A method of manufacturing a carrier board

A manufacturing method and carrier board technology, which are used in chemical/electrolytic methods to remove conductive materials, multi-layer circuit manufacturing, circuit substrate materials, etc. Small thermal expansion coefficient and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with examples and accompanying drawings.

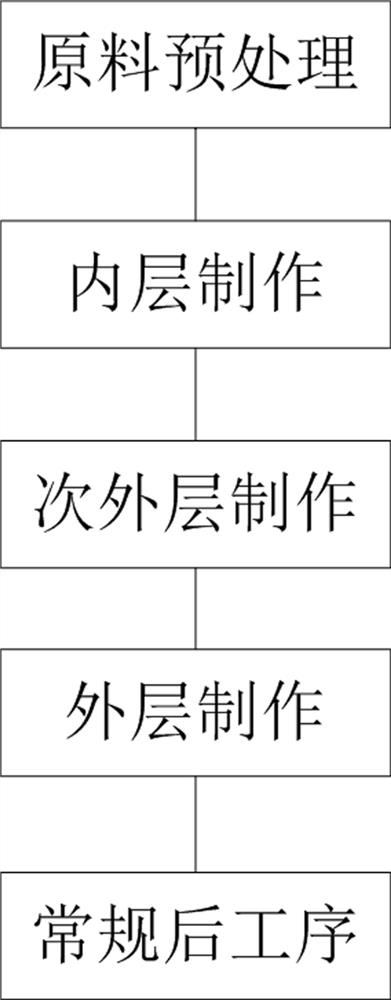

[0027] Such as figure 1 As shown, a manufacturing method of a kind of carrier board includes the following steps,

[0028] The first step is raw material pretreatment. First, the core board is made of BT material, and the upper and lower surfaces of the core board are

[0029] Coated with a copper layer to make the core board form a copper-clad BT core board, then cut the copper-clad BT core board according to the required size, and clean the board surface of the cut copper-clad BT core board;

[0030] The second step is the production of the inner layer. The inner layer production includes sequentially performing copper reduction, browning, laser blind holes, glue removal, hole metallization, hole filling electroplating, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com