Improvements to systems for cost-effective concentration and utilization of solar energy

A technology of solar energy and solar cells, applied in the field of improvement of cost-effective solar energy collection and utilization systems, which can solve problems such as insufficient energy sources and misalignment of the entire system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

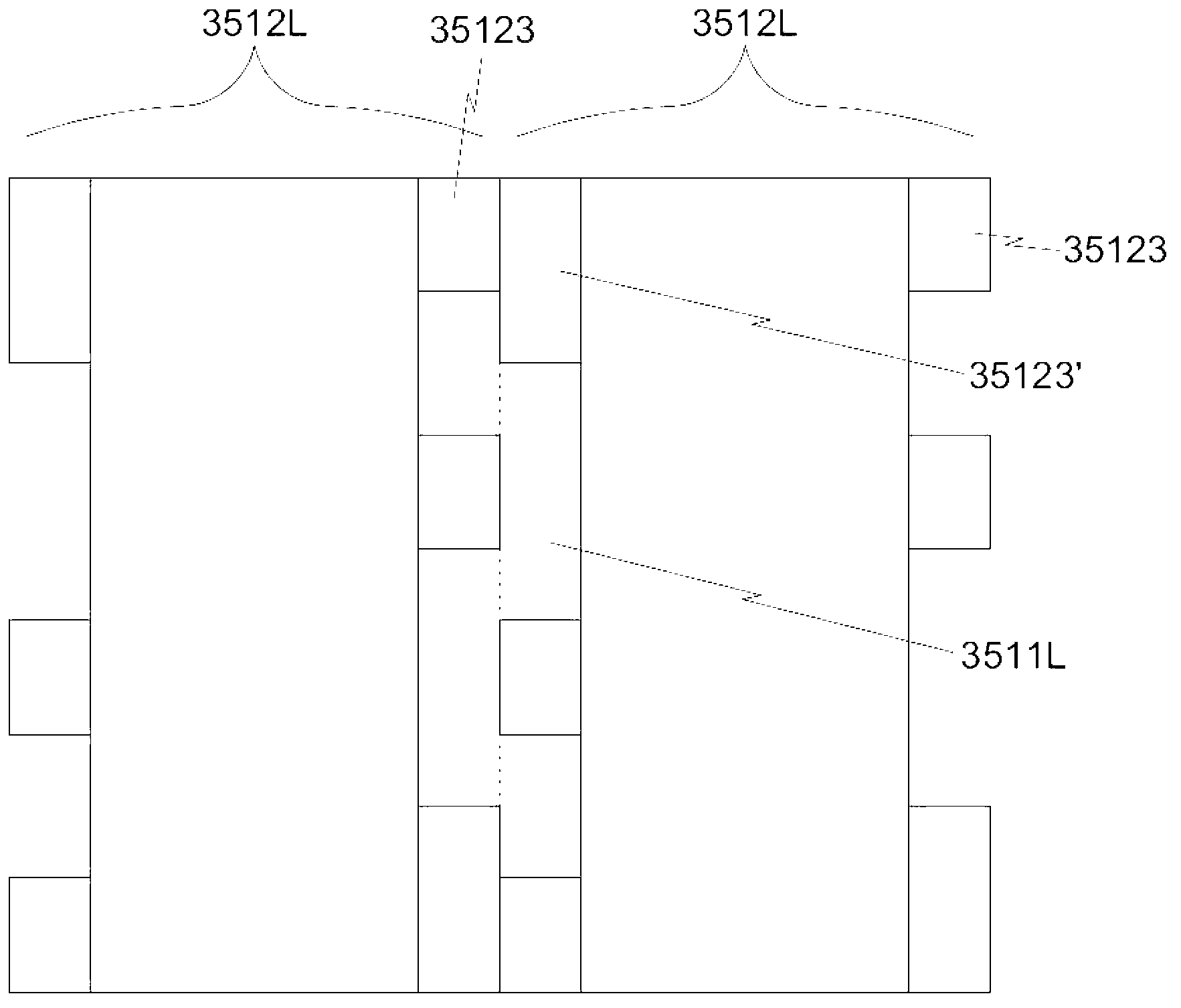

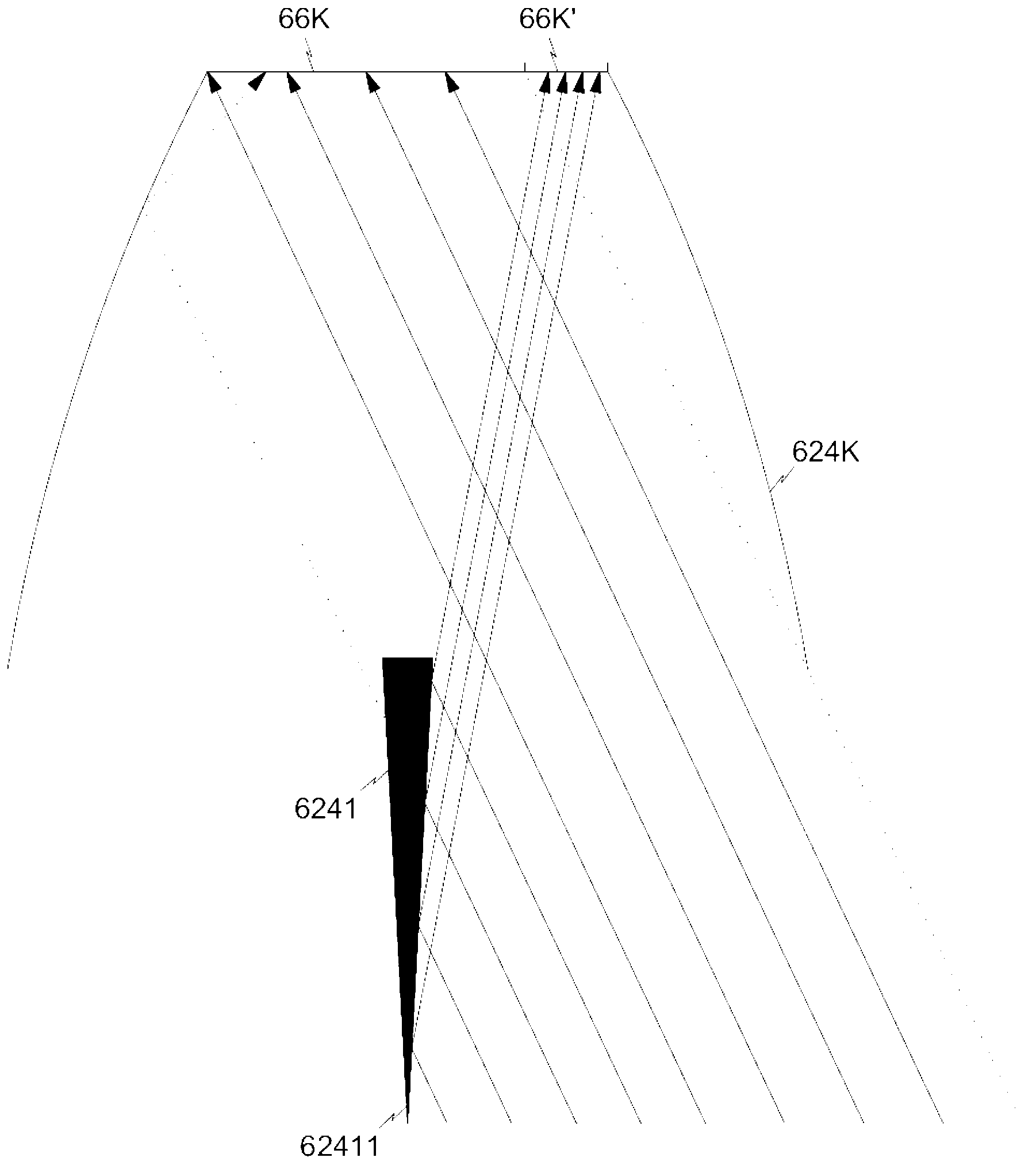

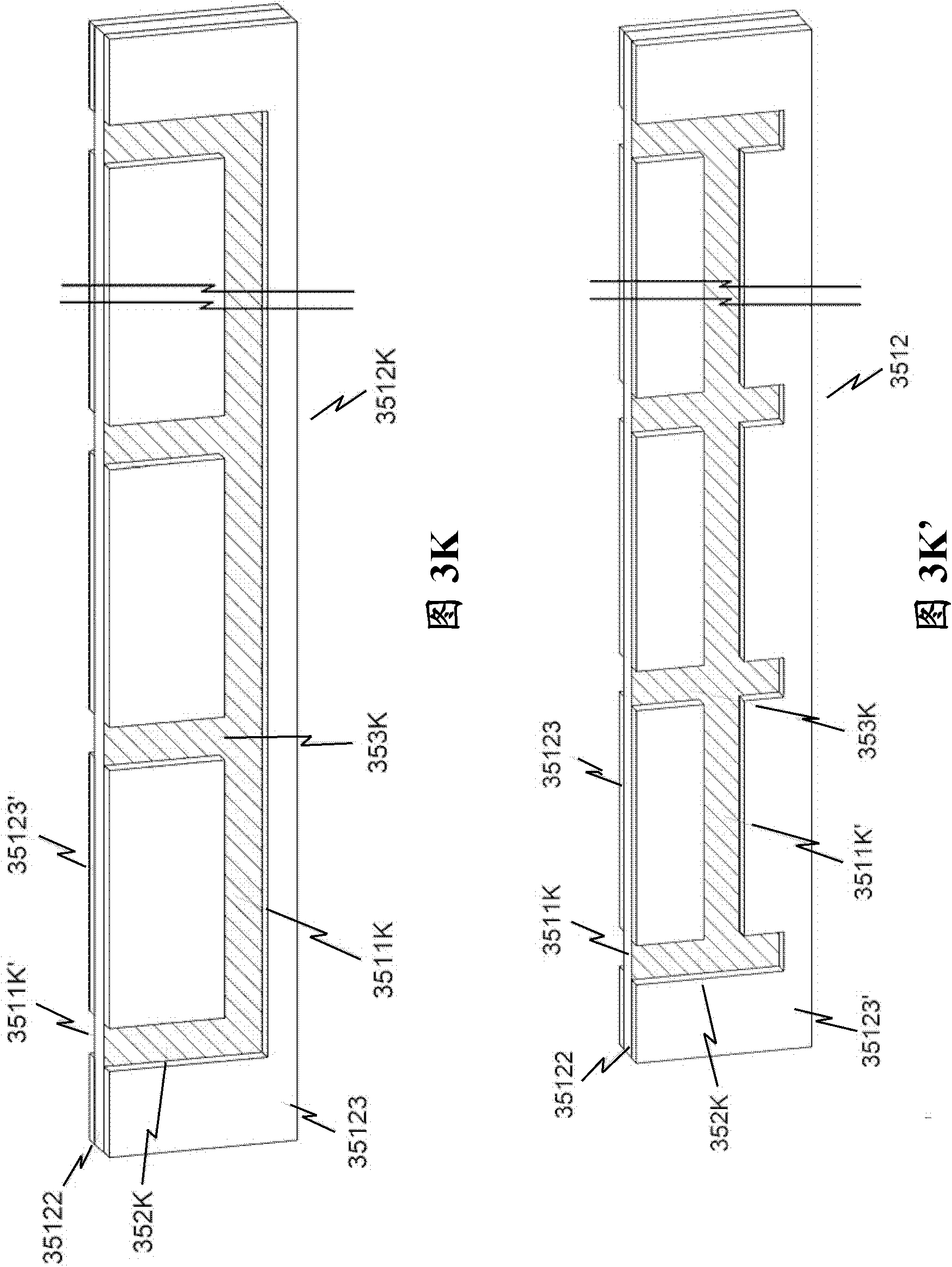

[0430] First set of preferred embodiments: Improved method of manufacturing preformed reflective panels for high concentration solar systems.

[0431] Preformed solar glass mirrors offer the best reflectivity and economy available, the best scratch-resistant mirrors, and the longest practical life. However, preformed solar glass mirrors are currently too expensive.

[0432] Preformed glass parabolic trough structures, typically by pressing a flat glass mirror against a precisely curved and shaped parabolic mandrel, while an adhesive secures the glass to a stable backing material, or preforms a backing material , fix the mirror to the backplane material (Sandwich Constaiction Solar Staictural Facets, Sandia National Labs 1999), or perform compression molding on a precise mandrel to produce glass. When the glass is thin enough and the bending is small enough, cold molding and bonding can be used to achieve combined bending on the glass mirror (US7550054, Lasich), although gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com