Solar greenhouse with high land utilization rate

A technology of solar greenhouse and high utilization rate, which is applied in the field of vegetable cultivation, and can solve the problems of low land utilization rate and not suitable for construction in areas with shallow groundwater levels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] This embodiment is to facilitate the understanding of the present invention without limiting the claims and core content of the present invention in any way.

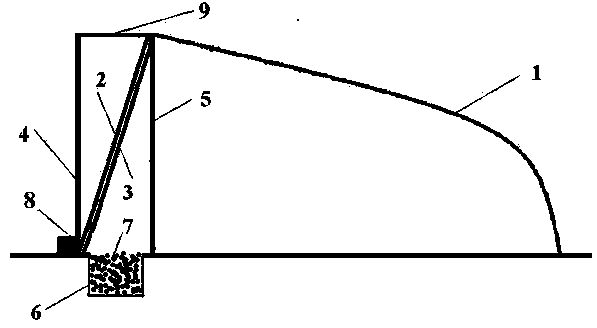

[0029] Examples such as figure 1 As shown, a solar greenhouse with high land utilization rate includes a rear wall, a gable wall, a rear column 4, a front column 5, a front slope 1, a heat storage ditch 6, a top operating platform 9 and a waterproof platform 8.

[0030] The back wall is composed of a support frame, a polystyrene foam board 2 with a thickness of 10-12 cm, and a reflective curtain 3. The polystyrene foam board 2 is fixed on the support frame, and the reflective curtain 3 is fixed on the inner side of the polystyrene foam board 2. The back wall and the ground The included angle is 75°-80°, the polystyrene foam board 2 is sealed and connected to the rear of the front slope 1, the upper end of the reflective curtain 3 is fixed on the top of the front slope 1, and the lower end is provided with a bead....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com