Automatic-moving-type stepping machine tail device

A self-moving, belt conveyor technology, applied in the directions of transportation and packaging, earth-moving drilling, underground transportation, etc., can solve the problems of affecting safety and work efficiency, large pushing resistance, and sliding shoes gnawing at the bottom, etc., and achieves a simple structure, The effect of reducing push resistance and improving stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

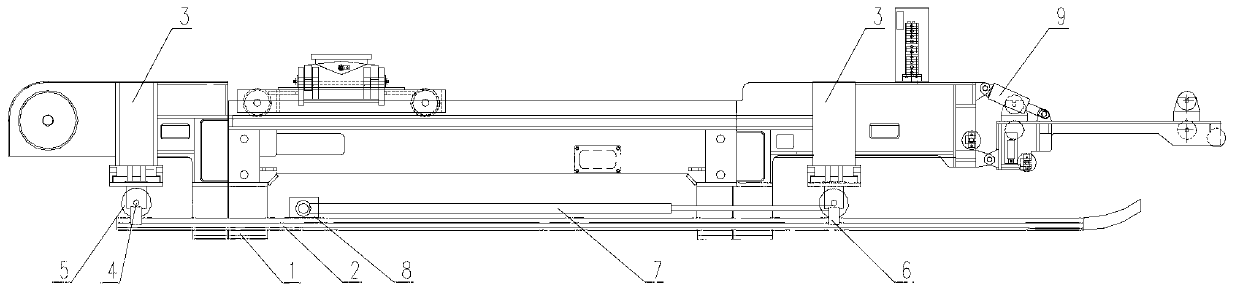

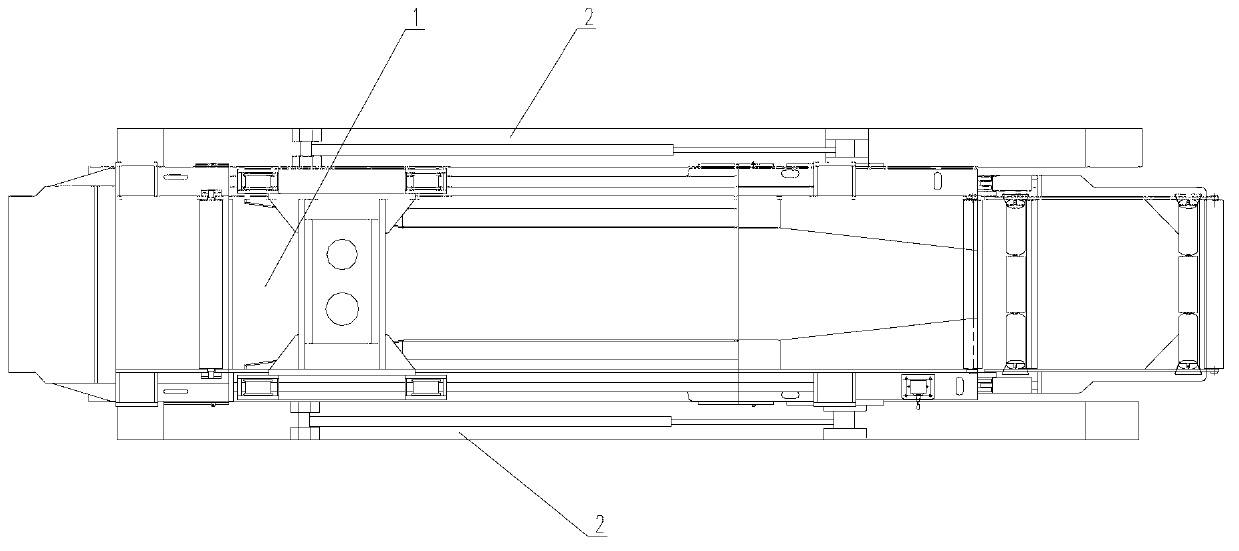

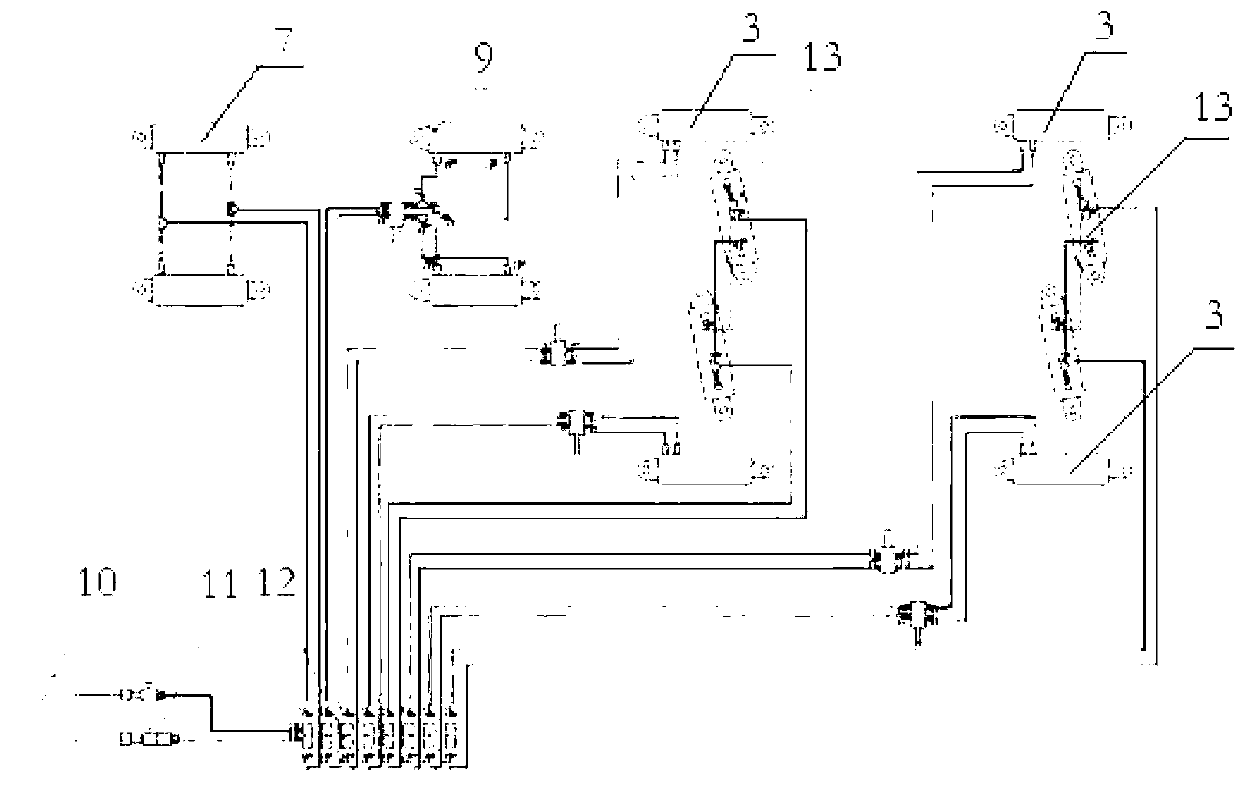

[0021] see figure 1 and figure 2 , a stepping self-moving tail device provided by the present invention is installed at the tail 1 of the belt conveyor, including guide rails 2 arranged on both sides of the tail 1 of the belt conveyor along the direction of the belt, above the guide rail 2 there is an inverted The lifting cylinder 3 on the tail 1 of the belt conveyor, the extended end of the piston rod of the lifting cylinder 3 is connected with the roller 5 that can roll along the guide rail 2 through the roller shaft 4, and the roller 5 is connected and installed with the guide rail 2 There is an anti-climbing hook 6; the top of the guide rail 2 is also horizontally provided with a push cylinder 7, the piston rod end of the push cylinder 7 is connected to the roller shaft 4 on one side, and the other end is connected to the push cylinder fixed on the guide rail 2 On the support 8; the lifting cylinder 3 and the pushing cylinder 7 are both connected with the hydraulic contr...

Embodiment 2

[0023] Present embodiment is the operating process of the present invention:

[0024] The first step is to lift the oil cylinder 3 to work, the piston rod is stretched out to make the guide rail 2 land and further support the entire belt conveyor tail 1; the second step is to push the oil cylinder 7 to work, the belt conveyor tail 1 moves forward as a whole, and the tail passes through The rolling of the roller 5 on the guide rail 2 realizes the smooth forward movement; the third step, after reaching the preset position, lift the oil cylinder 3 to retract the piston rod, and the anti-climbing hook 6 also lifts the guide rail 2 to break away from the contact with the ground. When the tail 1 of the belt conveyor is in contact with the ground, the tail can work stably; the fourth step is to push the oil cylinder 7 to work, adjust the oil inlet direction to make the cylinder move in the forward direction, and drive the guide rail 2 to move in the forward direction, for the next Mo...

Embodiment 3

[0027] see figure 1 , the tail 1 of the belt conveyor is provided with an angle adjustment oil cylinder 9 for adjusting the angle of the idler roller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com