Manufacturing technology of retaining snap ring for multi-piece small-sized engineering wheel and die

A manufacturing process and multi-piece technology, applied in the field of multi-piece lock ring manufacturing process and special mold for small wheels, can solve the problems of low material utilization rate, high manufacturing cost, low production efficiency, etc., and achieve high production efficiency, The effect of improving product quality and improving workpiece shape and dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

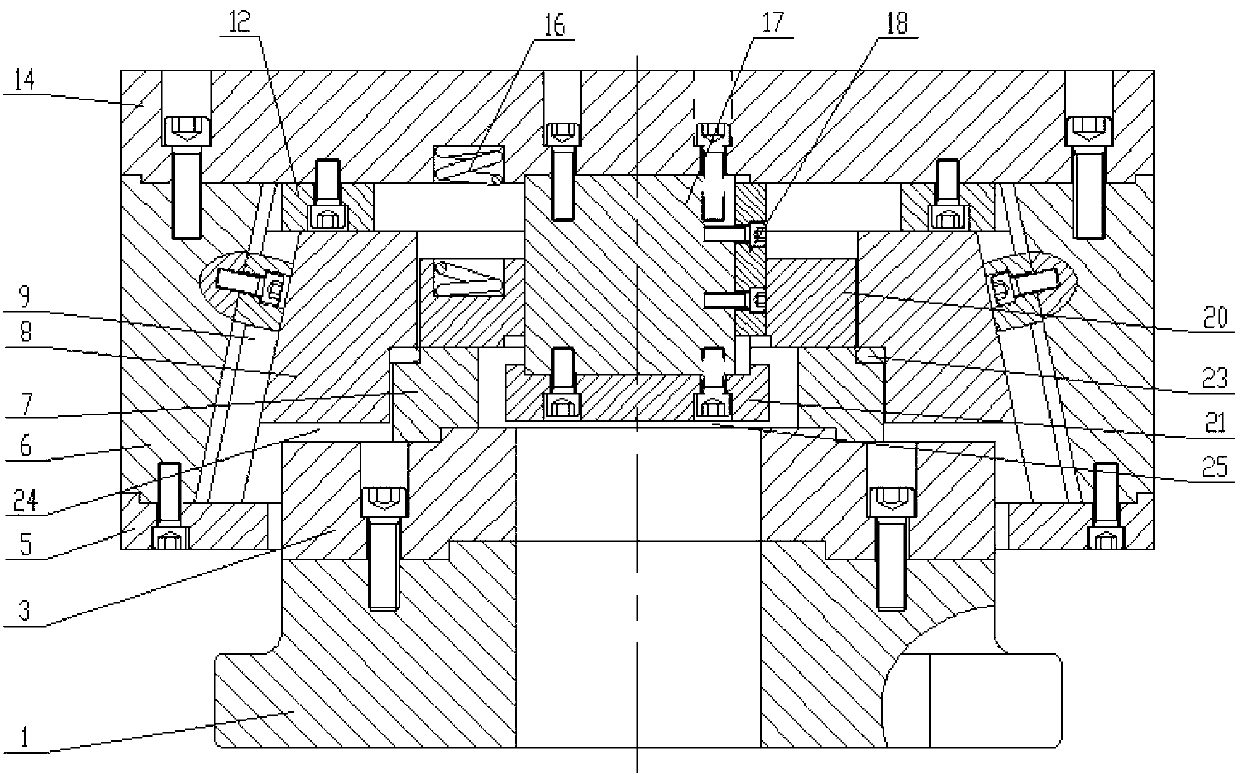

[0039] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

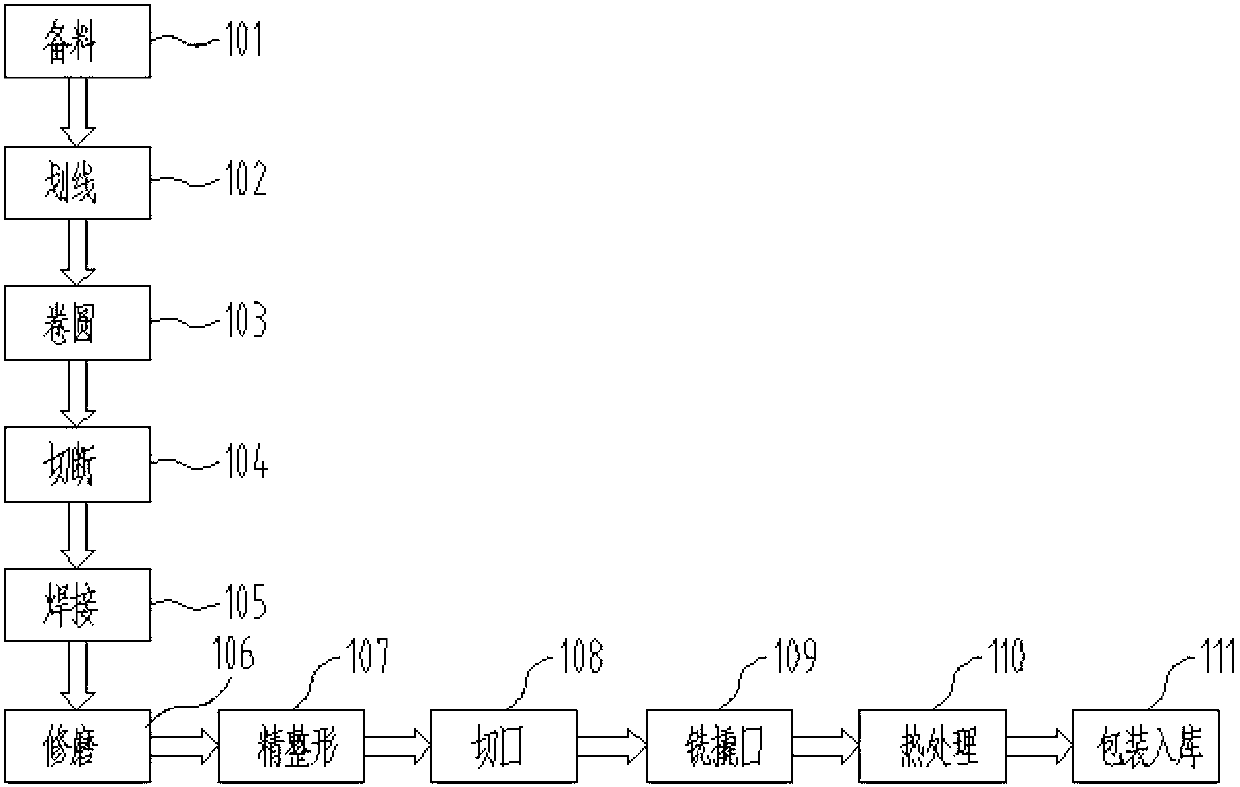

[0040] Such as figure 1 As shown, the embodiment of the multi-piece small engineering wheel lock ring manufacturing process provided by the invention comprises the following operations:

[0041] S101 Material preparation Rolling the steel billet into strips with the cross-sectional structural shape of the prefabricated lock ring;

[0042] S102 Scribing Lines Use a special sizing rod to draw lines on the strip section steel, starting at a distance of 100mm from its end, according to the length of the single-scale ring material;

[0043] S103 Rolling Use a rolling machine to make strip-shaped steel coils into spiral coils, and the spiral diameter of the spiral coils is roughly the same as the diameter of the prefabricated lock ring;

[0044] S104 Cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com