Hooping machine for outer hoop of all-fiber drum

A technology of paper barrels and hoops, which is applied to cardboard items, etc., can solve the problems of poor control of glue volume, waste of glue, and large force required, and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

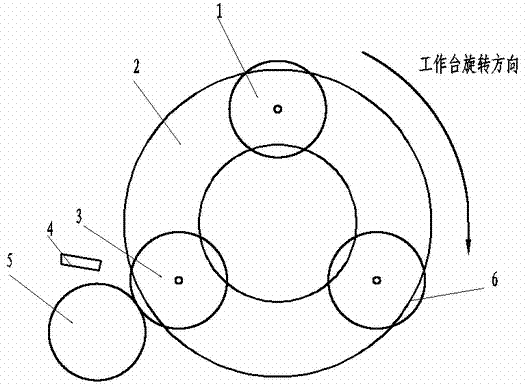

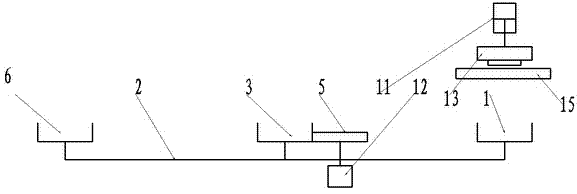

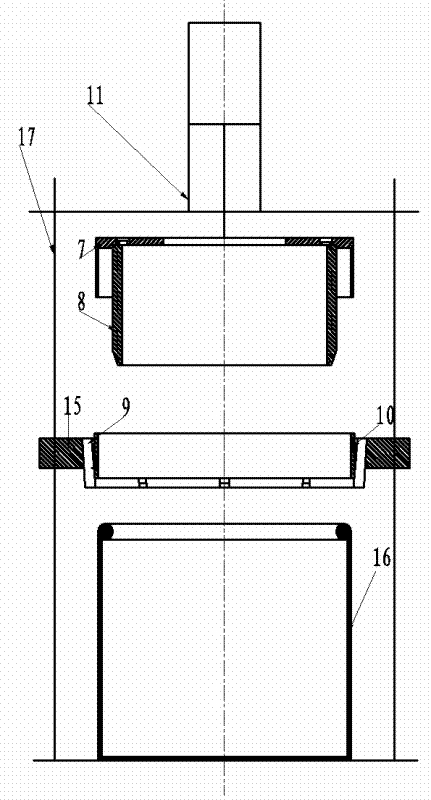

[0029] figure 1 , figure 2 Among them, the upper and lower barrel station 6, the glue spray station 3, and the hoop station 1 are evenly distributed on a rotary table 2 at 120°. Each station on the workbench 2 is provided with a bowl-shaped dish. The rotary table 2 is installed on a rotary support and is driven to rotate by a motor through a reducer. The rotary table 2 is installed on the machine base through the rotary bearing. The bowl-shaped disc on the glue spraying station 3 is driven to rotate through the bowl-shaped disk drive wheel 5 of the glue spraying station by the paper barrel rotating power device 12 . The drum rotating power device 12 includes a motor and a reducer connected to the motor. The output end of the reducer has a rubber wheel or a gear (the bowl-shaped disc drive wheel 5 of the glue spraying station) and the bowl-shaped plate of the glue spraying station for friction transmission or gear transmission. . The paper bucket rotates with the bowl-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com