Nano cerium oxide/epoxy composite paint and preparation method thereof

A nano-cerium oxide and composite coating technology, applied in the coating field, achieves the effects of good electrochemical performance and optical performance, good dispersibility and compatibility, and increased stability and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

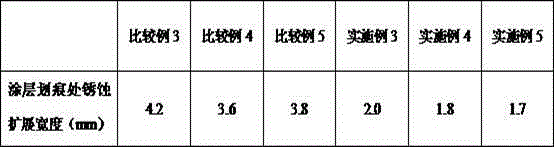

Examples

Embodiment 1

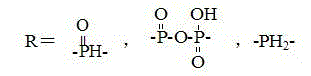

[0045] Example 1: Weigh 10g of nano-cerium oxide into a three-necked flask, dilute with 100g of mixed solvent (water:ethanol=1:9), and then add 1% NDZ-201 titanate couple of powder mass to it The coupling agent is fully stirred for 2 hours, heated to 85° C., mixed and stirred and refluxed for 5 hours, and then the mixture is suction filtered, dried, ground, and sieved to obtain modified particles of nano-cerium oxide.

Embodiment 2

[0046] Example 2: Weigh 10g of nano-cerium oxide into a three-necked flask, dilute with 100g of mixed solvent (water:ethanol=1:9), and then add 4% NDZ-401 titanate of powder mass to it The coupling agent is fully stirred for 2 hours, heated to 85° C., mixed and stirred and refluxed for 5 hours, and then the mixture is suction filtered, dried, ground, and sieved to obtain modified particles of nano-cerium oxide.

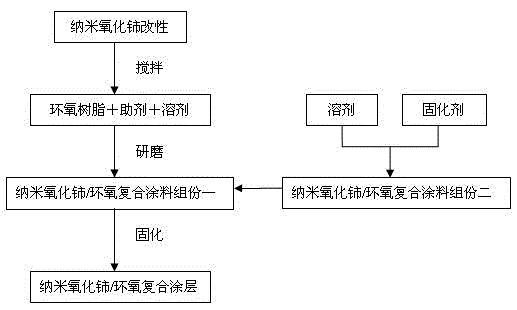

[0047] Preparation of nano-cerium oxide / epoxy composite coating:

Embodiment 4

[0055] Add 5g of nano-cerium oxide modified according to Example 1 into 69g E51 epoxy resin, 0.5g Anti-Terra-204 dispersant, 0.5g BENTONE27 anti-settling agent and 25g xylene in a container, and stir for 40 minutes; Grind these epoxy resin mixtures to obtain component one of nano-cerium oxide / epoxy composite coating; in another container, dissolve 50g polyamide curing agent in 50g toluene to make nano-cerium oxide / epoxy composite Component two of the coating; add component two to component one in the ratio of component one: component two=100:80, and cure at room temperature for 30 minutes to 7 days to form a nano-cerium oxide / epoxy composite coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com