Ventilated Disc Brake Electric Inertia Simulation Test Bench and Its Electric Inertia Simulation Control Method

A technology for simulating control and braking, which is used in the testing of machine/structural components, instruments, measuring devices, etc., and can solve problems such as affecting the test accuracy and generating the inherent resistance torque of the system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

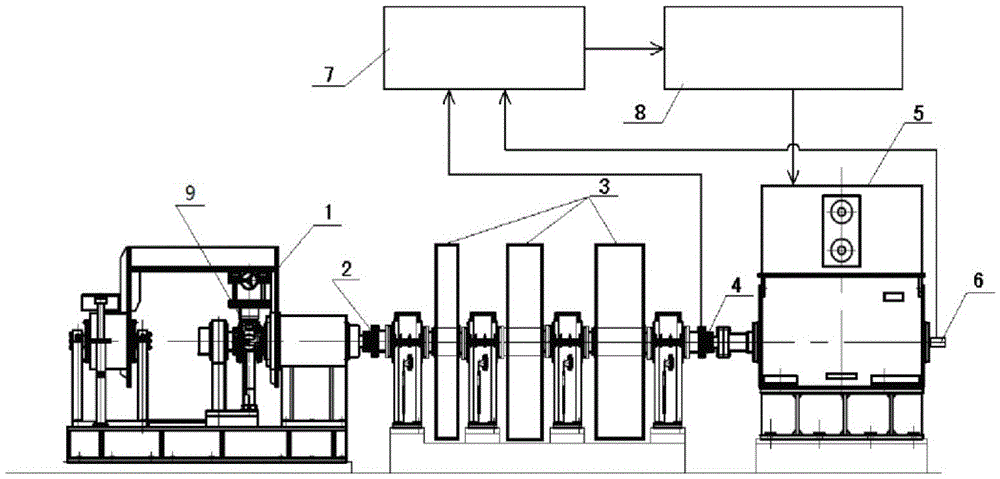

[0074] Such as figure 1 As shown, a ventilated disc brake test bench electric inertia simulation control device is characterized in that it at least includes a mechanical friction braking torque measuring device 1, a combined braking torque sensor 2, a flywheel or flywheel group 3, a motor output torque sensor 4, Drive motor 5, speed sensor 6, electric inertia analog control unit 7 and electric transmission control unit 8, motor output torque sensor 4 is installed between drive motor 5 and flywheel group 3, and speed sensor 6 is installed at the shaft end. A combined braking torque sensor 2 is installed between the brake 9 and the flywheel or flywheel group 3, a mechanical friction braking torque measuring device 1 is installed on the tested brake 9, a speed measuring sensor 6, and a motor output torque sensor 4 are respectively connected with the electrical inertia analog control The unit 7 is electrically connected, and the electric transmission control unit 8 drives the dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com