Combined type sealing cover and open-type axial flow threshing system using same

A sealed cover and combined technology, which is applied to threshing equipment, applications, cutters, etc., can solve the problems of the sealed cover being unable to achieve multiple uses in one machine, single harvested variety, heavy workload, etc., to expand harvested varieties and increase capacity. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

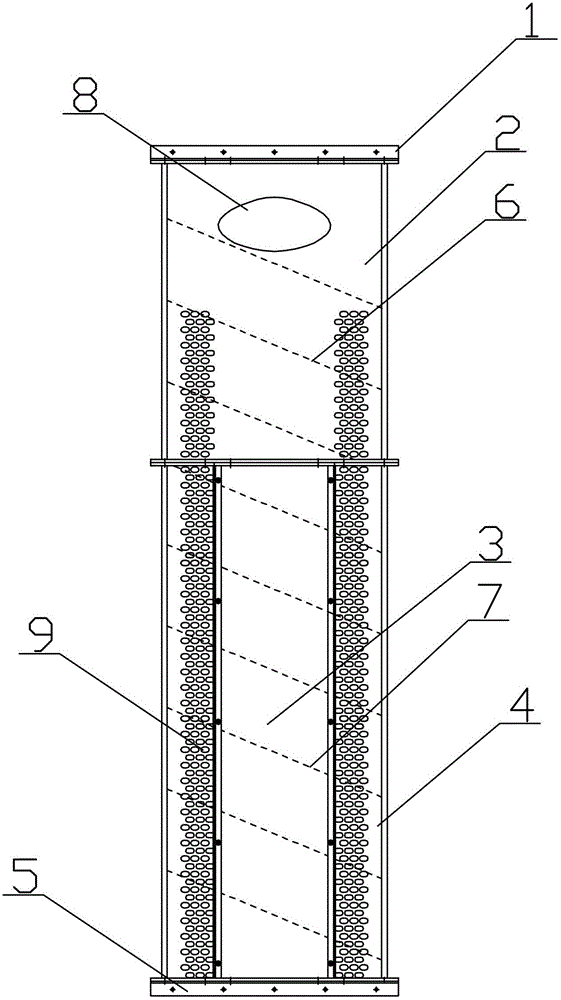

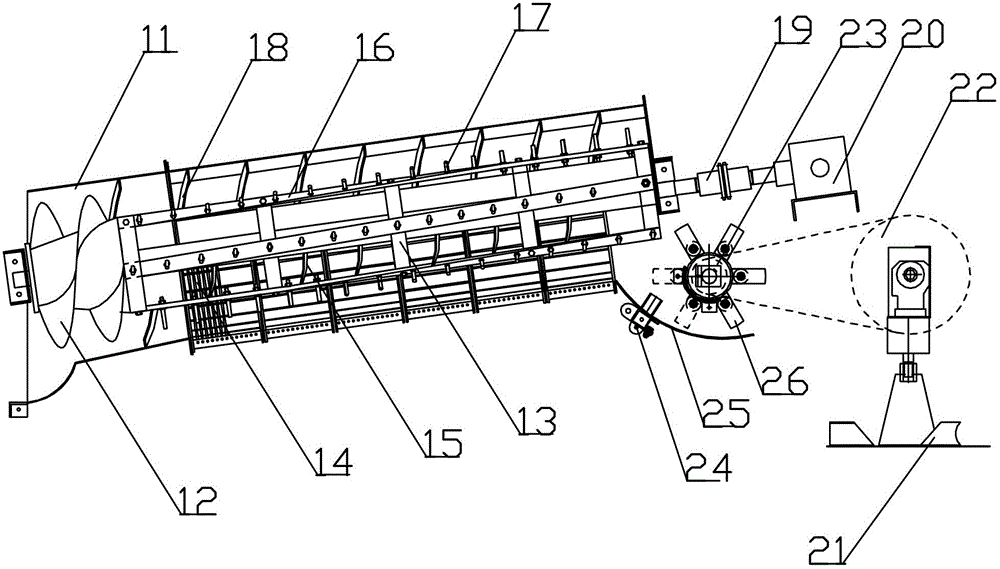

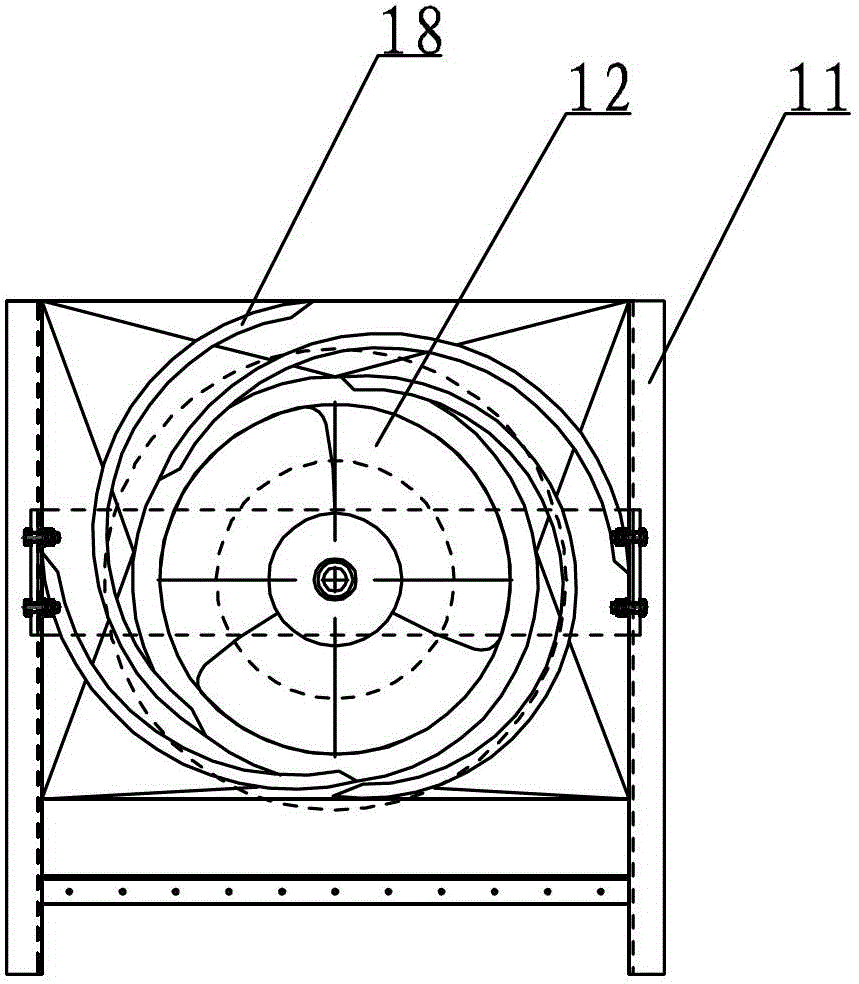

[0016] Specific implementation mode one: combine figure 1 Describe this embodiment, the combined seal cover of this embodiment comprises front part seal plate 1, front part seal cover shell 2, rear part intermediate seal cover shell 3, rear part seal cover shell 4 on both sides, rear seal Plate 5, a plurality of front guide vanes 6 and a plurality of rear intermediate guide vanes 7, the front sealing cover shell 2 is provided with a residual recovery system interface 8, the front sealing plate 1, the front sealing cover The body 2, the rear middle sealing cover shell 3 and the rear sealing plate 5 are sequentially connected, the sealing cover shells 4 on both sides of the rear part are arranged on both sides of the rear middle sealing cover shell 3, and a plurality of front guide vanes 6 is obliquely arranged on the front seal cover shell 2, and a plurality of rear intermediate guide vanes 7 are obliquely arranged on the rear intermediate seal cover shell 3, and the plurality ...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 Describe this embodiment, the left end of each front guide vane 6 of this embodiment is inclined forward, and the included angle between each front guide vane 6 and the horizontal plane is 20°-30°, each rear The left end of the middle guide vane 7 is inclined forward, and the angle between each rear middle guide vane 7 and the horizontal plane is 20°-30°. With such arrangement, multiple front guide vanes 6 make the crops entering at the front end move quickly to the threshing chamber, and reduce the feeding resistance at the front part. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination figure 1 Describe this embodiment, have a plurality of long holes 9 for separating grains on the sealing cover casing 4 on both sides of the rear portion of this embodiment. In this way, the rear middle sealing cover housing 3 is divided into three parts in the middle and both sides. The inside of the rear middle sealing cover housing 3 is welded with a fixed rear middle guide vane 7, because it is in the combined sealing cover. The upper part, its angle is not conducive to the grain falling on it, so there is no elongated hole on the rear middle sealing cover shell 3, and the sealing cover shell 4 on both sides of the rear part is processed with long holes that are conducive to the separation of grains 9. When the crops are conveyed backward, the grains that come off will be separated from the long holes 9, which quickly reduces the workload of the open axial flow threshing drum 13 and its lower concave grid screen 14, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com