Rotating shaft key groove machining method

A processing method and keyway technology, which is applied in the field of electric transmission system, can solve the problems of large tool wear, easily out-of-tolerance keyway size, poor surface roughness of keyway, etc., and achieve the effects of improving service life, ensuring processing quality and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

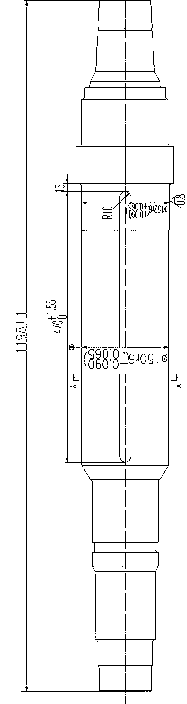

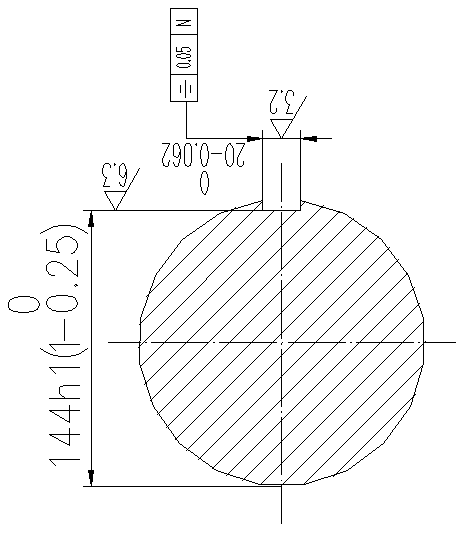

[0016] A method for processing a shaft keyway is as follows:

[0017] 1. Fine grinding the outer circle of the shaft journal.

[0018] 2. Place the rotating shaft on the vertical milling machine and support it to the journal level with a V-shaped block and adjust it to be parallel to the machine table and press it tightly.

[0019] 3. Mark the line to determine the processing length of the keyway.

[0020] 4. Correct the center of the machine tool spindle to be consistent with the center of the rotating shaft.

[0021] 5. Drill a flat-bottomed technical hole at one end of the keyway with a Φ19 twist flat-bottomed drill bit, with a depth of 5.8mm.

[0022] 6. Use a high-speed steel vertical milling cutter with a diameter of Φ19.8, and enter the process hole through the process hole to rough-mill the keyway. The size of the key is 19.8mm wide and 5.8mm deep. Speed V=20mm / min.

[0023] 7. Clean up the machined iron filings in the keyway.

[0024] 8. Use Φ20-0.03 double-edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com