Three-position solid insulation switchgear

A solid insulated switch, three-position technology, applied in the setting of switchgear with a resin shell, etc., can solve the problem of insulation breakdown, inability to completely ensure that there is no leak point, and three working positions of the switch cabinet that cannot be seen and other issues to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

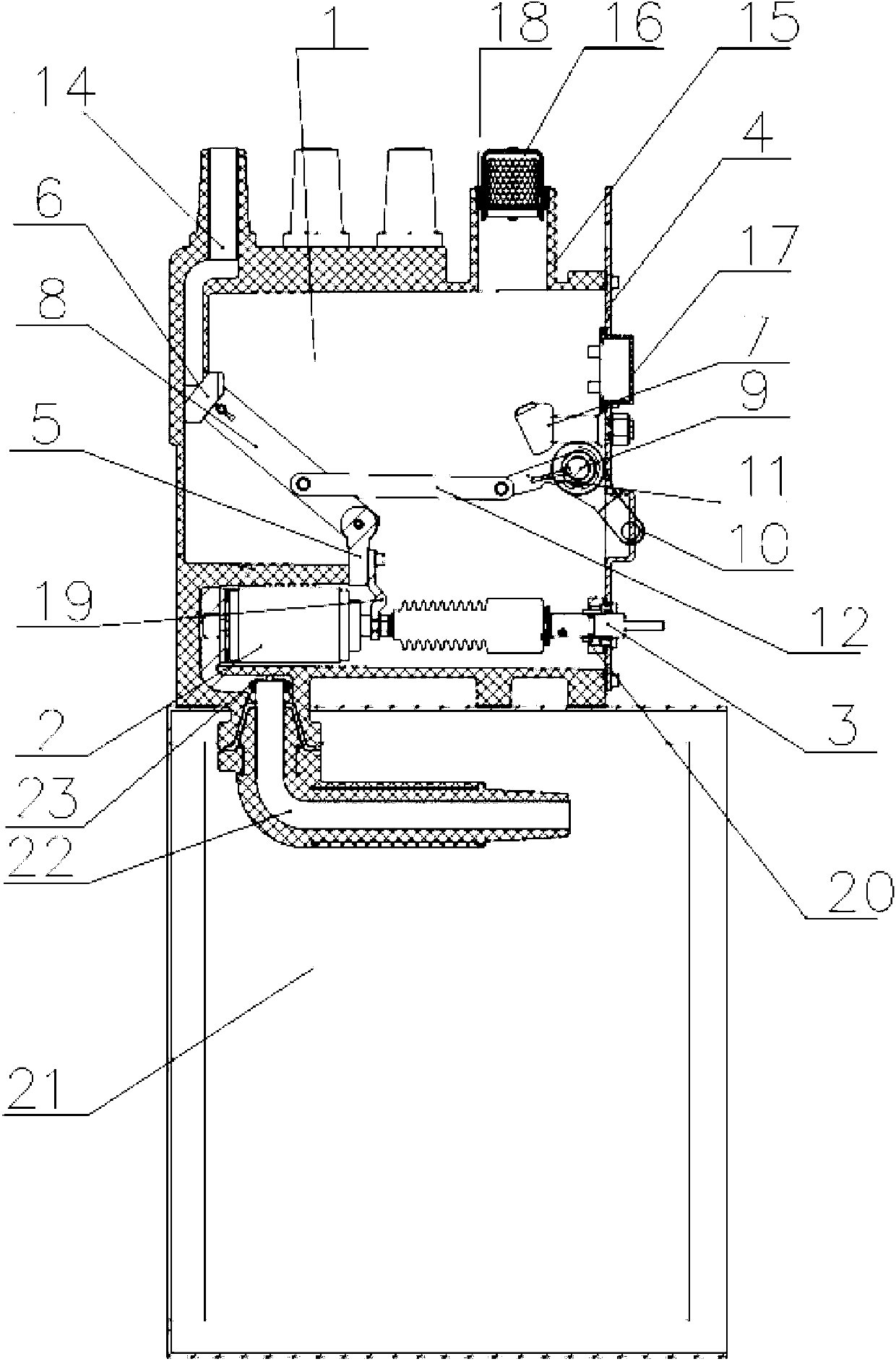

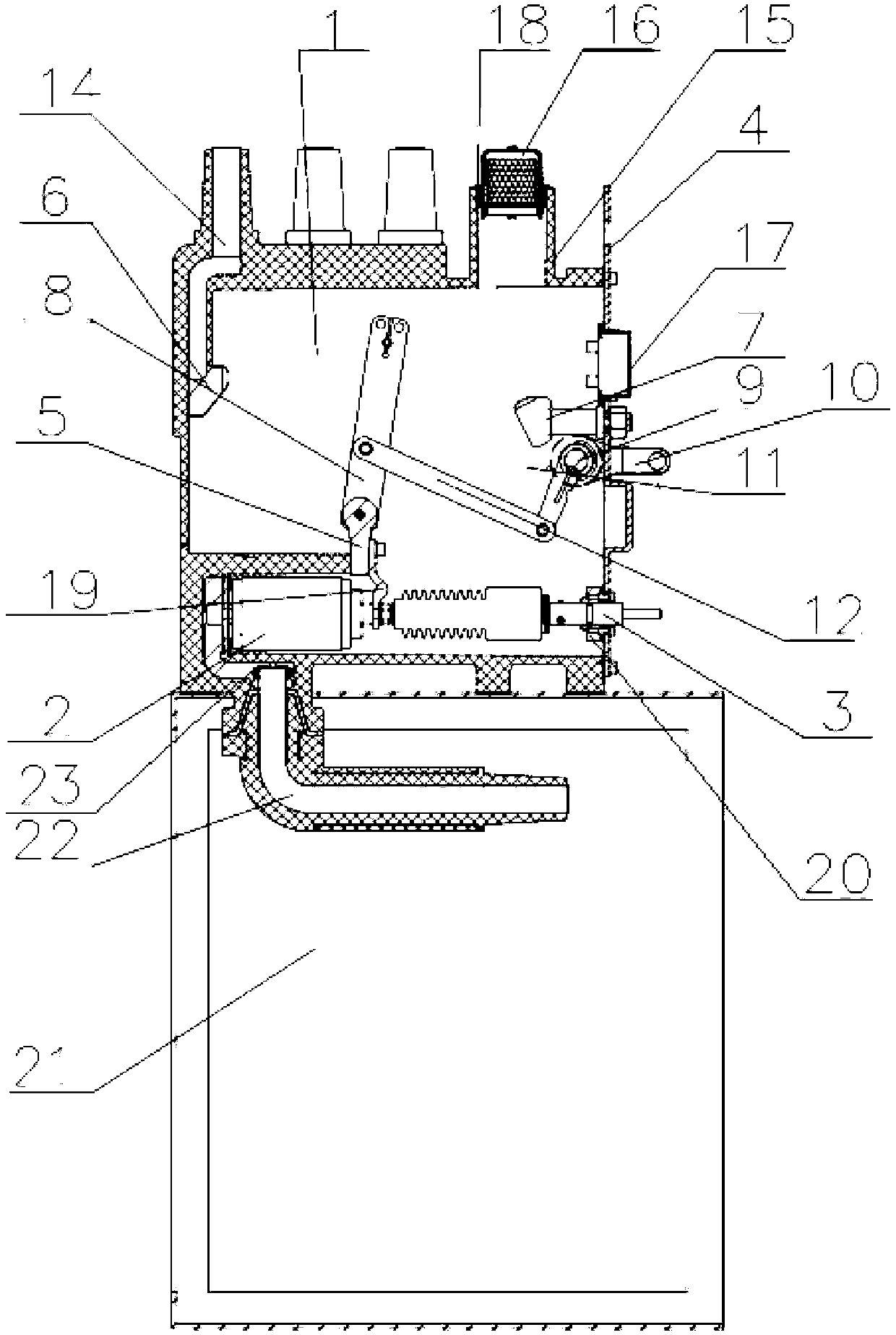

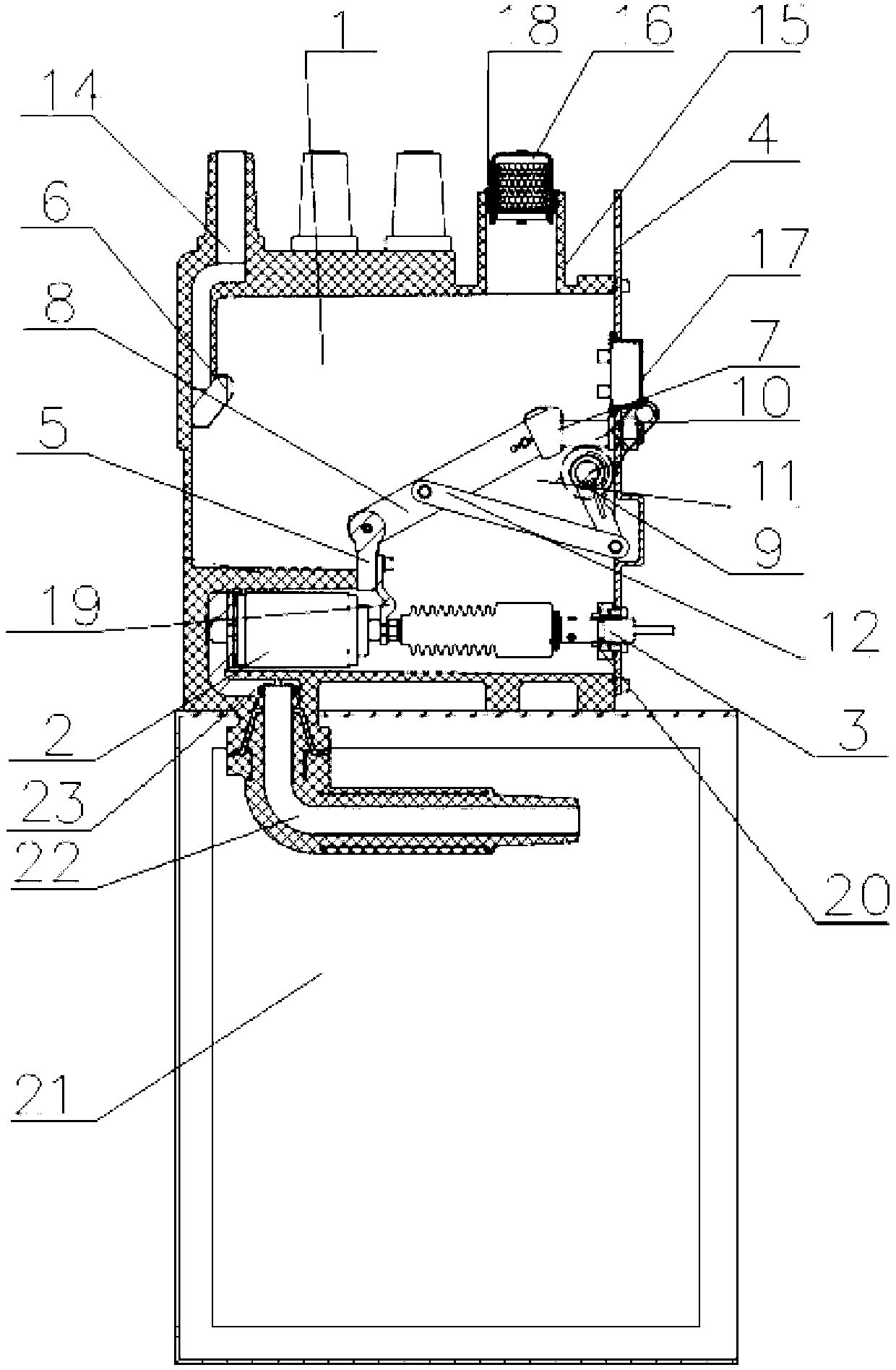

[0030] Please see figure 1 , figure 2 and image 3 As shown, the three-position solid insulated switchgear of the present invention includes A-phase main circuit box body, B-phase main circuit box body and C-phase main circuit box body assembled together side by side, A-phase main circuit box body, B-phase main circuit box body The box body and the C-phase main circuit box body respectively include an insulating shell 1 , an isolation knife 8 , a contact seat 5 , a grounding static contact 7 , a packaging cover plate 4 , and an input terminal 14 and an output terminal 23 .

[0031] The vacuum interrupter 2 and the static contact 6 are solidly sealed in the insulating case 1. The movable end of the vacuum interrupter 2 is connected to the first insulating rod 3. One side of the insulating case...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com