Method for controlling speed of hot-rolling thin-gauge loop compensation host machine through variable coefficient

A control method and thin-gauge technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as economic loss, rack scrap, strip deviation, etc., to save downtime and avoid tail flicking , Improve the effect of product surface pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

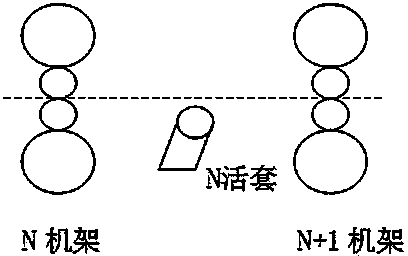

[0007] Such as figure 1 As shown, between each adjacent stand of the finish rolling unit, the strip steel bites the steel looper and the looper is delayed for 1-2 seconds, and then the looper compensation host speed adaptive variable coefficient control is put into operation. Design an exponential function speed compensation variable coefficient adaptive algorithm that meets the production needs, and determine the parameters according to the process parameters of different steel types ( ), by the amount of looper deviation do the independent variable ( ;in : set value of loop amount; : the actual value of the loop amount), to get different adaptive coefficient values . According to the actual equipment control ability, when the amount of looper sets deviates When greater than 0, design variable coefficient adaptive function: ( ).

[0008] The compensation value is according to the formula calculate, in : Set amount deviation mm at the nth moment, :...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com