ratio of 3.5:1 to obtain the sevage reagent;

[0033] (5) get the pitaya peel crude polysaccharide ...

Embodiment 2

[0038] (1) Take 20g of clean dragon fruit peel, chop it, add 360mL of water, the temperature of the water is 28°C, make a pulp, get the dragon fruit peel slurry, centrifuge, and take the supernatant;

[0039] (2) Add 4.5 times the volume of ethanol solution to the supernatant obtained in step (1), let stand for 150min, centrifuge, collect the precipitate, wash 4 times with ethanol solution, centrifuge, collect the precipitate, and obtain the pitaya peel crude polysaccharide;

[0040] (3) adding the pitaya peel crude polysaccharide obtained in step (2) into 360 mL of water at a temperature of 28° C., stirring and dissolving to obtain an aqueous solution of pitaya peel crude polysaccharide;

[0041] (4) chloroform and n-butanol are mixed uniformly with a volume ratio of 4.5:1 to obtain the sevage reagent;

[0042] (5) get the pitaya peel crude polysaccharide aqueous solution that step (3) obtains and join in the sevage reagent that obtains in step (4), the volume ratio of descri...

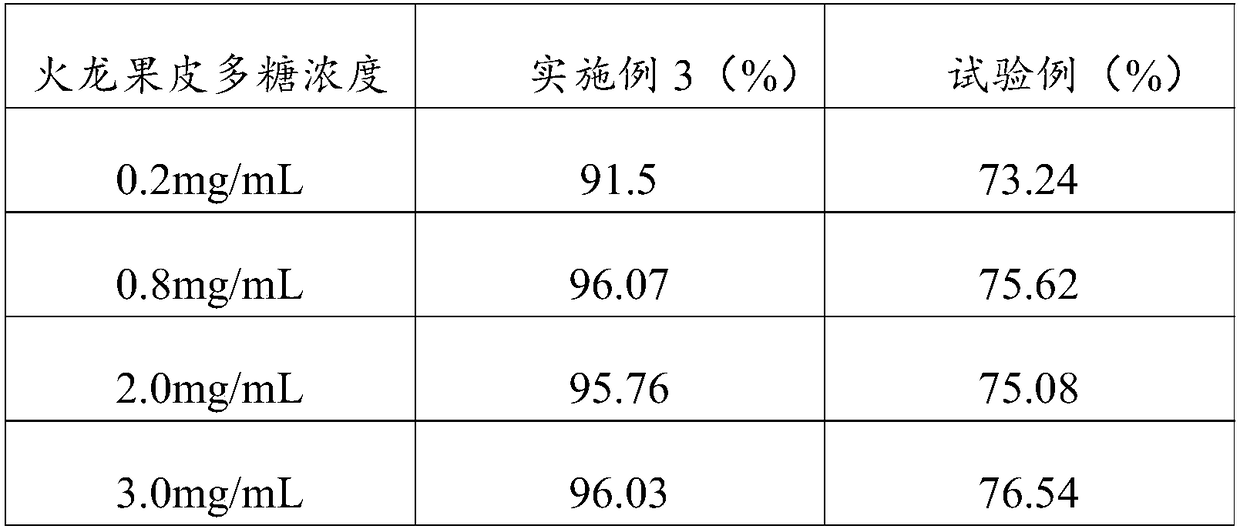

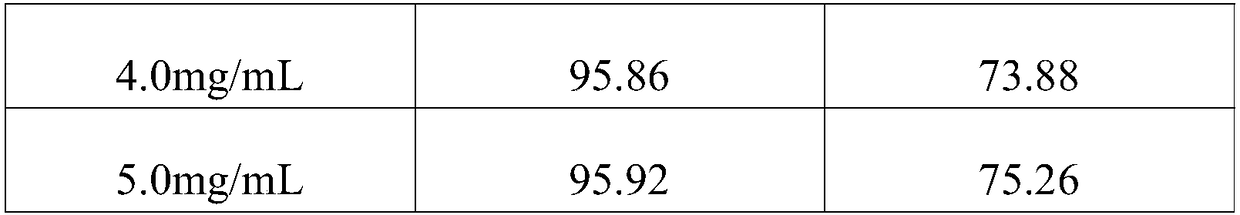

Embodiment 3

[0047] The extraction method of dragon fruit peel polysaccharide, described method comprises the following steps:

[0048] (1) Take 20g of clean pitaya peel, chop it up, add 300mL of water, the temperature of the water is 25°C, beat for 5 minutes to obtain pitaya peel pulp, centrifuge, and take the supernatant;

[0049] (2) Adding 4 times of volume to the supernatant obtained in step (1) is a 65% ethanol solution, left to stand for 120min, and is centrifuged for 10min at a speed of 6000r / min, collects the precipitate, and uses a volume fraction of Wash with 65% ethanol solution for 3 times, centrifuge at a speed of 6000r / min for 10min, collect the precipitate, and obtain the crude polysaccharide from pitaya peel;

[0050] (3) The pitaya peel crude polysaccharide obtained in step (2) is added to 300 mL of water at a temperature of 25° C., stirred and dissolved to obtain the pitaya peel crude polysaccharide aqueous solution;

[0051] (4) chloroform and n-butanol are mixed unifo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com