Test machine for testing aligning torque of manually operated recliner of automobile seat

A technology of car seats and recliners, which is applied in the direction of instruments, measuring devices, torque measurement, etc., can solve problems such as the test of the return torque of recliners that are not applicable, and achieve convenient testing, accurate test results, and structural design simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

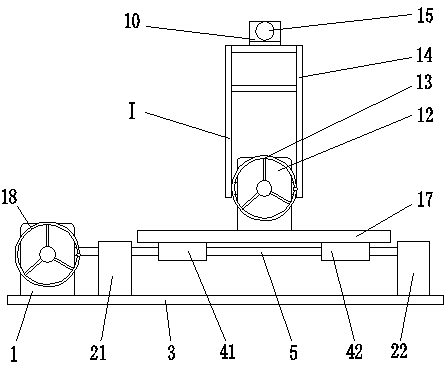

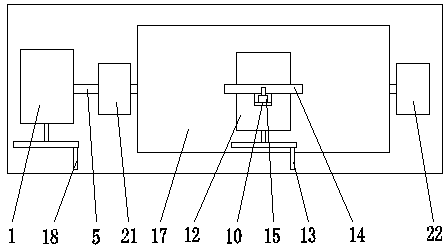

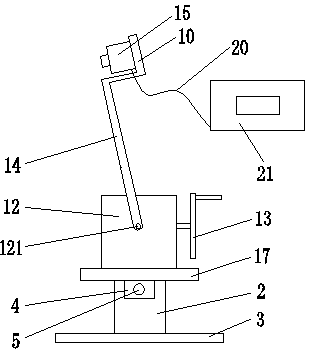

[0021] see figure 1 — Image 6 , the embodiment of the present invention is mainly composed of interconnected test device I and skeleton device II; test device I includes a lower worm gear box 1, a lower worm gear box hand wheel 18, a rotating seat 2, a bottom plate 3, a rotating fixed block 4, and a rotating shaft 5. Sensor mounting plate 10, upper worm gear box 12, upper worm gear box rotating hand wheel 13, sensor rotating skeleton 14, force sensor 15, fixing plate 17, sensor display 21 and angle automatic measuring instrument 22; skeleton device II includes angle adjustment Adjuster mounting base base plate 6, recliner mounting base 7, recliner lower plate 8, recliner upper plate 9, simulated skeleton sensor force plate 11 and simulated backrest skeleton 16.

[0022] The lower worm gear box 1 and the rotating seat 2 in the test device I of the present invention are fixed on the bottom plate 3, the rotating shaft 5 is connected with the lower worm gear box 1, the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com