A thyristor converter valve assembly

A technology of thyristor converter valve and thyristor radiator, which is applied in the direction of electrical components, electric solid devices, semiconductor devices, etc., can solve the problems of increasing the risk of water leakage in the water system, short-circuit accidents of lower-layer electrical components, and difficulty in waterway design. The effect of water leakage risk, guaranteed service life, and reduced design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

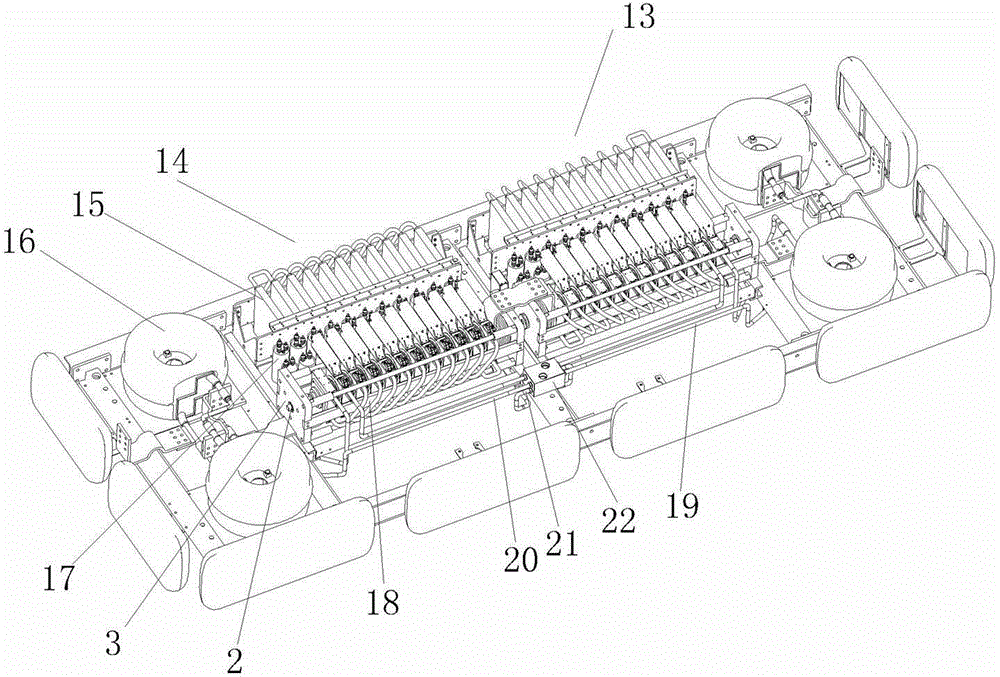

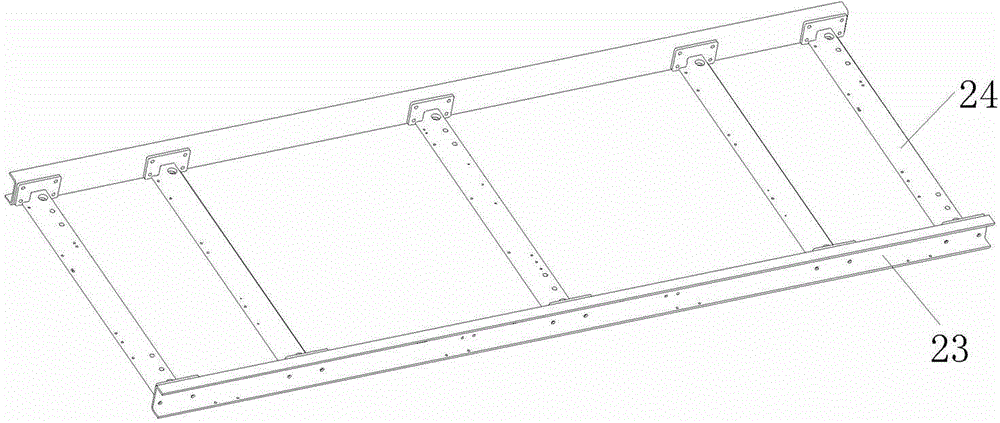

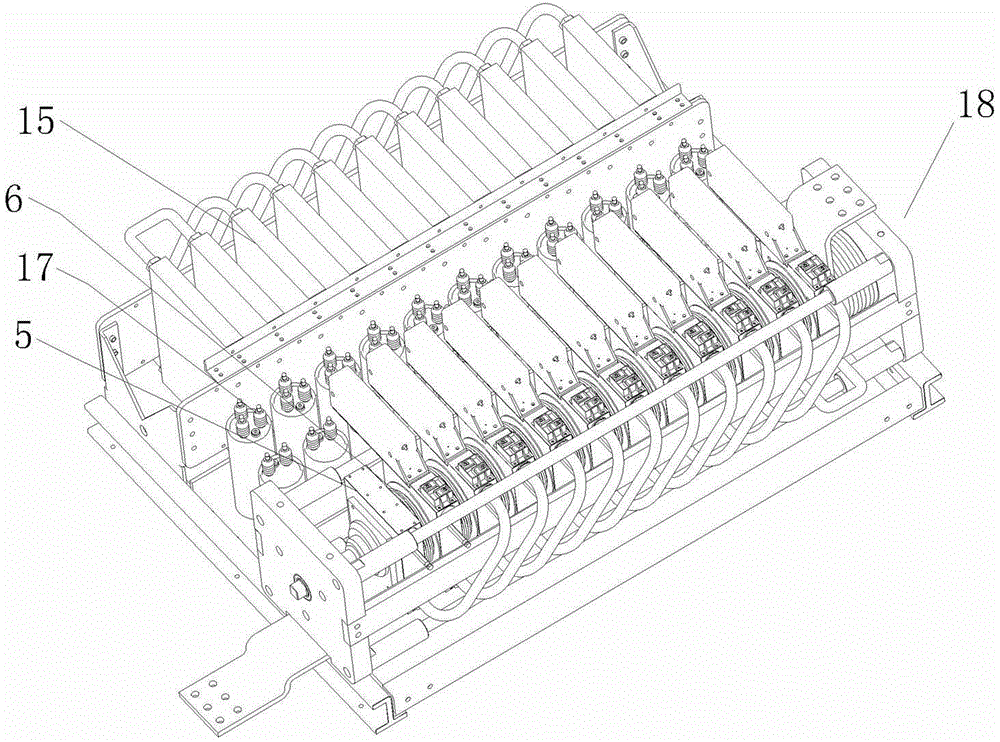

[0024] An embodiment of a thyristor converter valve assembly is Figure 1~7 Shown: including the bracket, the bracket is composed of two U-shaped insulating beams 23 arranged in parallel and a plurality of beams 24 arranged between the two U-shaped insulating beams, and the left valve unit arranged symmetrically on the left and right is arranged on the bracket 14 and the right valve unit 13, the left valve unit includes a reactor assembly 16 and a valve module, the valve module includes a valve section 18, a damping resistance unit and a damping capacitor unit, the damping capacitor unit includes a damping capacitor 17 and an insulating support, and the damping capacitor is arranged vertically upward , to facilitate the heat dissipation of the junction box of the capacitor pillar, and the damping capacitor adopts a combination of long and short structures, which can make the overall structure more compact under the condition of ensuring the electrical distance between the dampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com