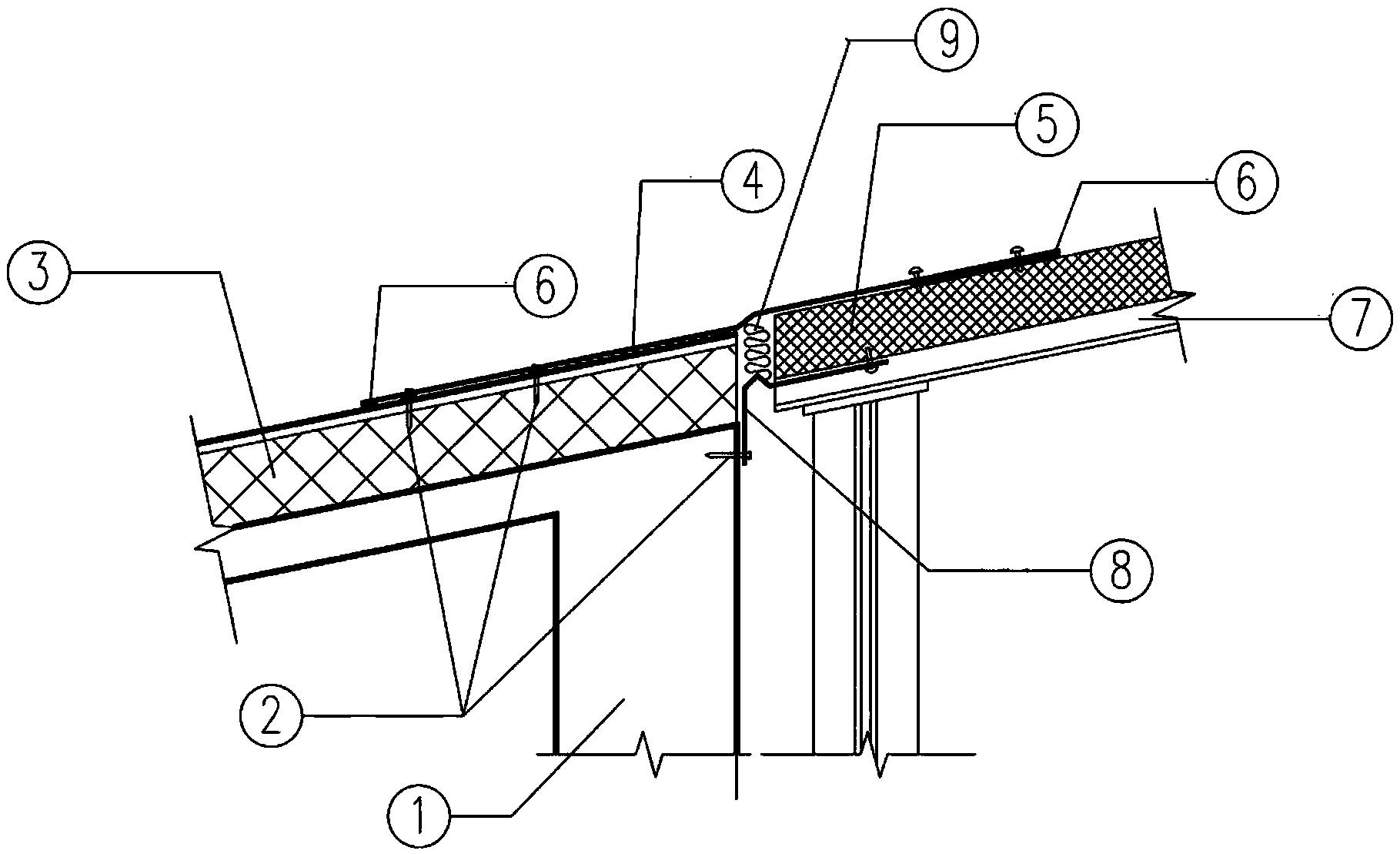

Deformable connection structure of concrete roof and metal plate roof

A concrete and metal plate technology, applied in the direction of building components, bridge parts, bridges, etc., can solve the problems of unable to realize construction, unable to meet the gap width, unable to meet the deformation joint and other problems, and achieve the effect of simple construction and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] When connecting the concrete roof and the metal plate roof, the following steps can be used.

[0018] a. There is a certain gap between the concrete roof and the metal plate roof. The roof keel 7 is aligned with the beam 1 of the concrete roof. First, the iron sheet 8 is installed on the connection between the beam 1 of the concrete roof and the roof keel 7 of the metal plate roof. At the lower end, as a plug, the iron sheet is fixed on the side of the concrete beam close to the deformation joint with steel nails 2, and the iron sheet 8 is fixed on the lower end surface of the roof keel 7 of the metal plate roof with rivets, wherein the iron sheet 8 is in the deformation joint. The length is greater than the length of the deformation joint, that is, the iron sheet 8 has a certain surplus;

[0019] b. Lay the thermal insulation material 3 and the metal sandwich panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com