A kind of puncture leak-proof safety tire for air protection

A safety tire and anti-leakage technology, which is applied to tire parts, transportation and packaging, vehicle parts, etc., can solve the problems of high manufacturing cost, increased weight, and short service life of tires, so as to prolong the normal service life and reduce the Vibration and noise, and the effect of maintaining airtight performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

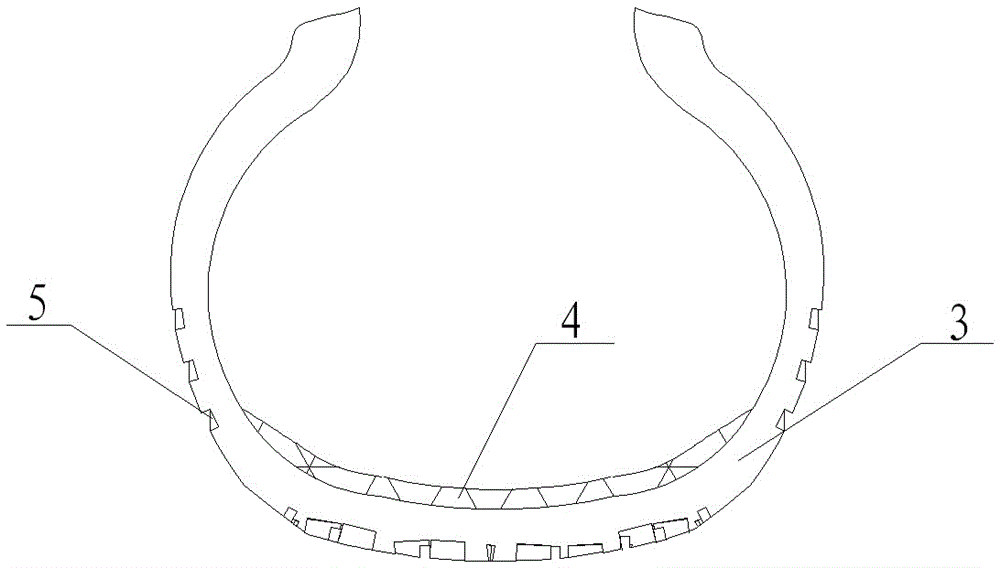

[0044] refer to figure 2 , a kind of anti-leakage safety tire for puncturing, comprising a carcass 3, the inner surface of the carcass 3 is evenly sprayed with a layer of adhesive inner coating 4, and the thickness of the inner coating 4 is 0.5mm; The adhesive is a combination of polyacrylic resin adhesive and polyurethane adhesive. In the present invention, the adhesive inner coating 4 is evenly coated on the inner wall of the tire, the thickness of the coating is uniform, and the thickness of the side part of the tire is consistent with that of the middle part, plus or minus 0.1mm.

[0045] The punctured anti-leakage gas is prepared by the following process:

[0046] (1) dissolving the mixed adhesive of polyacrylic resin adhesive and polyurethane adhesive in acetone with a weight ratio of 1:1.5 to obtain an adhesive solution; the solid content in the adhesive solution is 63%;

[0047] (2) Carry out atomized spraying: Utilize the spraying machine that the adhesive solution...

Embodiment 2

[0060] refer to figure 2 , a kind of anti-leakage safety tire for puncturing, comprising a carcass 3, the inner surface of the carcass 3 is uniformly sprayed with a layer of adhesive inner coating 4, and the thickness of the inner coating 4 is 3.7mm; The adhesive is a combination of polyurethane adhesive, polyamide adhesive and hot melt adhesive. In the present invention, the adhesive inner coating 4 is evenly coated on the inner wall of the tire, the thickness of the coating is uniform, and the thickness of the side part of the tire is consistent with that of the middle part, plus or minus 0.1mm.

[0061] The punctured anti-leakage safety tire is prepared by the following process:

[0062] (1) Dissolving the mixed adhesive of polyurethane adhesive, polyamide adhesive and hot-melt adhesive in the weight ratio of 1:0.8:0.5 in N,N-dimethylformamide to obtain an adhesive solution; the solid content in the adhesive solution is 52%;

[0063] (2) Carry out atomized spraying: Uti...

Embodiment 3

[0076] refer to figure 2 , a kind of anti-leakage safety tire for piercing, comprising a carcass 3, the inner surface of the carcass 3 is evenly sprayed with a layer of adhesive inner coating 4, and the thickness of the inner coating 4 is 4.5mm; The adhesive is a combination of water-based polyurethane adhesive and water-based polyacrylate adhesive. The setting range of the inner coating 4 is the entire tire crown and extends to the first anti-scratch line 5 of the tire in the direction of the shoulder. In the present invention, the adhesive inner coating 4 is evenly coated on the inner wall of the tire, the thickness of the coating is uniform, and the thickness of the side part of the tire is consistent with that of the middle part, plus or minus 0.1mm.

[0077] The punctured anti-leakage safety tire is prepared by the following process:

[0078] (1) Mix water-based polyurethane adhesive and water-based polyacrylate adhesive with a weight ratio of 1:0.6 to obtain a liquid ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap