Solar cell module without welding strips and preparation method thereof

A technology for solar cell modules and solderless ribbons, which is applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of loss, complex structure and preparation process, expensive materials used, etc., and achieves high production capacity and simple preparation method. Reliable, low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The term "upper" in the claims, description and drawings of the description refers to the light-receiving side of the solar cell module unless otherwise specified.

[0017] The present invention will be further described below in conjunction with the figures.

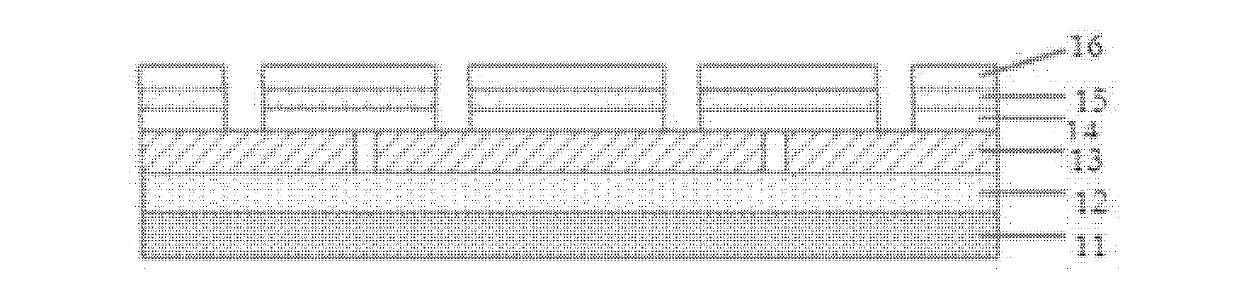

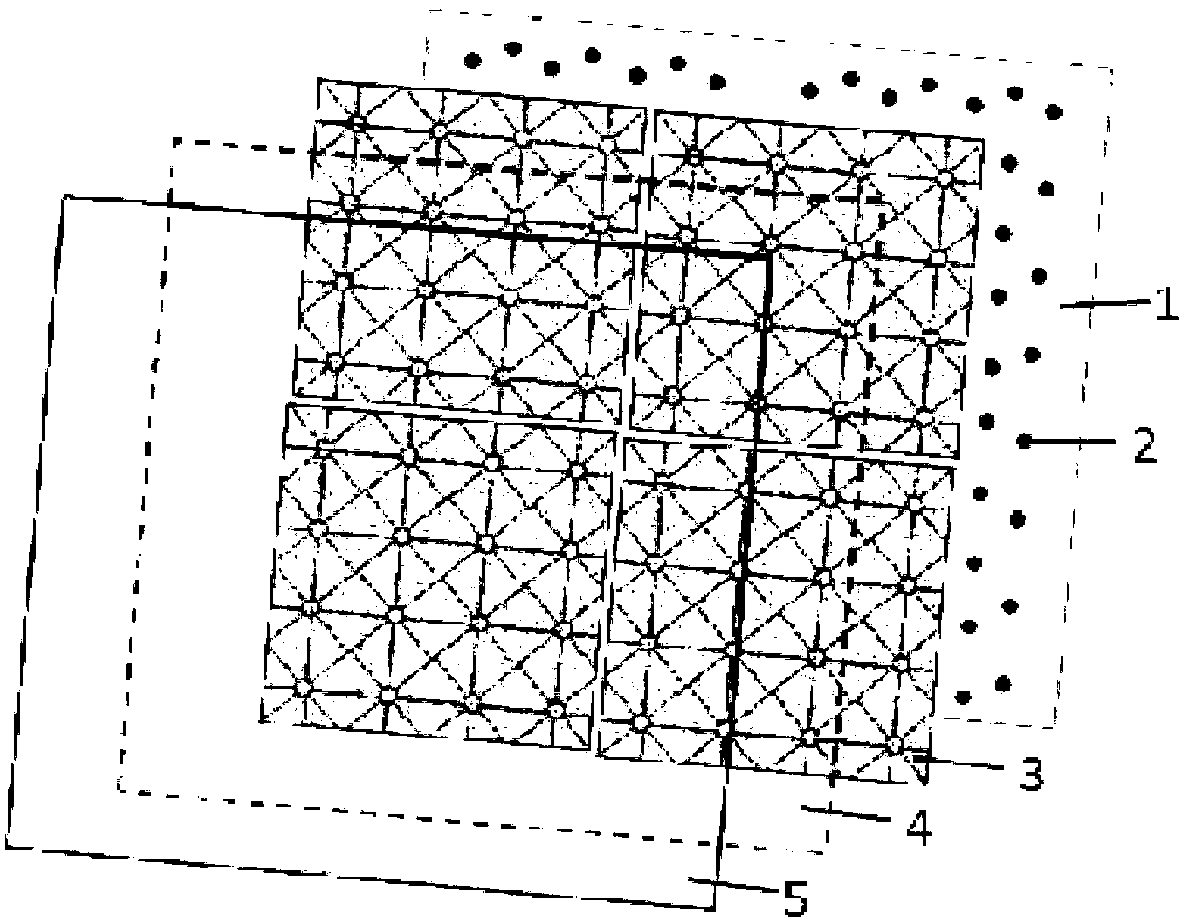

[0018] Such as figure 1 and figure 2 As shown, the solar cell module of the present invention is composed of five layers, and the conductive backplane 1, the conductive adhesive connection point 2, the back contact cell sheet 3, the packaging material 4 and the tempered glass 5 are stacked together from bottom to top; The preparation method of the battery assembly is to print conductive glue on the conductive backplane 1 by dispensing or steel plate printing, and the position of the printed conductive glue matches the position of the electrode point of the back contact battery sheet 3 to form a conductive glue connection point 2, The curing temperature of conductive glue is 80 to 140°C. The material of conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com