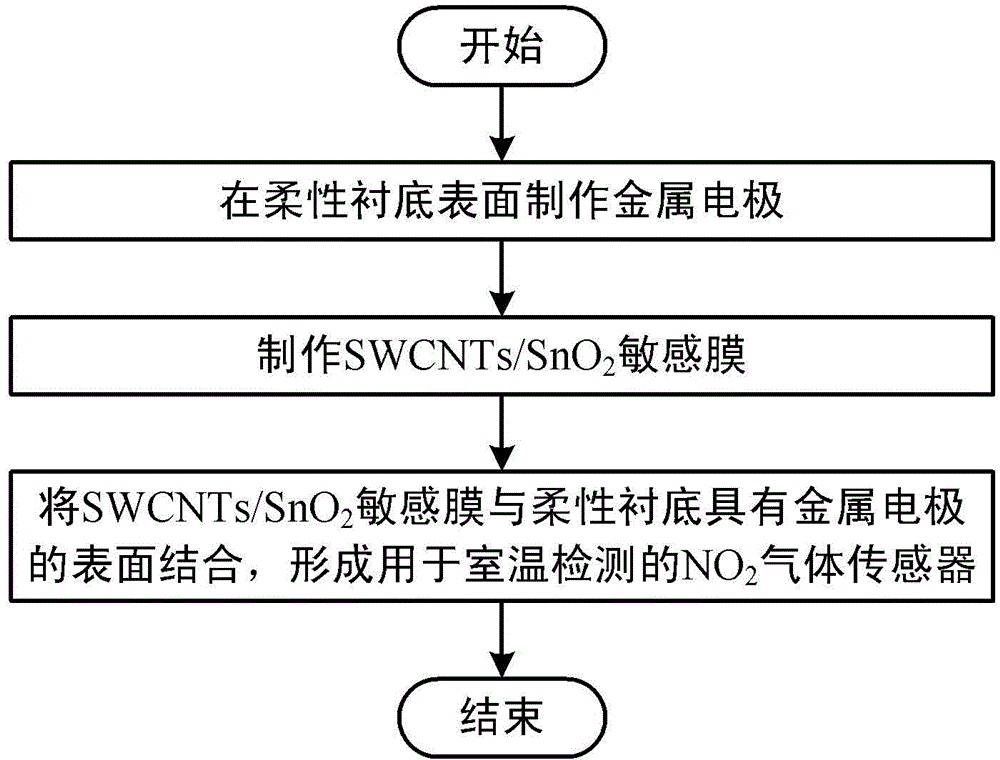

Manufacturing method of NO2 gas sensor used for room temperature detection

A technology of gas sensor and manufacturing method, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of uneven distribution, poor adhesion between sensitive materials and flexible substrates, etc., and achieve the effect of uniform distribution and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0029] The technical idea adopted in the present invention is as follows: CO undergoes disproportionation reaction under high pressure to generate carbon nanotubes, mixes carbon nanotubes with organometallic solution 2-hexyl stannous hexanoate, and ultrasonically oscillates for 1.5 to 2.5 hours, preferably for 2 hours. Hours, a uniformly mixed suspension was obtained, and then the suspension was coated on SiO by spin coating, drop coating, dip coating or screen printing. 2 On the substrate, dry and evaporate the solvent in the coating, and then calcinate at high temperature for 0.5 hours to 4 hours to obtain composite SWCNTs / SnO 2 Sensitive film, and use HF acid to etch off the lower layer of SiO 2 , separate the sensiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com