Auxiliary mechanical arm for soft lens operation

A technology of manipulators and soft mirrors, which is applied in the field of medical devices, can solve problems such as vibration, inability to realize precise multi-directional control of flexible devices, and damage to flexible devices, so as to prevent shaking, increase the probability of successful operation, and avoid danger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

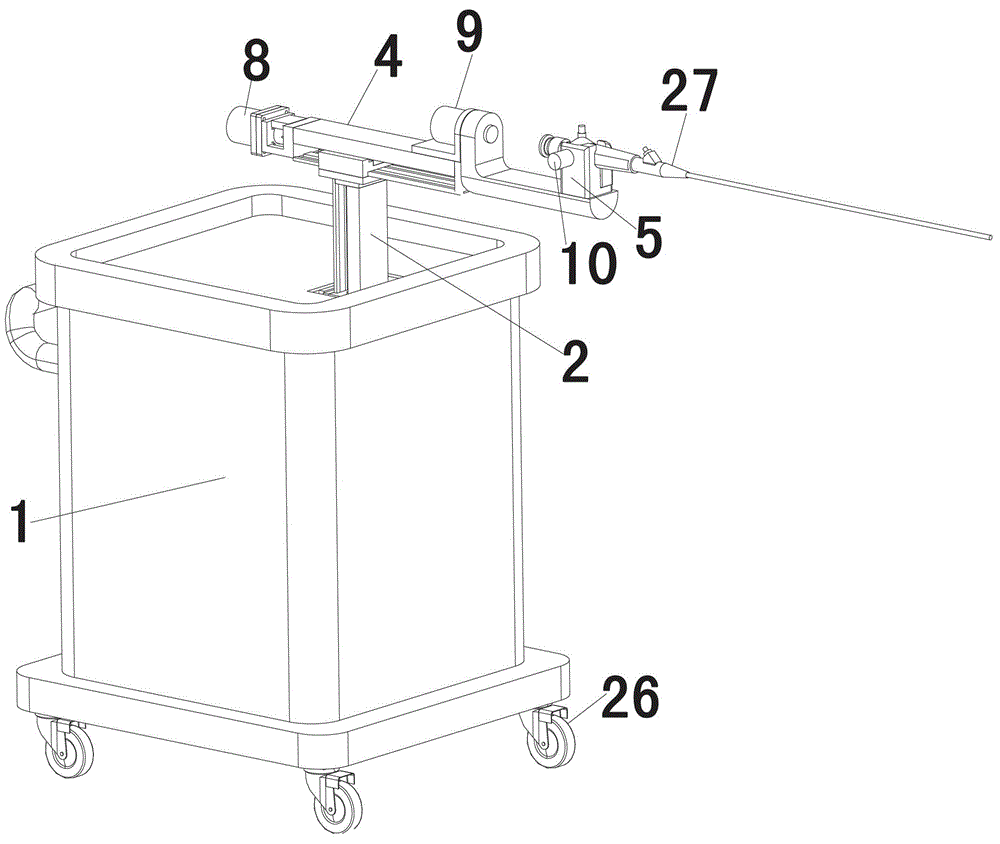

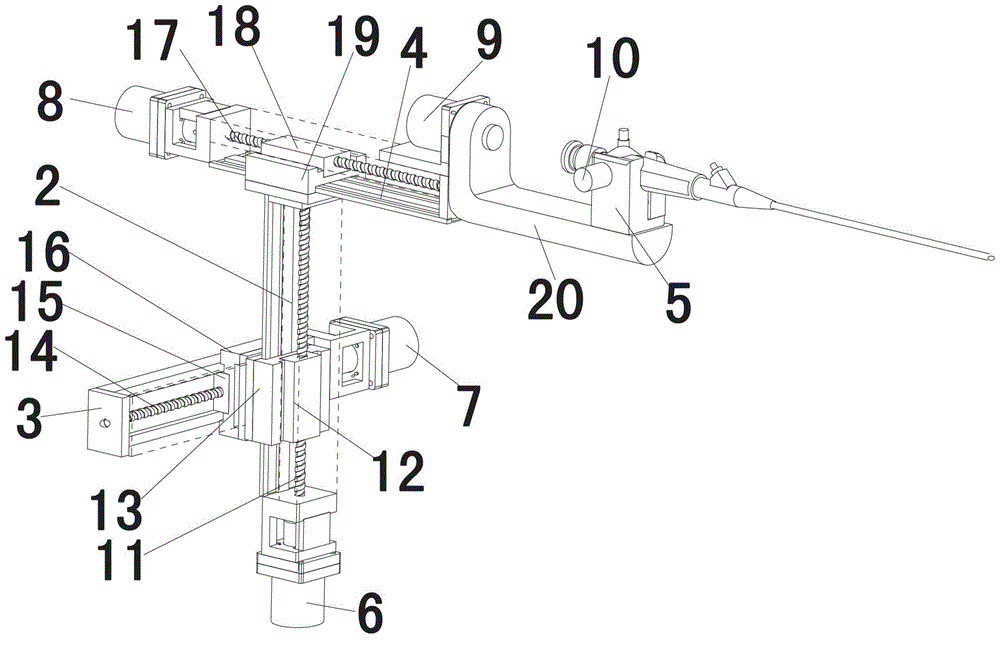

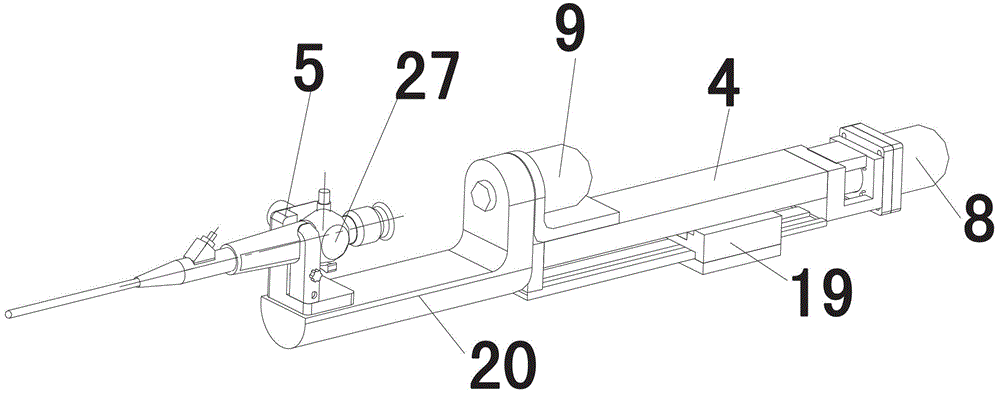

[0049] Such as Figure 1~5 As shown, an auxiliary manipulator for soft mirror surgery includes a base 1, a vertical upper and lower mechanical arm 2, a horizontal left and right mechanical arm 3, a front and rear retractable mechanical arm 4, a soft mirror holder 5, an upper and lower dimension driving motor 6, and a left and right mechanical arm. Dimension drive motor 7, front and rear dimension drive motor 8, rotating shaft dimension drive motor 9 and soft mirror dial dimension drive motor 10; wherein, as figure 2 As shown, the vertical upper and lower mechanical arms 2 are provided with a first lead screw 11 and a first lead screw nut 12, the first lead screw nut 12 is connected with the first slider 13, and the upper and lower dimension driving motor 6 drives the first lead screw 11 to rotate , to drive the first slider 13 to slide, the horizontal left and right mechanical arms 3 are provided with a second lead screw 14 and a second lead screw nut 15, the second lead scre...

Embodiment 2

[0064] The difference between this embodiment and Embodiment 1 is that: the upper and lower dimension drive motors 6, the left and right dimension drive motors 7, the front and rear dimension drive motors 8, the rotating shaft dimension drive motor 9 and the soft mirror dial dimension drive motor 10 are all servo motors. The bottom of the table is equipped with height-adjustable fixed feet. During the specific operation, the flexible scope is first inserted into the urethra and ureter of the prosthesis through the ureteral guide sheath, and sent into the renal pelvis, and then the handle of the flexible scope is manually placed and fixed on the flexible scope holder according to the requirements. Display the whole process of the soft mirror entering the renal collection system on the touch screen (with the function of displaying images), including the renal pelvis, upper calyx, middle calyx, and lower calyx, and observe the renal collection system; click the corresponding funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com