Stamp managing machine

A technology for managing machines and seals, which is applied in the field of seal management machines, can solve the problems of affecting the work of other parts, affecting the installation of other parts, and the working efficiency of the stamping machine cannot be maximized, so as to ensure the normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The seal management machine of the present invention is equipped with a plurality of seals, and is used in occasions such as government agencies and commercial banks that have relatively high requirements for the management of seals.

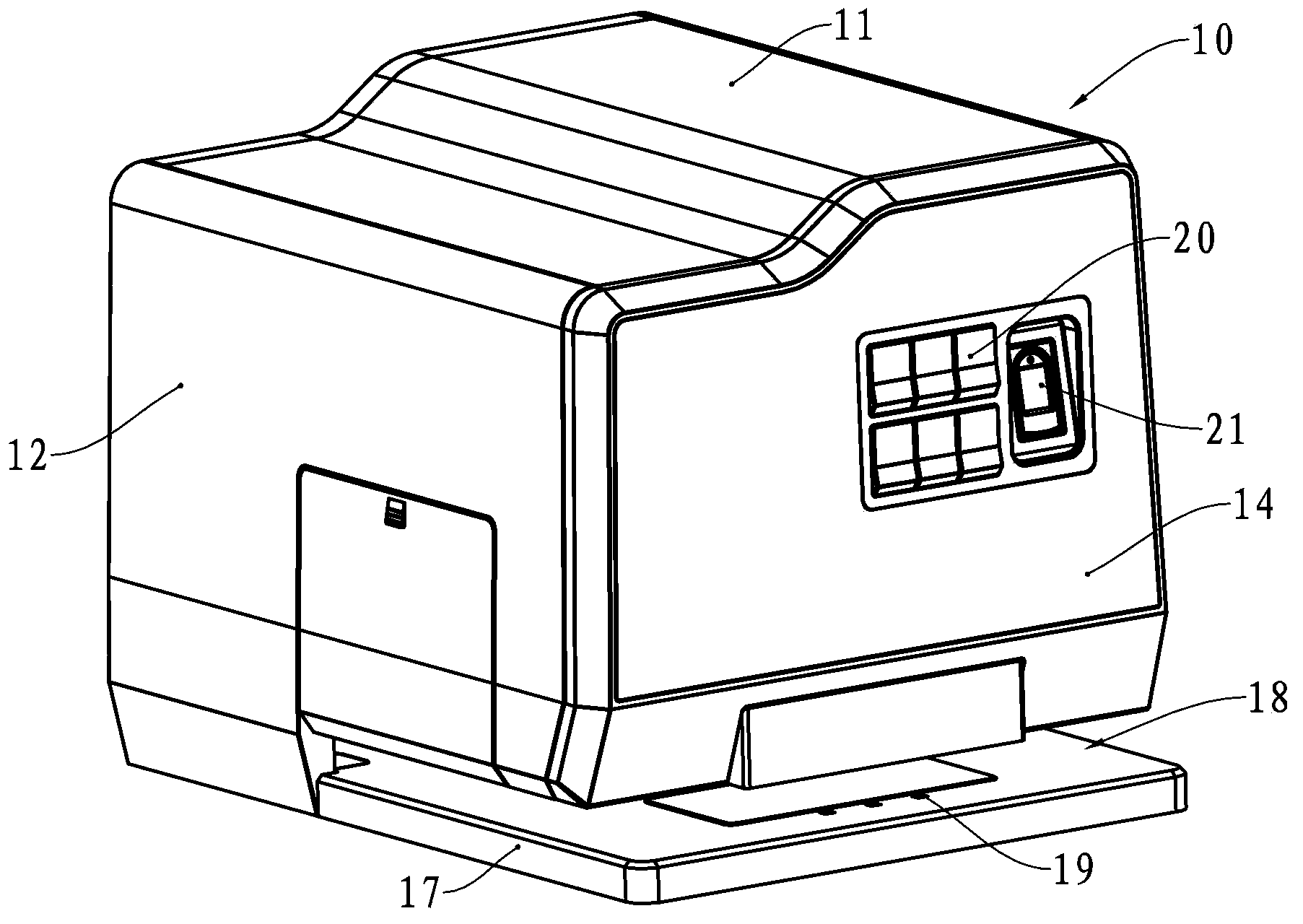

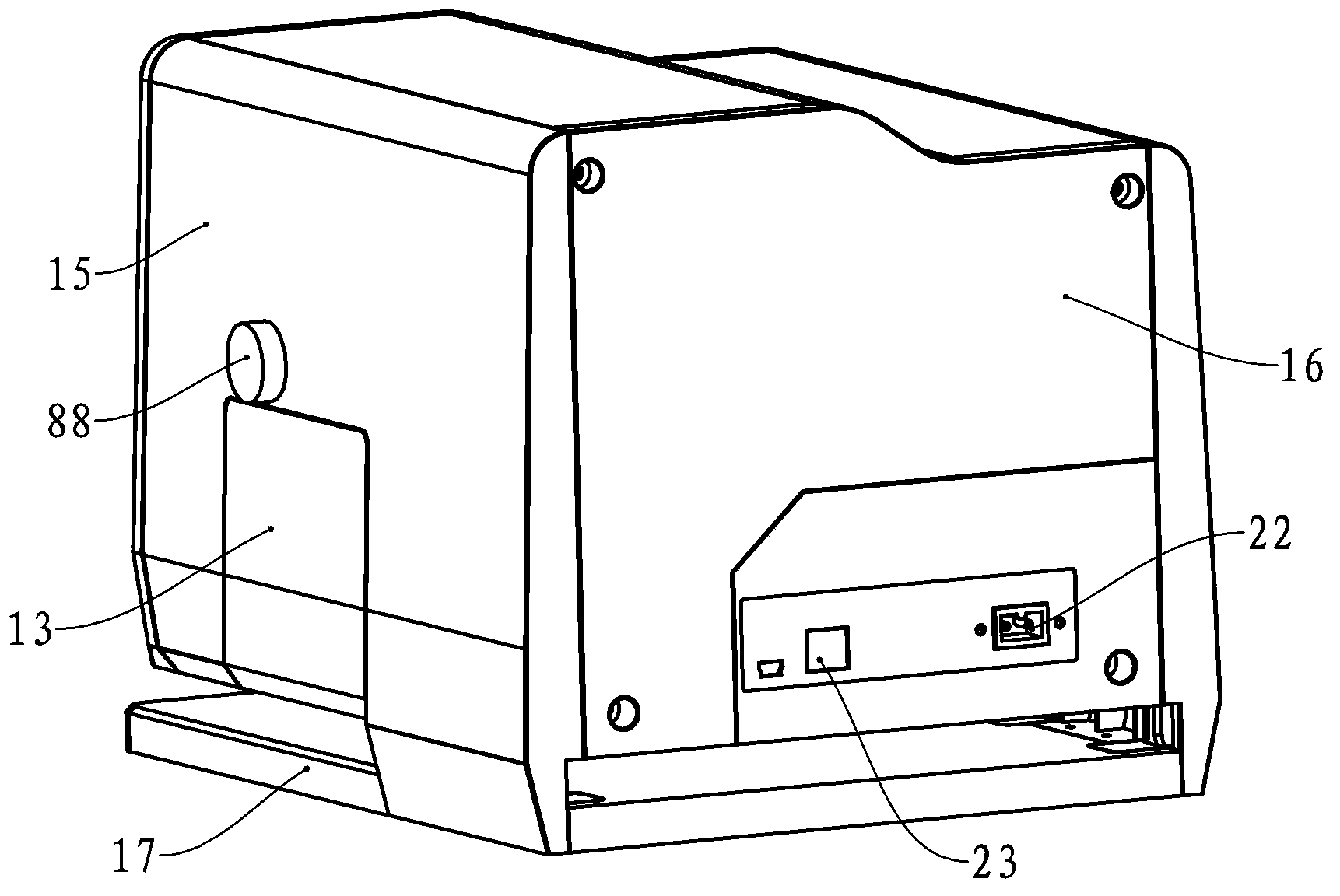

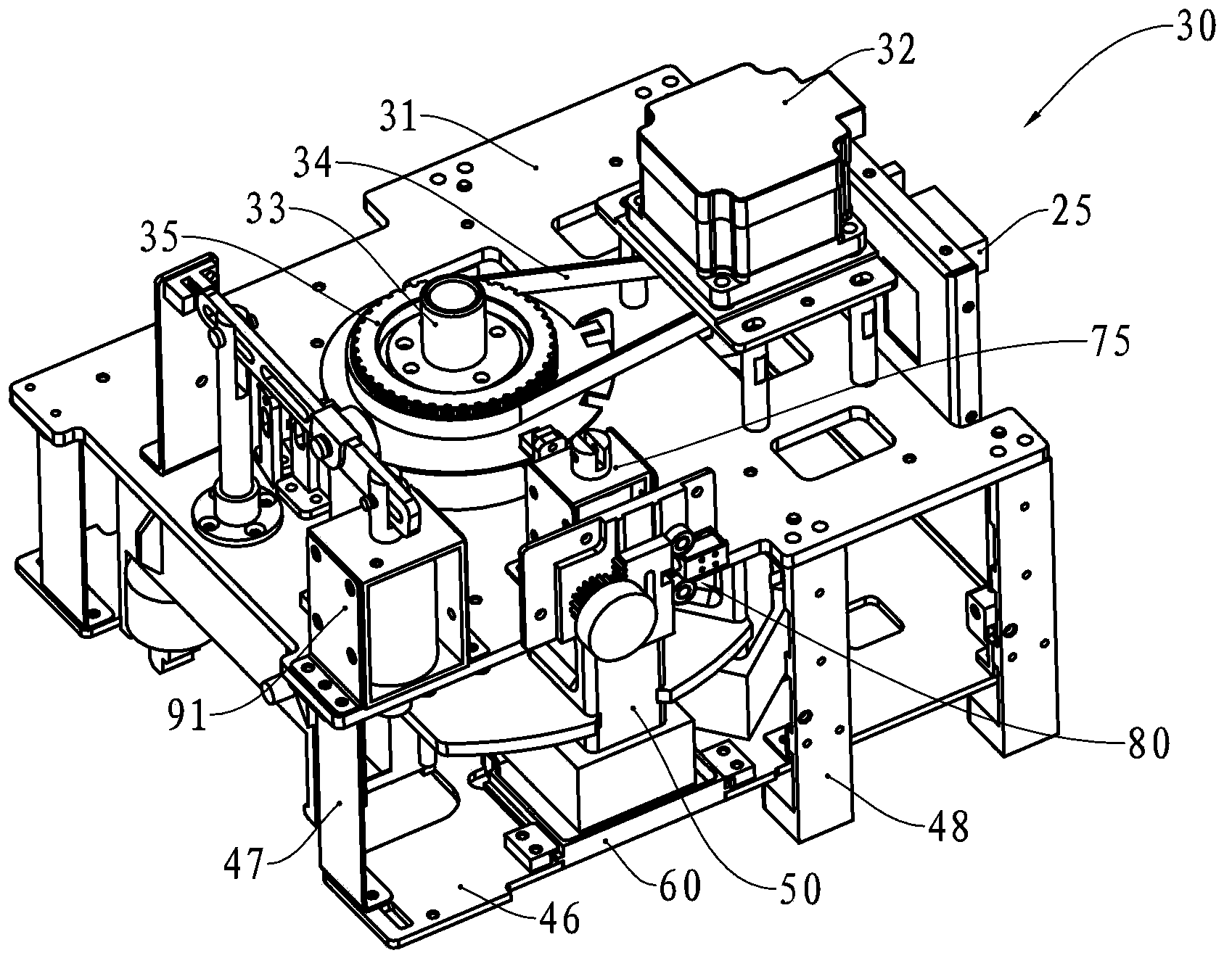

[0037] see figure 1 and figure 2 , the stamp management machine has a housing 10, the housing 10 includes a top wall 11 and four side walls 12, 14, 15, 16 positioned below the top wall 11, the side wall 15 is provided with a small door 13, the small door 13 can Open to facilitate the replacement of the seal installed in the housing 10 . And, also be provided with a knob 88 on the side wall 15, be used to open the lockset 80 that is installed in the side wall 15 ( image 3 Shown), after the lockset 80 is opened, the small door 13 can be opened.

[0038] The lower end of the seal management machine is provided with a base 17, and there is a gap 18 between the bottom walls of the base 17 housing 10. The documents to be stamped can be pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com