Ultrafine grinding system

A technology of ultra-fine pulverization and pulverizing motor, applied in grain processing and other directions, can solve the problems of restricted development and unsatisfactory pulverization effect, and achieve the effect of prolonging maintenance period, simple structure and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

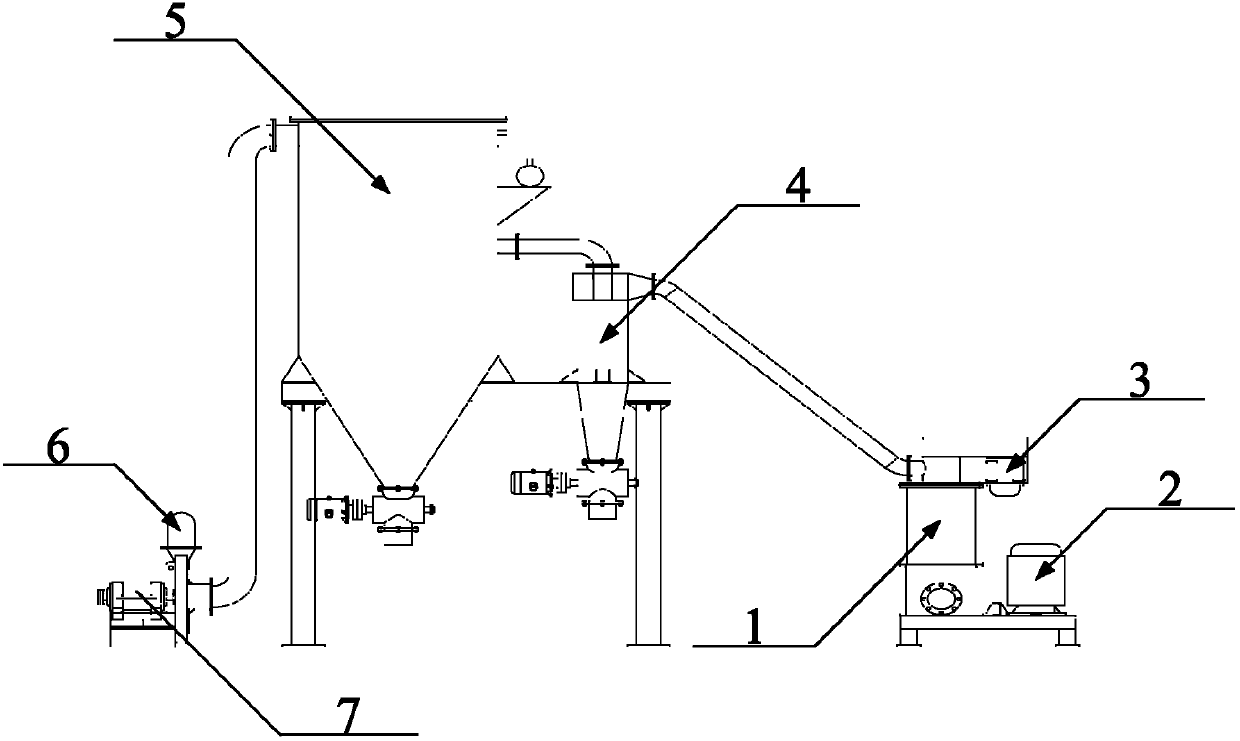

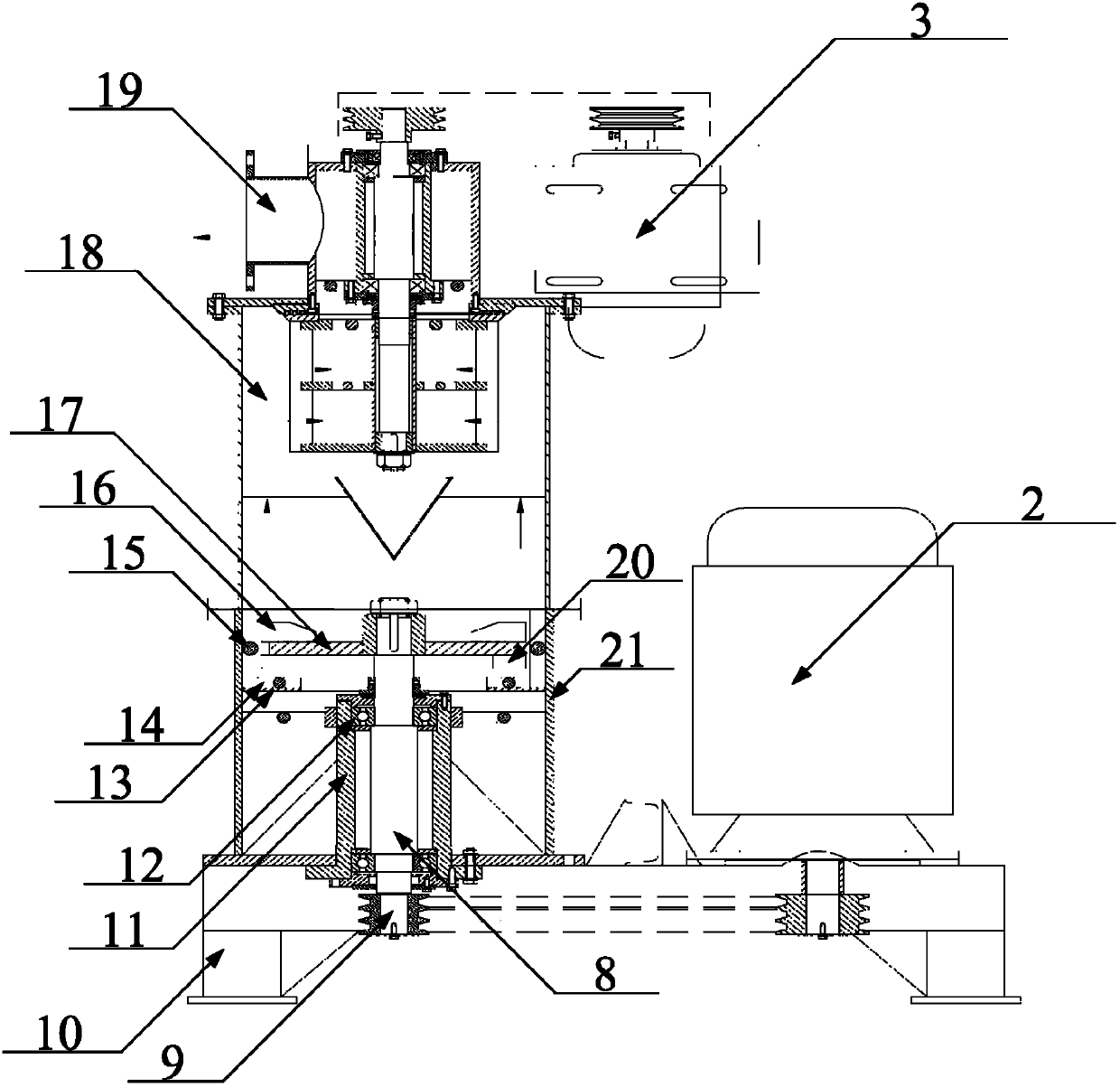

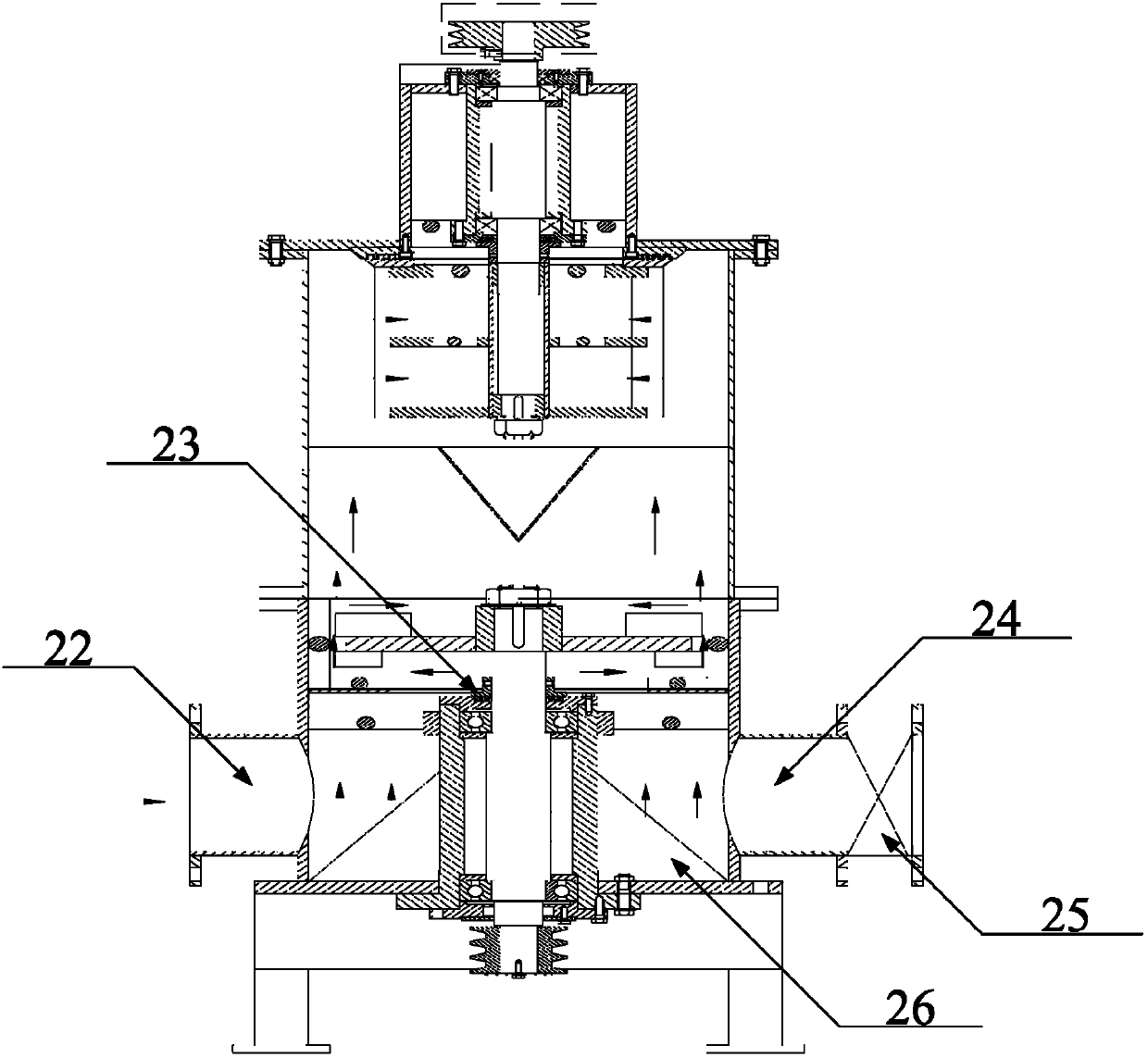

[0030] Such as figure 1 , 2 , 3, 4, and 5, the ultrafine pulverization system includes a pulverization main body 1, which is also connected with a pulverization motor 2 and a classification electrode 3, and which is also connected with a vortex cyclone collector 4, Pulse belt dust collector 5 and high-pressure induced draft fan 7, described high-pressure induced draft fan 7 is also provided with muffler 6; Described pulverizing main body 1 comprises the ultra-fine impact mill that is arranged on the lower end and is connected with pulverizing motor 2 by belt pulley 9, in A classifier 18 is also fixed on the upper end of the ultra-fine impact mill, and the classifier 18 is connected with the classifying motor 3 through a belt pulley.

[0031] The lower end of the above-mentioned ultra-fine impact mill is provided with a support 10 for supporting the impact mill. The upper and lower ends of the main shaft 8 are respectively fixed with an impact disc 17 and a pulley 9, and a be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com