Visual oil-water mixing and stirring device used for laboratory

A technology of oil-water mixing and stirring devices, which is applied in the direction of mixers with rotating stirring devices, mixers, mixing methods, etc., which can solve the problems of poor repeatability, inability to see the state of the experimental medium in the kettle, and not the initial value of the experiment, etc. problem, to achieve the effect of improving experimental efficiency and accuracy, optimizing experimental design scheme, and good oil-water mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

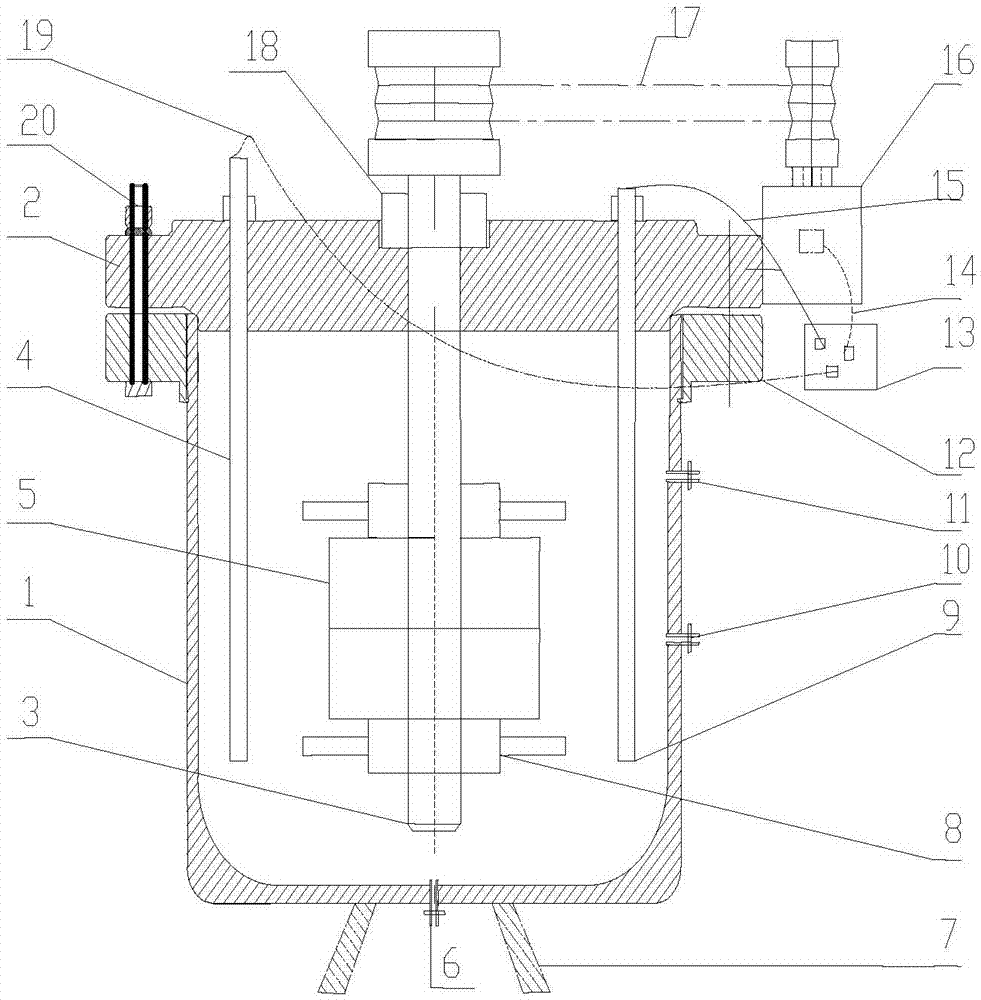

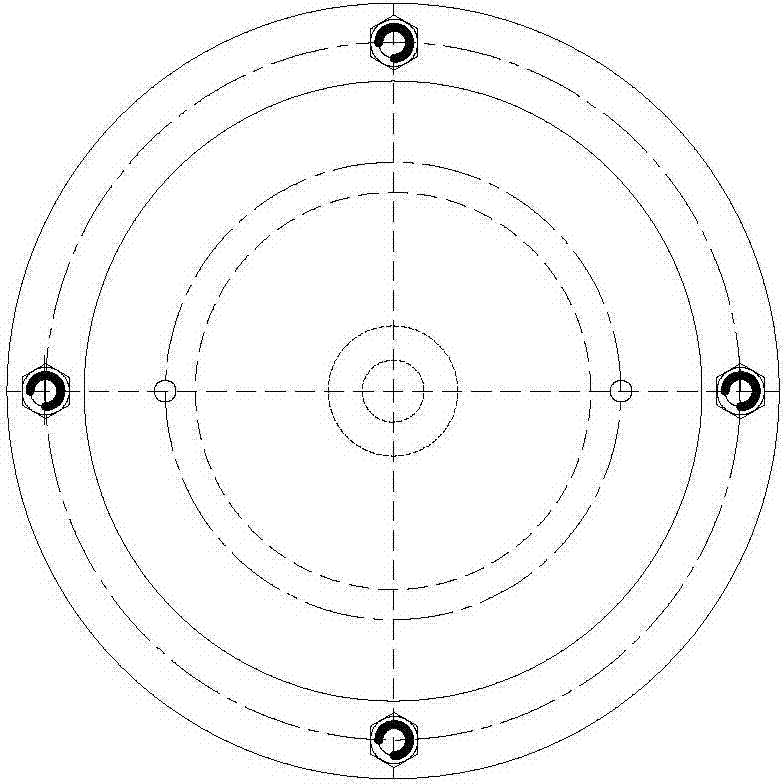

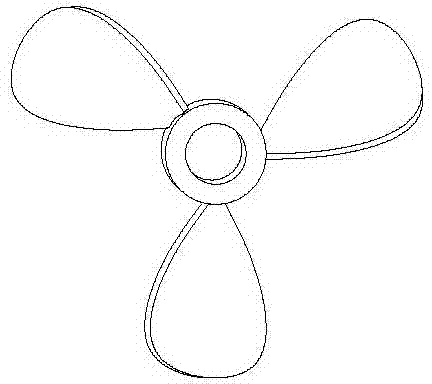

[0025] like figure 1 As shown, the visual oil-water mixing and stirring device used in the laboratory includes a kettle body 1, a kettle cover 2, a rotating shaft 3, a corrosion sample holder 5, a three-blade stirring paddle 8, a temperature and speed control box 13, and a motor 16.

[0026] The kettle body 1 is a cylindrical shell with a closed bottom and an open upper end. The kettle body 1 is equipped with crude oil and water used in the experiment. The kettle body 1 is made of transparent glass, and the mixing state of the crude oil and water in the kettle body can be directly observed; 1 is provided with an upper drain valve 11 and a middle drain valve 10, the bottom of the kettle body 1 is provided with a lower drain valve 6, and the upper drain valve 11, the middle drain valve 10 and the lower drain valve 6 are used for removing The liquid in different parts of the kettle for further determination of liquid composition. A support frame 7 is provided at the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com