Piler for small tile package and control method

A technology of small tiles and stackers, which is applied in the stacking, transportation and packaging of objects, can solve the problems of low production efficiency, poor mechanization, and high rework rate, and achieves a wide range of applications, ensuring neatness and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

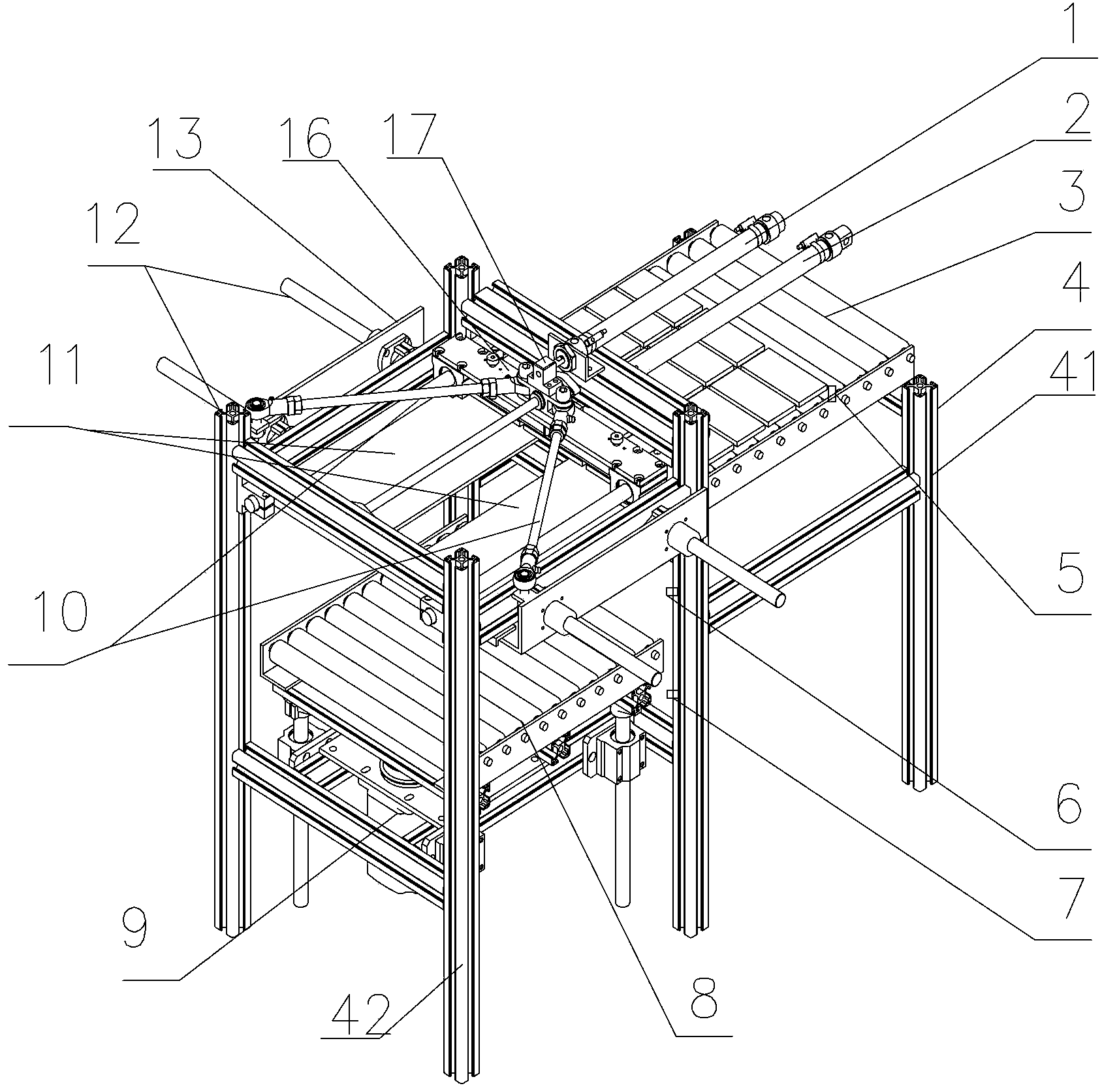

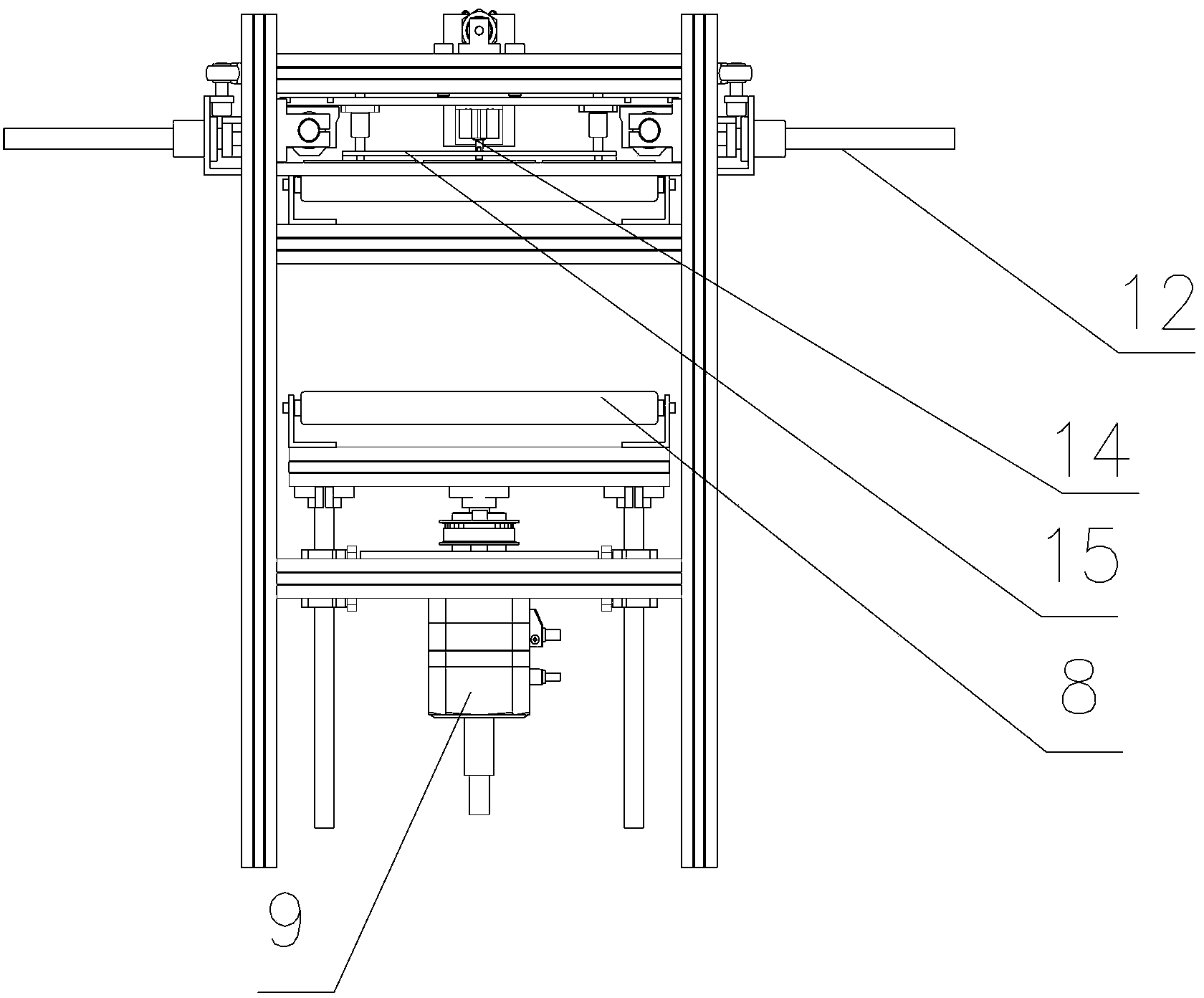

[0031] This embodiment provides a stacking machine for packaging small ceramic tiles. The stacking machine is mainly composed of a base and a lifting platform, wherein the lifting platform adopts a multi-cylinder structure. The feeding cylinder drives the loading push plate to pull the small tiles into the loading position, and the unloading cylinder drives the unloading plate through the connecting rod to realize the stacking and palletizing of small tiles.

[0032] Such as figure 1 , figure 2 As shown, the stacker for packaging small tiles in this embodiment includes a blanking cylinder 1, a loading cylinder 2, a loading transmission drum 3, a frame 4, a loading sensor 5, a safety limit switch 6, and an origin limit switch. Position switch 7, blanking transmission drum 8, stepping motor 9, connecting rod 10, blanking push plate 11, guide rod 12, guide plate 13, pressing cylinder 14, loading push plate 15, loading moving plate 16 and Hinge 17; described frame 4 comprises l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com