In-polluted-site heat-intensifying vapor extracting and repairing integrated device and application method

A gas-enhanced, in-situ technology, applied in the restoration of contaminated soil, etc., to achieve the effects of prolonging the effective working time, easy disassembly and assembly, and economical and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

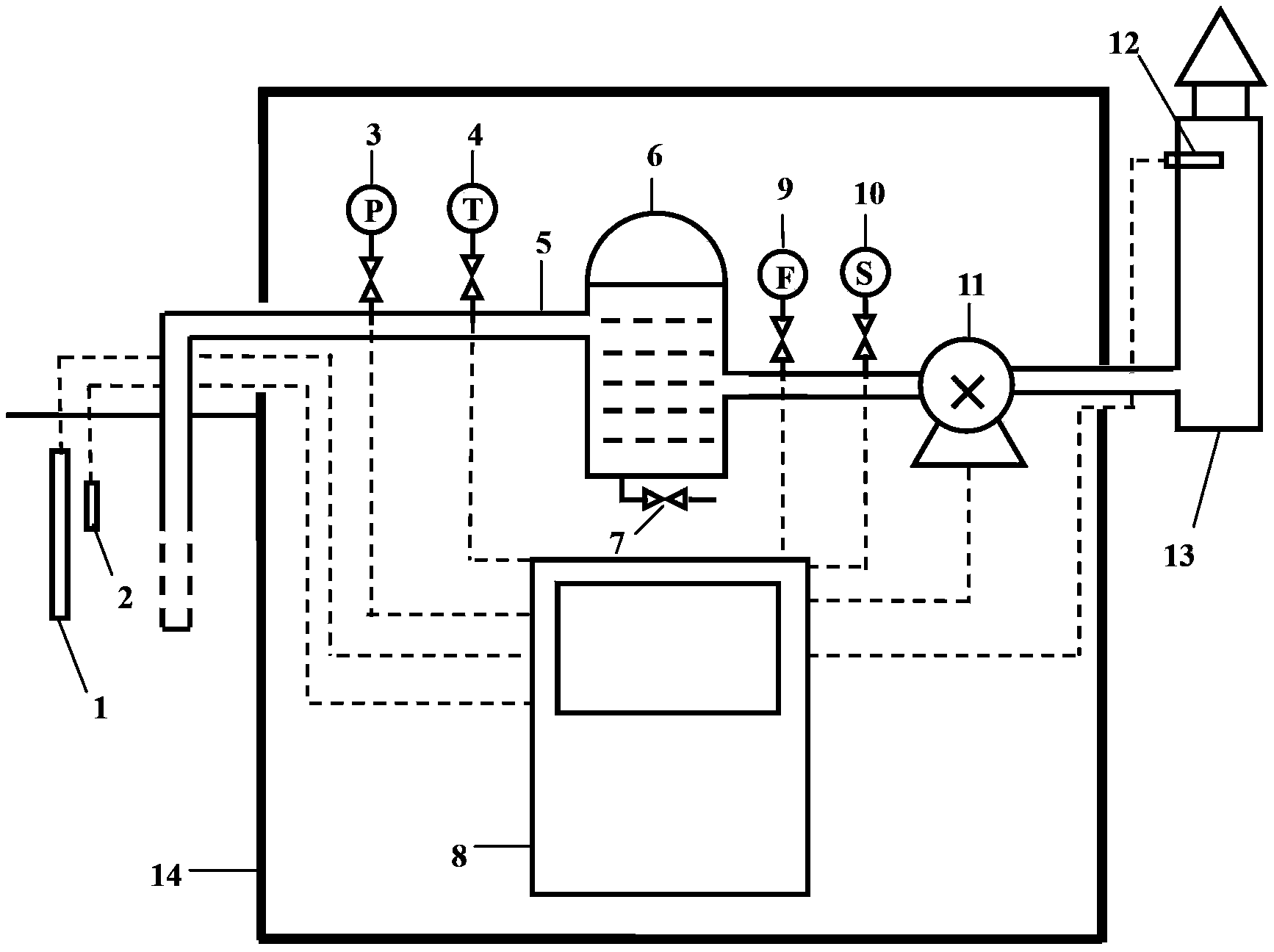

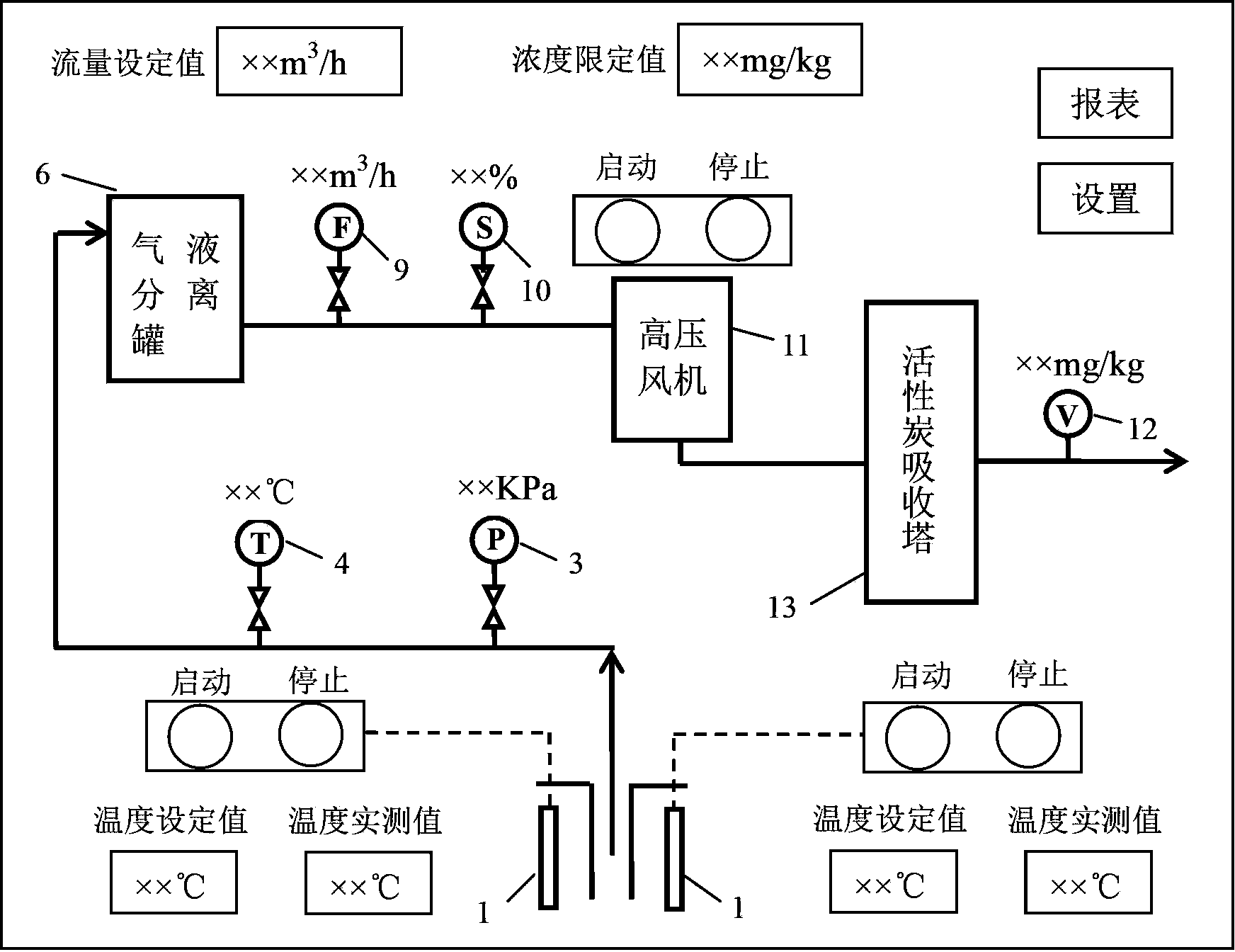

[0022] The 0-5m underground soil heavily polluted by high concentrations of chlorobenzene and dichlorobenzene in a chemical plant site in Shanxi was repaired by using heat-enhanced gas-phase extraction technology. Build a heat-enhanced gas-phase extraction system in the repair site, and use the gas-phase extraction repair without starting the heating electrode. Connect the power supply, turn on the power of the touch control screen, log in to the touch screen operating system, and set the extraction flow to 110m 3 / h, turn on the high-pressure fan to run, and the high-pressure fan drives the gas in the soil to diffuse into the extraction well, and at the same time takes the polluted gas out. The extracted gas first enters the gas-liquid separation tank to realize the separation of gas and liquid. The liquid is discharged from the drain outlet at the bottom of the separation tank after passing the test, and the gas enters the activated carbon absorption tower after passing thro...

Embodiment 2

[0024] Install 18 electrodes per 100 square meters in the same site, with a length of 1 meter and a power of 1.5KW, and start the gas phase extraction repair of the heating electrode. Connect the power supply, turn on the power of the touch control screen, log in to the touch screen operating system, and set the extraction flow to 110m 3 / h, the heat treatment temperature is 130°C. Turn on the high-pressure fan and the heating electrode to run, and the high-pressure fan drives the gas in the soil to spread into the extraction well, and at the same time, the polluted gas is taken out. At the same time as the gas phase extraction, a total of 18 heating electrodes buried in the contaminated site heat the soil. When the temperature of the temperature measurement point in the soil is higher than 130°C, the automatic control cabinet immediately stops the power supply to the heating electrodes, and vice versa. Immediately restore power to the heater electrodes. The extracted gas fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com