Wearable steel ball with reinforced framework

A technology of wear-resistant steel and skeleton, which is applied in the direction of grain processing, etc., can solve the problems of decreased filling rate of effective grinding medium and occupying effective grinding space, etc., and achieves the effects of decreasing filling rate, improving strength and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

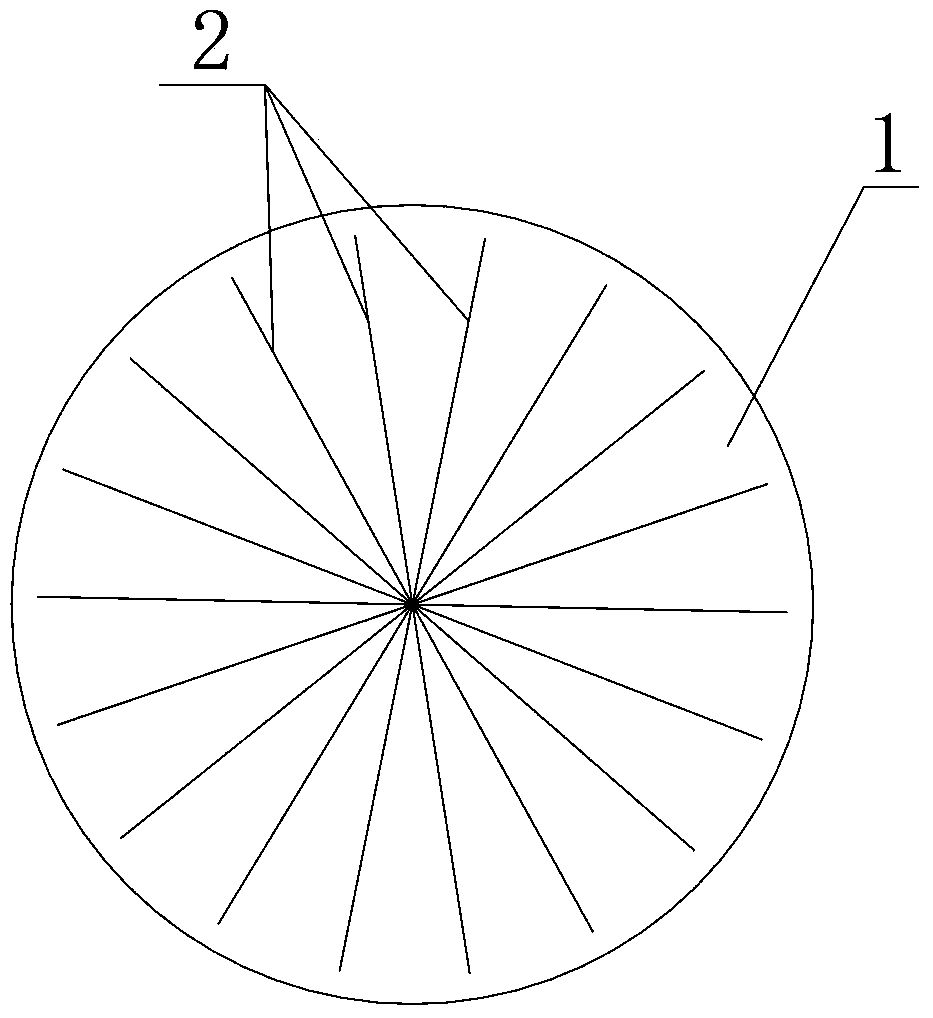

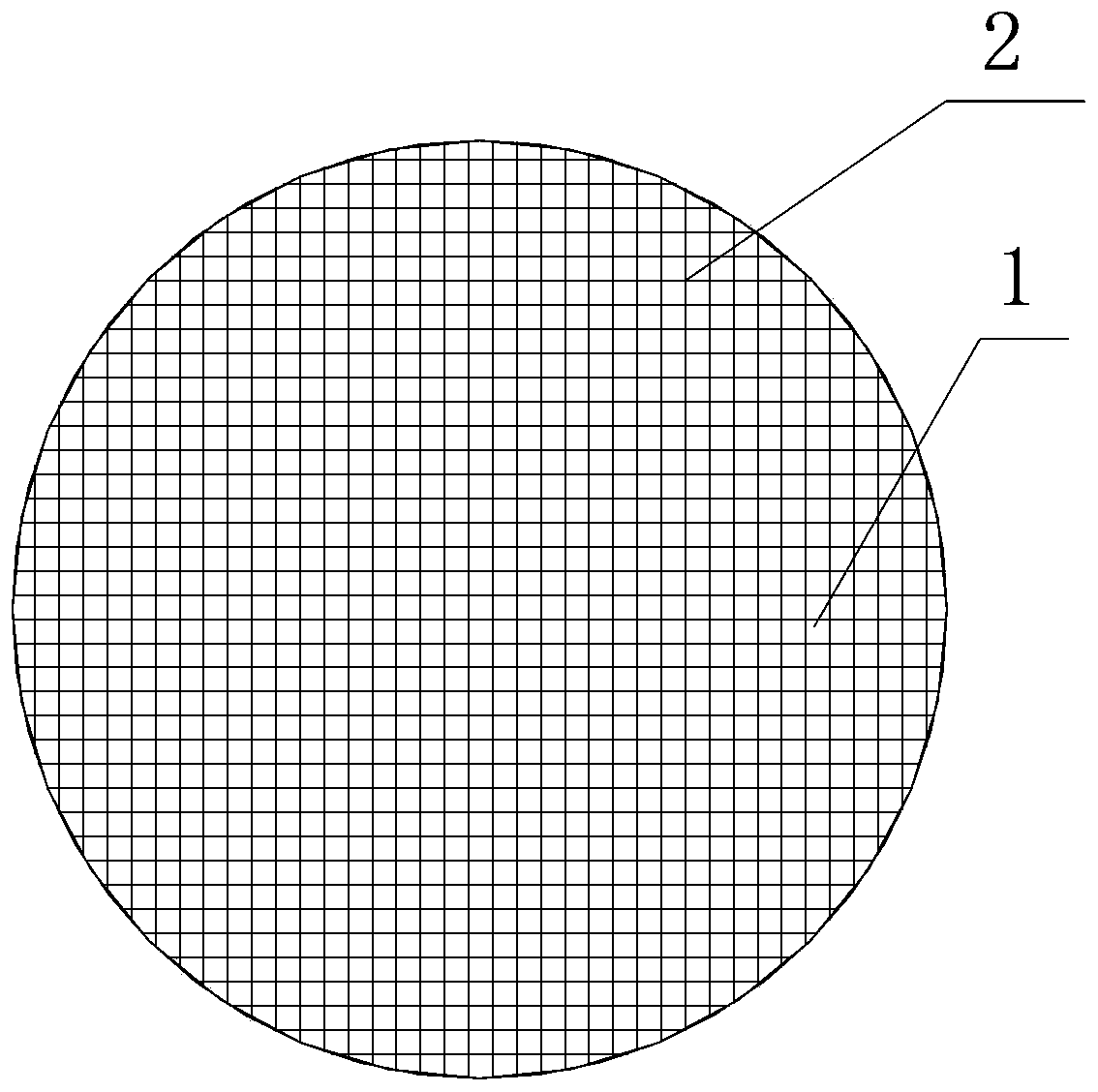

[0013] Such as figure 1 and figure 2 as shown, figure 1 It is a structural schematic diagram of an embodiment of the framework-reinforced wear-resistant steel ball proposed by the present invention; figure 2 It is a structural schematic diagram of another embodiment of the framework-reinforced wear-resistant steel ball proposed by the present invention.

[0014] refer to figure 1 , in one embodiment, a skeleton reinforced wear-resistant steel ball proposed by the present invention includes a skeleton 2 made of high-strength and high-toughness alloy steel and a metal matrix 1 cast on the skeleton 2 by casting ductile iron, and the skeleton 2 is One-piece structure, the skeleton 2 divides the internal space of the steel ball into multiple spaces, the metal matrix 1 fills the interior of the skeleton 2, and forms a package for the skeleton 2; The center is radially arranged inside the steel balls to form the skeleton 2; after the skeleton 2 is made, it is placed in a mold, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com