Mechanical and electric inertia simulation tire braking bench and electric inertia simulation control method

A technology of braking test and simulation control, applied in the field of electric inertia simulation control, with mechanical and electric inertia simulation tire braking test bench, which can solve the problems affecting the test accuracy and generating the inherent resistance torque of the system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

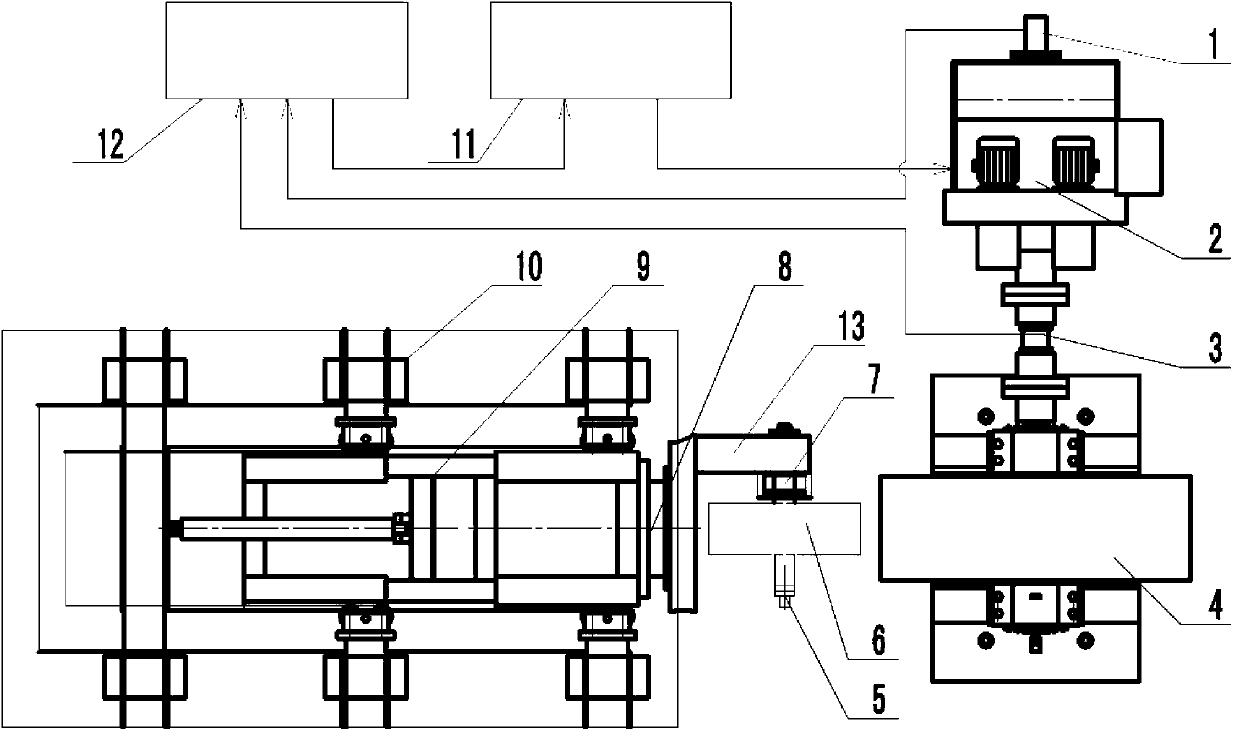

[0063] Such as figure 1 As shown, the mechanical and electrical inertia simulation tire brake test bench is characterized in that it includes at least a speed sensor 1, a drive motor 2, a torque sensor 3, a drum device 4, a tire speed sensor 5, a test tire and a brake 6, Mechanical friction braking torque measuring device 7, load cell 8, movable frame 9, fixed frame 10, electric transmission control unit 11 and electric inertia simulation control unit 12; The torque sensor 3 is used to measure the output torque of the motor, the shaft end is equipped with a speed sensor 1 for measuring the rotating speed of the motor and the drum, and a mechanical friction braking torque measuring device 7 is installed between the tested tire and the brake 6 and the machine head 13. To measure the mechanical friction moment of the brake, a load cell 8 is installed between the head 13 and the movable frame 9 to measure the loading force acting on the tire. The movable frame 9 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com