Flushing assembly of machine tool

A technology of flushing and components, which is applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of reducing work efficiency and cleaning difficulties, and achieves simple structure, ingenious conception, and convenient daily cleaning work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

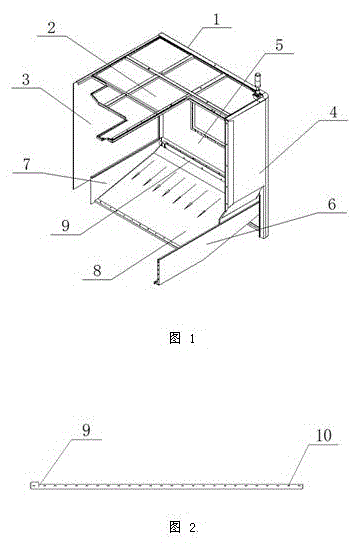

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

[0011] see Figure 1-2 , the specific embodiment is realized by adopting the following technical scheme, which includes a cover 1, the front end of which is surrounded by the top plate 2, the first side plate 3, the second side plate 4, the back plate 5 and the bottom plate 8 is provided with Open square box shape, the top plate 2 is an L-shaped structure composed of five square plates as a whole, the front end extends forward from the L-shaped fixed plate, the middle part of the back plate 5 has a square hole, and the inner part of the bottom plate 8 The sides are obliquely intersected with the back plate 5, and the overall outside is low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com