Hydraulic fill curing agent mixing equipment

A technology for filling silt and curing agent, which is used in soil protection, construction, infrastructure engineering, etc., can solve the problems affecting the wide-scale popularization and application of reinforcement methods, polluting the land environment, and high economic cost of curing agents, and can shorten land reclamation. time, reducing the cost of land-building, and improving the quality of land-building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

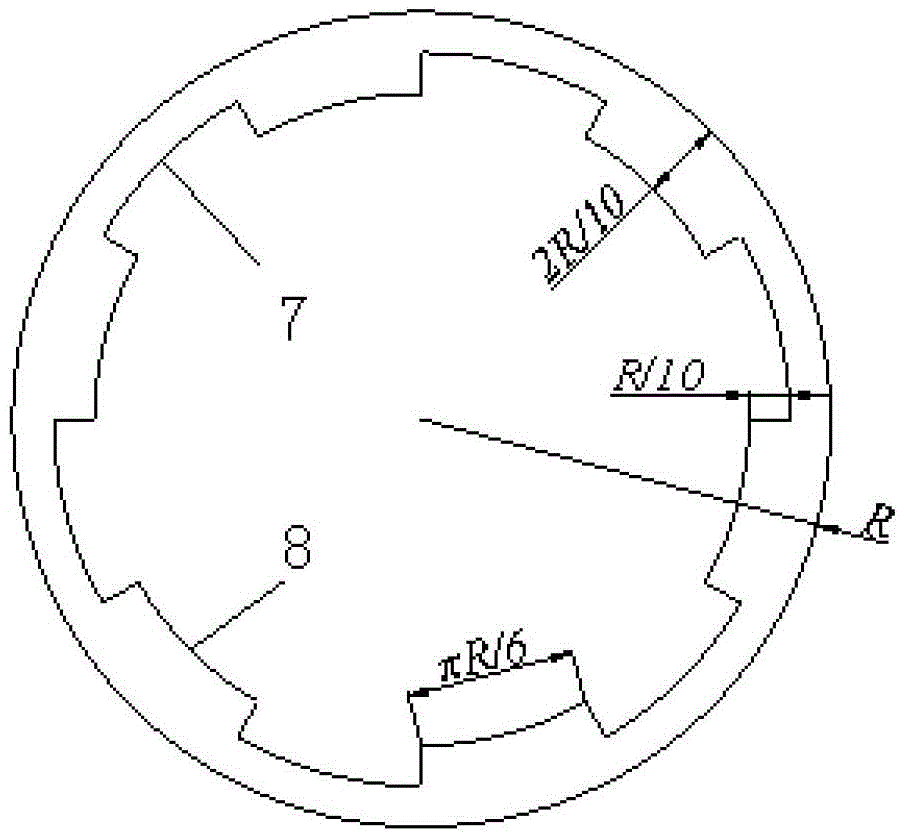

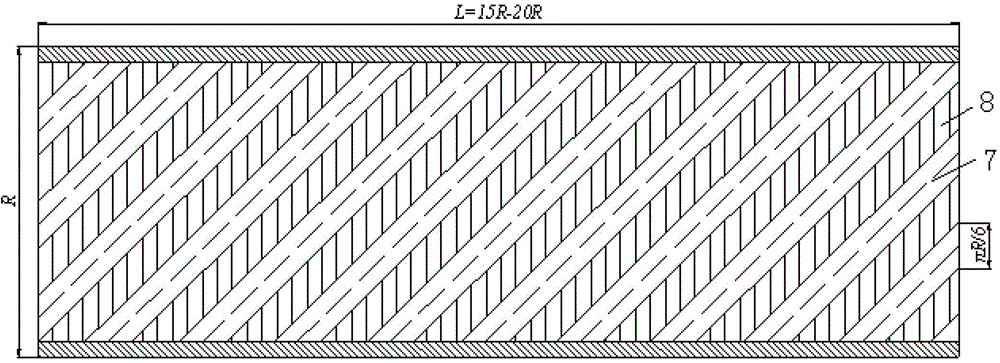

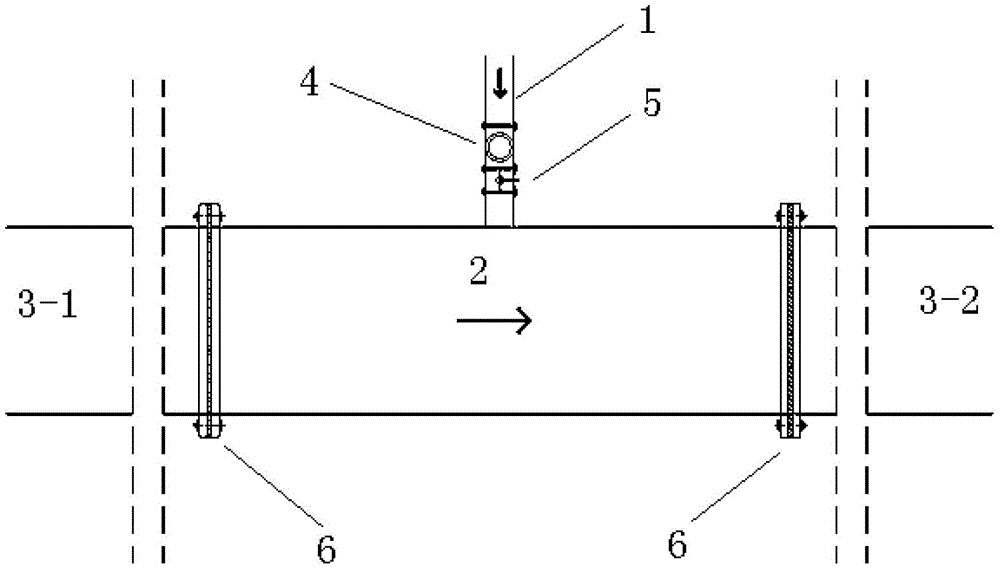

[0024] Embodiment 1, the curing agent mixing equipment of dredged mud soil, with reference to figure 1 , figure 2 and image 3 The two ends of the curing agent mixing equipment for dredging and filling mud soil are connected with the mud delivery pipeline 3-1, 3-2; the main body of the curing agent mixing equipment for this dredging and filling mud soil is a section of rifle line pipeline 2; The curing agent delivery pipeline 1 is connected to the rifling pipeline 2 from the side. A flow meter 4 and a valve 5 are provided at the connection between the curing agent delivery pipeline and the rifling pipeline; flanges 6 are provided at the connection between the rifling pipeline 2 and the mud delivery pipeline 3-1, 3-2. The height difference between Yinxian 7 and Yangxian 8 is R / 10( R is the radius of the rifling pipeline), the negative line 7 and the positive line 8 are arranged at intervals and spirally distributed along the pipeline, and the widths of the negative line 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com