Land lever variable-power control system

A power control and leveling technology, applied in engine control, electrical control, fuel injection control, etc., can solve the problem of high power loss, and achieve the effect of reducing fatigue, reducing labor intensity, strong economy and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

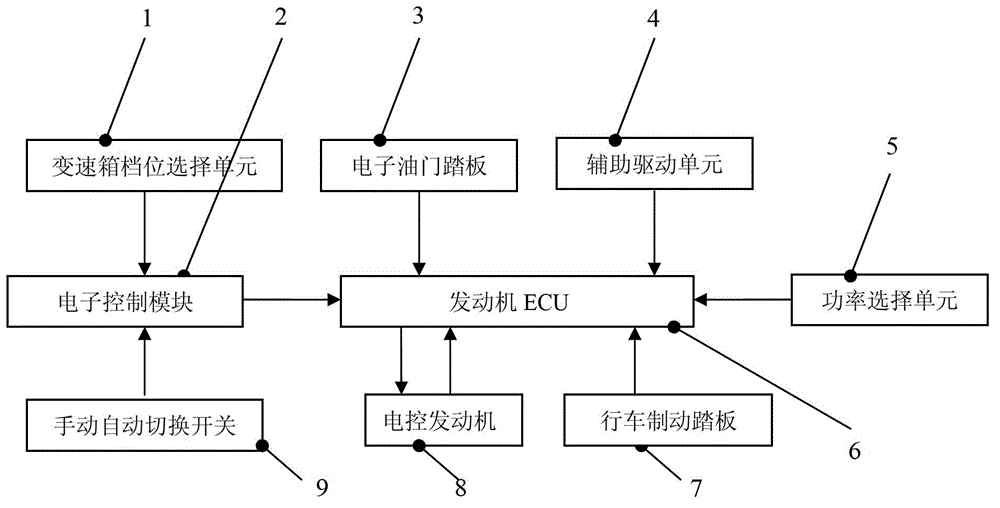

[0013] Such as figure 1 As shown, the motor grader variable power control system includes a gearbox gear selection unit 1, an electronic control module 2, a transmission power selection unit 5, an engine ECU 6, and a manual / automatic switch 9. The engine ECU 6 can recognize the position signal of the electronic throttle sensor, and according to the sensor The signal controls the cycle fuel injection quantity of the electronically controlled engine 8, and the power selection unit 5 can realize the operation of the engine in different power modes by controlling the engine ECU6 through the power selection unit 5 and the manual and automatic switching switch 9. In the automatic control mode, the electronic control module 2 can receive and identify the shifting Gear position selection signal, the gear position information is transmitted to the engine ECU 6, and the engine ECU 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com