Horizontal feeding mechanism for the front conveyor belt for punching bearing blanks

A technology of conveyor belt and blank, applied in the field of mechanical bar material conveying structure, can solve the problems of small focus point, small entry point, long feeding rod, etc., and achieve the effect of compact and reasonable structure and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

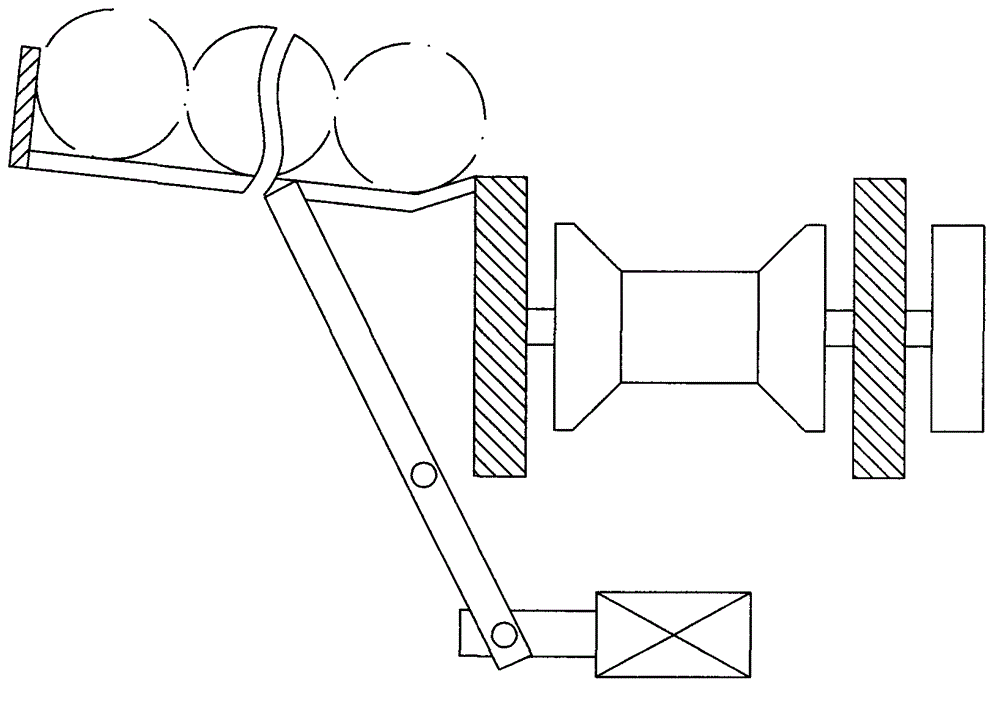

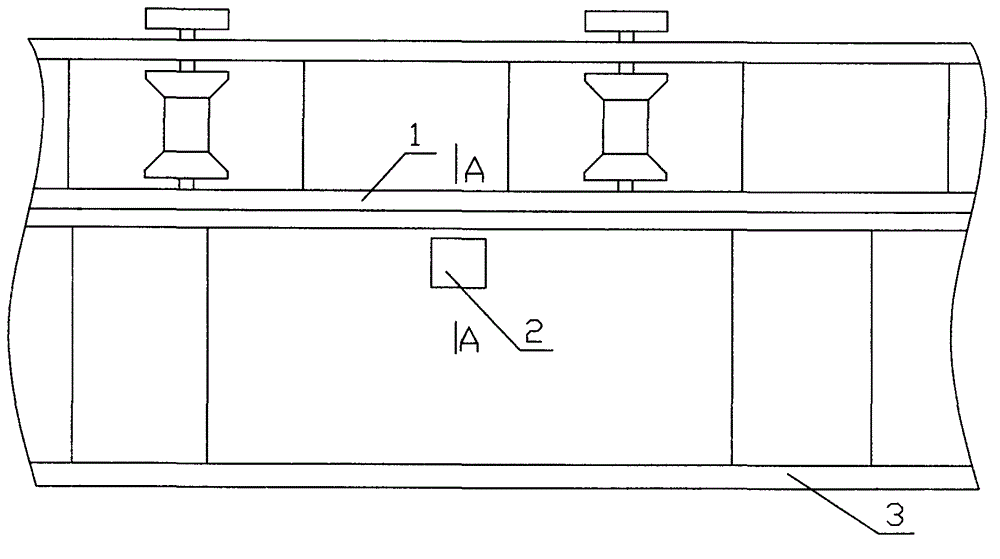

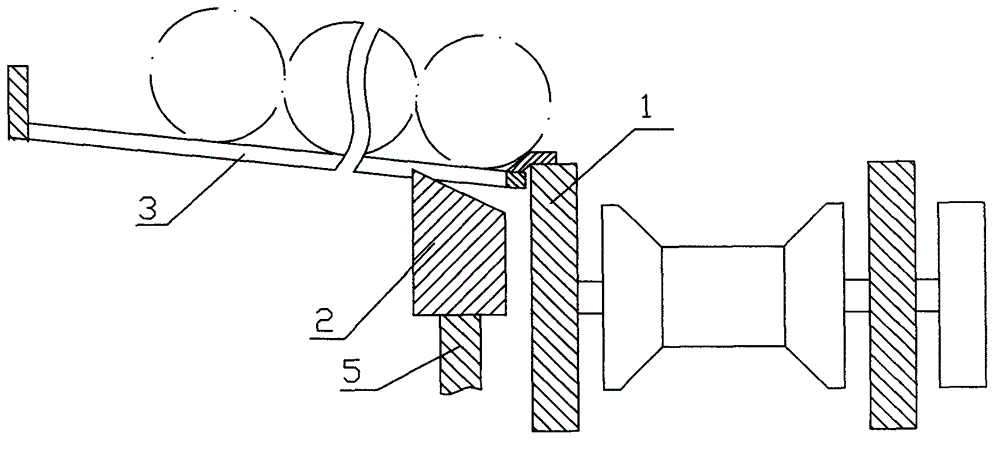

[0011] The structure of the present invention comprises feeding frame 3, cylinder 11, is characterized in that: the long steel plate wall 1 outer side of conveyer belt is provided with longitudinal bracket parallelly, and the two ends of longitudinal beam 7 of longitudinal bracket respectively fix a short square tube cover 6, short square tube cover 6. A square tubular elevating rod 5 is fitted in the internal movement. The upper end of the elevating rod 5 is fixed with a push rod block 2 with a lateral width smaller than the diameter of the bar material. There is a U-shaped fork with an opening downward, and a pin shaft is fixed in the center holes on both sides of the U-shaped fork, and the pin shaft is moved up to fit the pulley 8; the center point of the longitudinal beam 7 is fixed to a cylinder 11 downward, and a cylinder 11 is fixed on the end of the piston. The transverse plate 13 is symmetrically provided with two through holes on the transverse plate 13, and the longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com