A silicon based mems microphone, a system and a package with the same

A microphone, silicon-based technology, applied in the field of microphones, can solve problems such as easy trapping in microphones, diaphragm damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example )

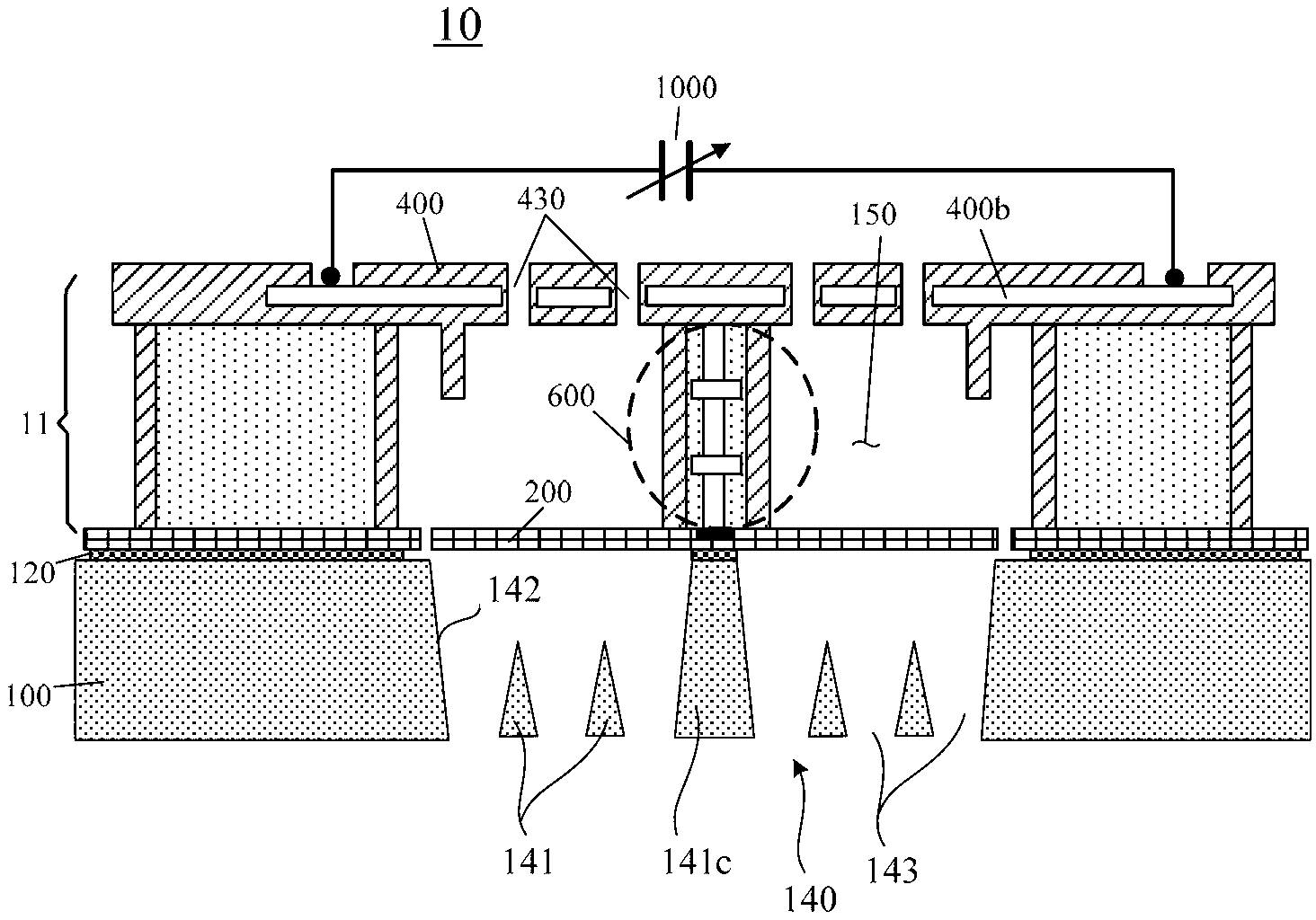

[0032] figure 2 is a sectional view showing the structure of the silicon-based MEMS microphone according to the first embodiment of the present invention. MEMS microphones can receive acoustic signals and convert the received acoustic signals into electrical signals for subsequent processing and output. like figure 2As shown, the silicon-based MEMS microphone 10 described in the first embodiment of the present invention may include a silicon substrate 100 and an acoustic sensing part 11 supported on the silicon substrate 100, wherein, between the silicon substrate 100 and the acoustic sensing part 11 An insulating oxide layer 120 is interposed therebetween. The acoustic sensing part 11 in the microphone 10 may at least include: a conductive and compliant diaphragm 200 , a perforated back plate 400 and an air gap 150 . Diaphragm 200 is formed using a portion of a silicon device layer such as a top silicon film on a silicon-on-insulator (SOI) wafer or using a polysilicon (P...

no. 2 example )

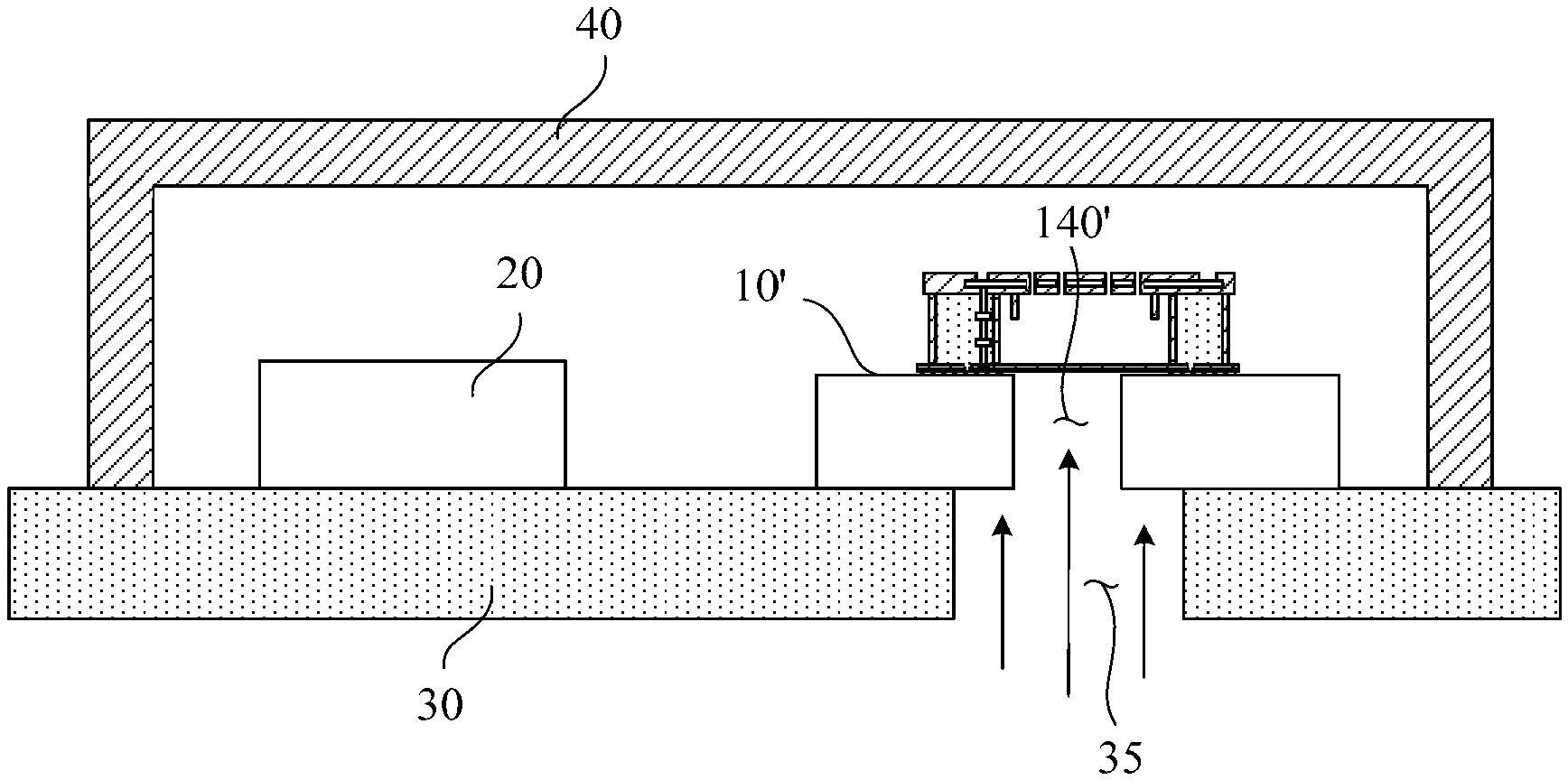

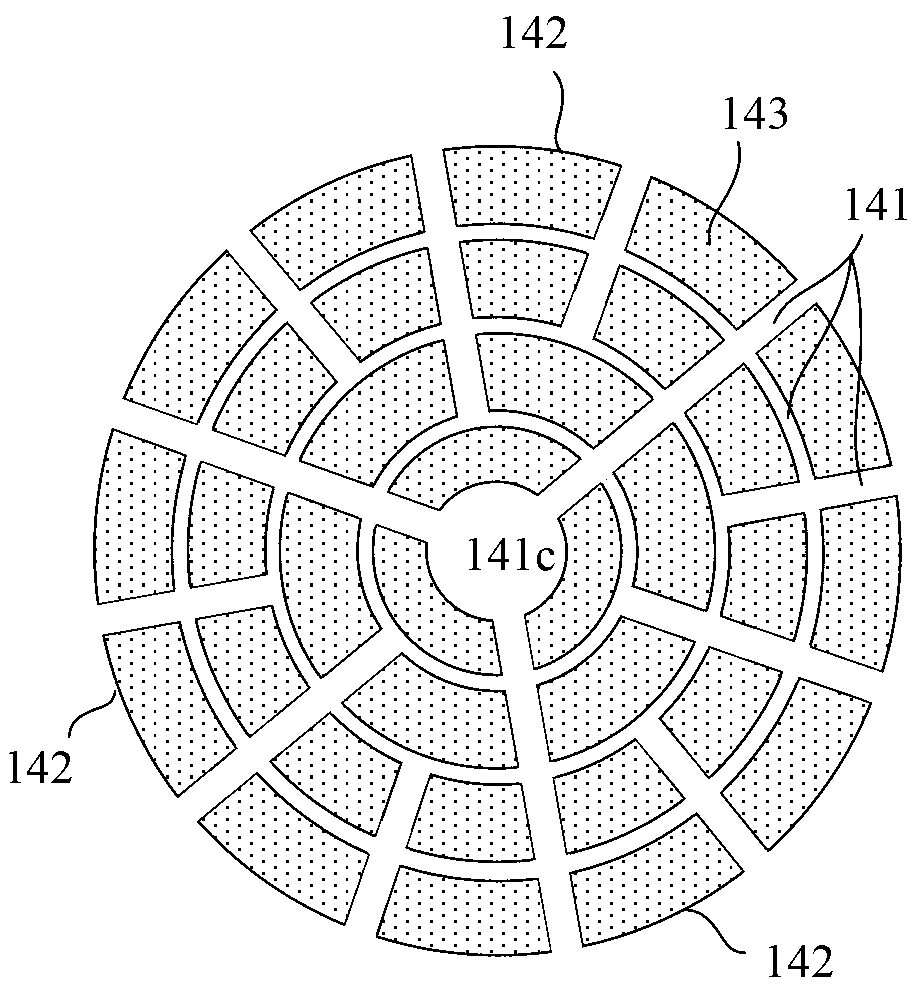

[0039] Image 6 is a cross-sectional view showing the structure of the silicon-based MEMS microphone according to the second embodiment of the present invention, Figure 7 is the floor plan, showing the Image 6 An exemplary pattern of network structure backholes formed in the silicon substrate when viewed from the bottom of the silicon substrate of the microphone in .

[0040] Will Image 6 and figure 2 In contrast, the difference between the acoustic sensing part of the microphone according to the second embodiment of the present invention and the acoustic sensing part of the microphone according to the first embodiment is that, in the second embodiment, the acoustic sensing part of the microphone 10 The sensing part 11 may also include an interconnection column 600, which is arranged between the edge of the diaphragm 200 and the edge of the back plate 400 to electrically lead the diaphragm outward by using a CMOS metal interconnection method, and the diaphragm 200 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com