Method of detecting glass defects based on phase image processing

A glass defect and phase image technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as poor anti-interference ability, slow deployment speed, unsuitable for real-time glass defect detection, etc., to achieve elimination Effect of background noise, accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

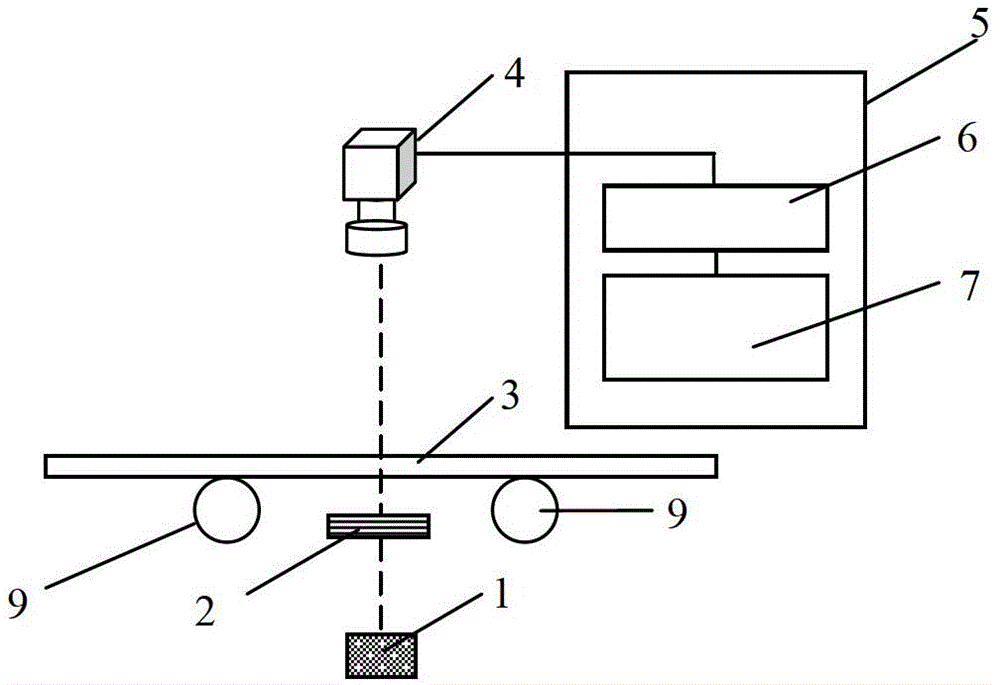

[0028] Introduce detailed technical scheme of the present invention below in conjunction with accompanying drawing:

[0029] Such as figure 1 As shown, the glass defect detection system based on phase image processing includes light source 1, transmission grating 2, high-speed line scan camera 4 (CCD), image acquisition card 6, industrial computer 7, control cabinet 5, roller 9 and defect detection processing software , the light source 1 is a strip-shaped LED light source, located under the glass 3 to be tested, the transmission grating 2 is located between the glass 3 to be tested and the light source 1, and is close to the lower surface of the glass 3 to be tested; the high-speed linear array CCD camera 4 is placed on the Above the glass 3, the scanning line of the high-speed linear array camera 4, the center line of the transmission grating 2 and the light source 1 are on the same vertical plane; Move at a constant speed; the image acquisition card 6 is inserted into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com