Acid mist sedimentation apparatus

A settling device and acid mist technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems such as environmental pollution, corrosion of surrounding equipment, hidden dangers, etc., to improve the factory and surrounding environment, reduce production costs, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

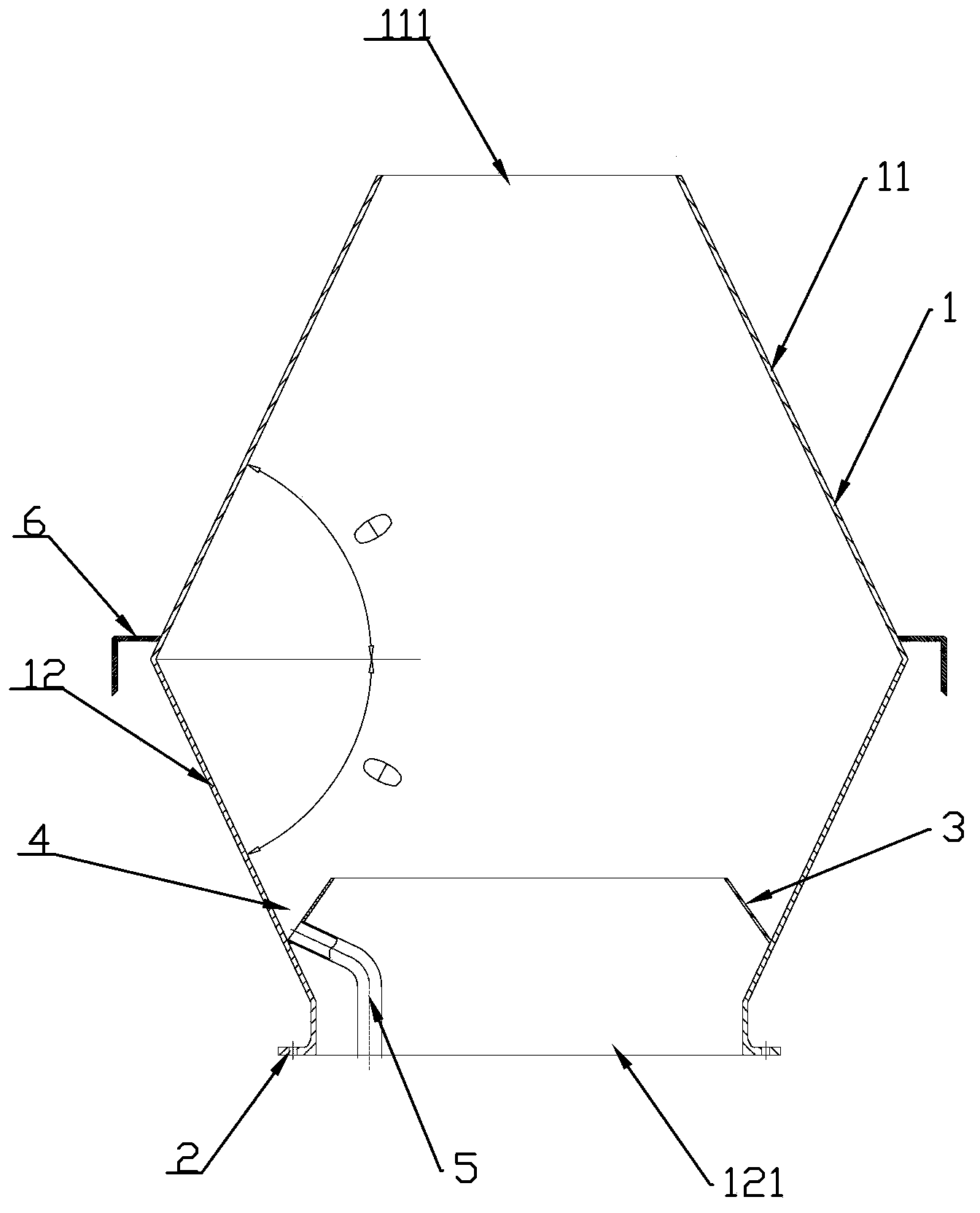

[0014] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0015] Such as figure 1 As shown, an acid mist sedimentation device of the present invention includes a biconical cylindrical shell 1, and the biconical cylindrical shell 1 includes an upper conical cylindrical shell 11 and a lower conical cylindrical shell 12 , the upper end of the upper tapered cylindrical shell 11 is provided with an exhaust port 111, the lower end of the lower tapered cylindrical shell 12 is provided with a connecting port 121, and the connecting port 121 is provided with a connecting flange 2, The inside of the lower tapered cylindrical shell 11 is provided with an annular baffle 3, and the bottom of the annular baffle 3 is fixedly connected with the inner wall of the lower tapered cylindrical shell 12 to form an annular collecting tank 4, the annular collecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com