Compound convection dryer

A convection dryer and dryer technology, applied in drying solid materials, drying gas arrangement, drying and other directions, can solve problems such as adverse effects of energy saving and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with accompanying drawing and embodiment the utility model is described further

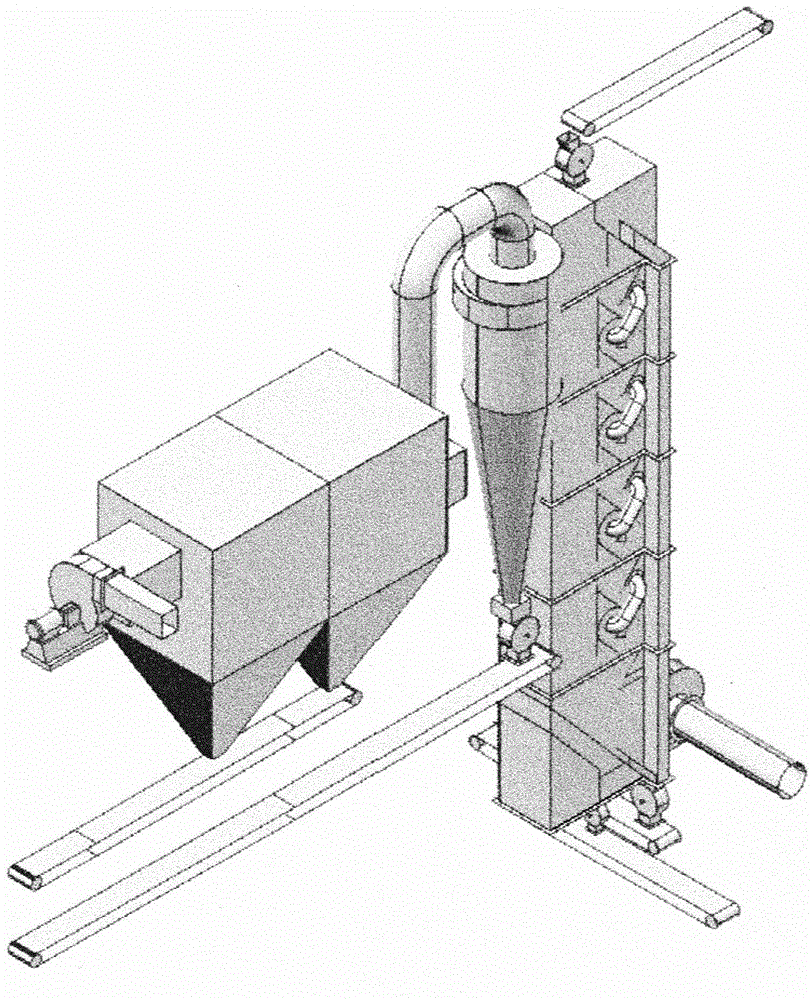

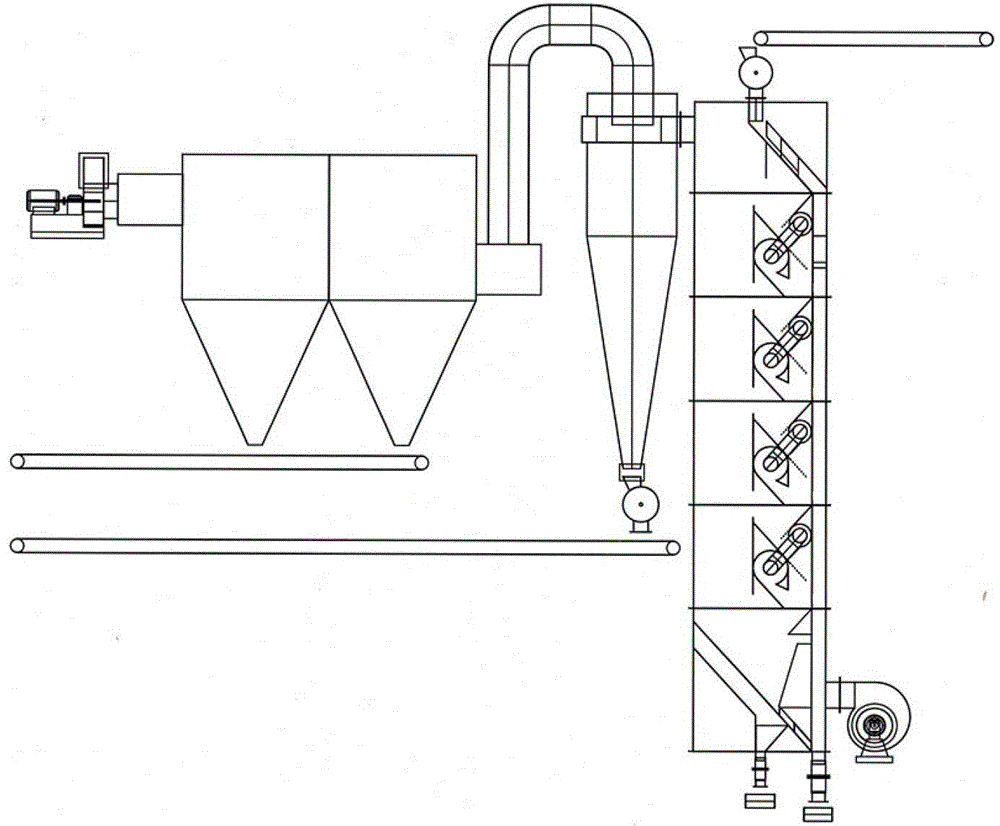

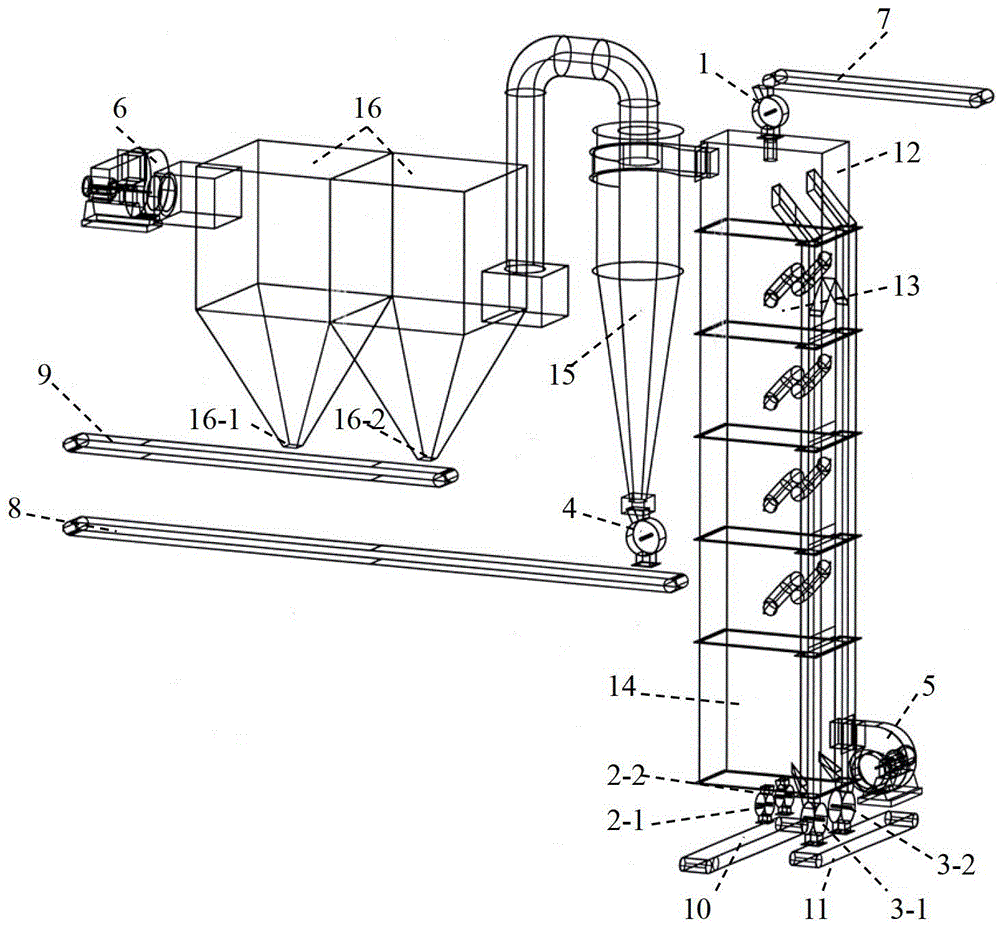

[0052] Figure 1 to Figure 16 An embodiment of the compound convection dryer proposed by the present invention is given, which is an embodiment with four stages of dryers.

[0053] Comprising a coarse separator unit 12, a dryer unit 13 and a coal dust separator unit 14, the coarse separator unit 12 includes a coarse separator housing 17 and an internal mechanism of the coarse separator, and the left and right sides of the front end of the coarse separator housing 17 are respectively provided with Coarse classifier left coarse-grained coal export tank 21-1 and coarse classifier right coarse-grained coal export tank 21-2, the coarse classifier left coarse-grained coal export tank on the bottom surface of the coarse classifier shell 17 Between 21-1 and the right coarse-grained coal material outlet groove 21-2 of the coarse separator is the downward outlet 22 of the mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com