Pressure balance type floating body and mounting method thereof

A balanced and floating body technology, applied in the field of ships, can solve the problems of continuous pressure control, real-time measurement, real-time control, and difficult realization, so as to reduce the structural strength requirements, and the attitude adjustment process is simple and controllable. The effect of reducing the force intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

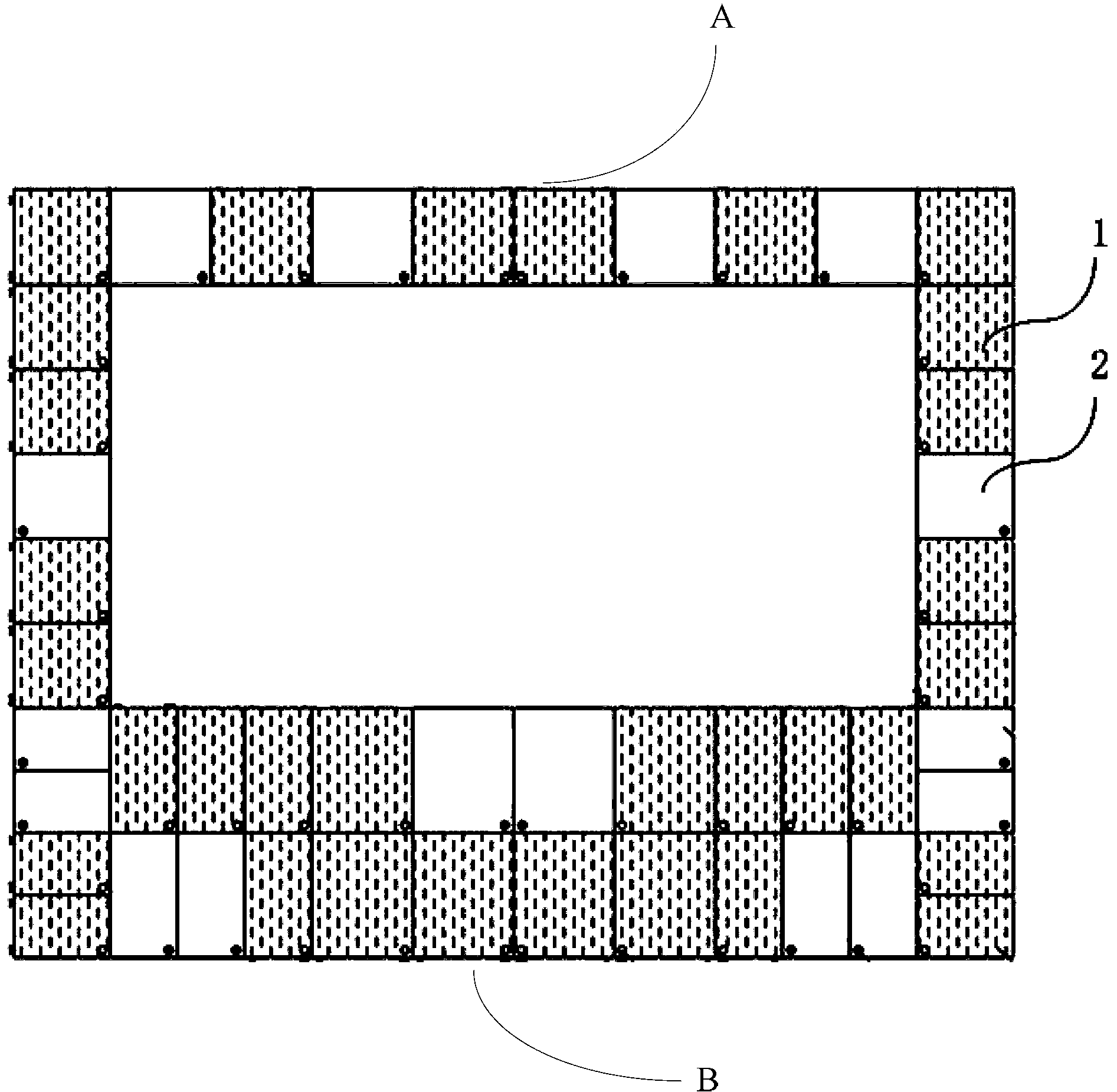

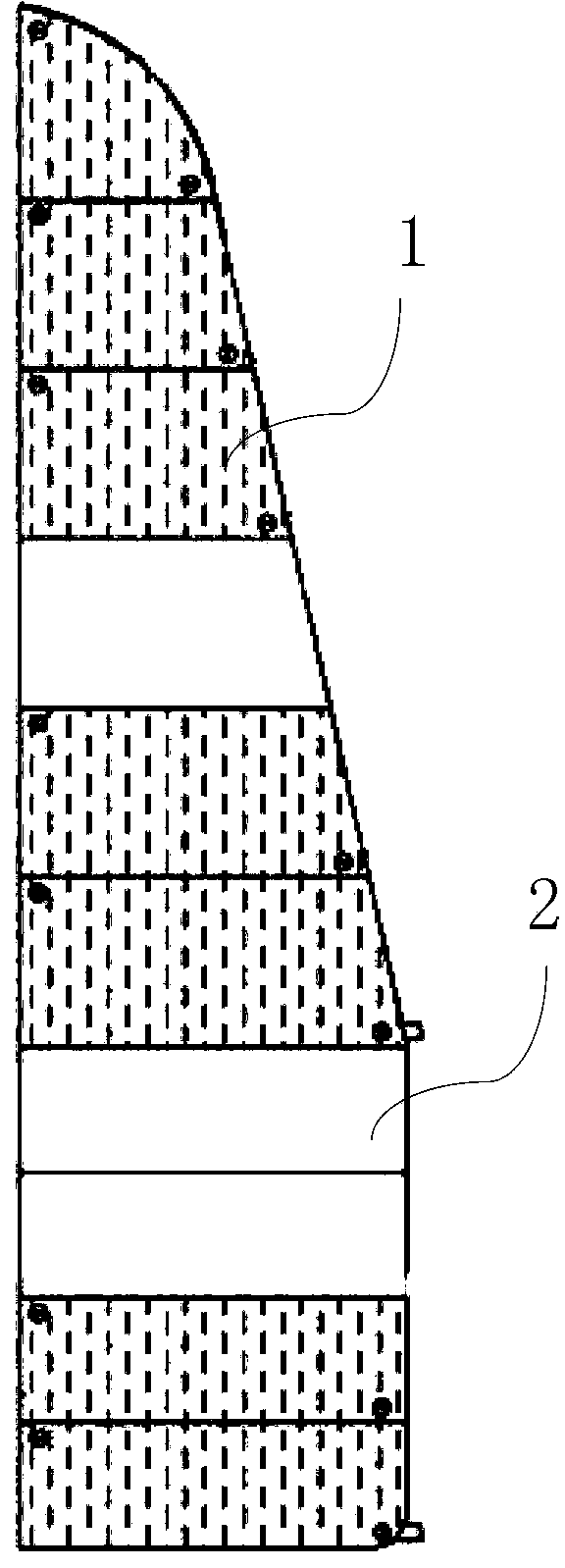

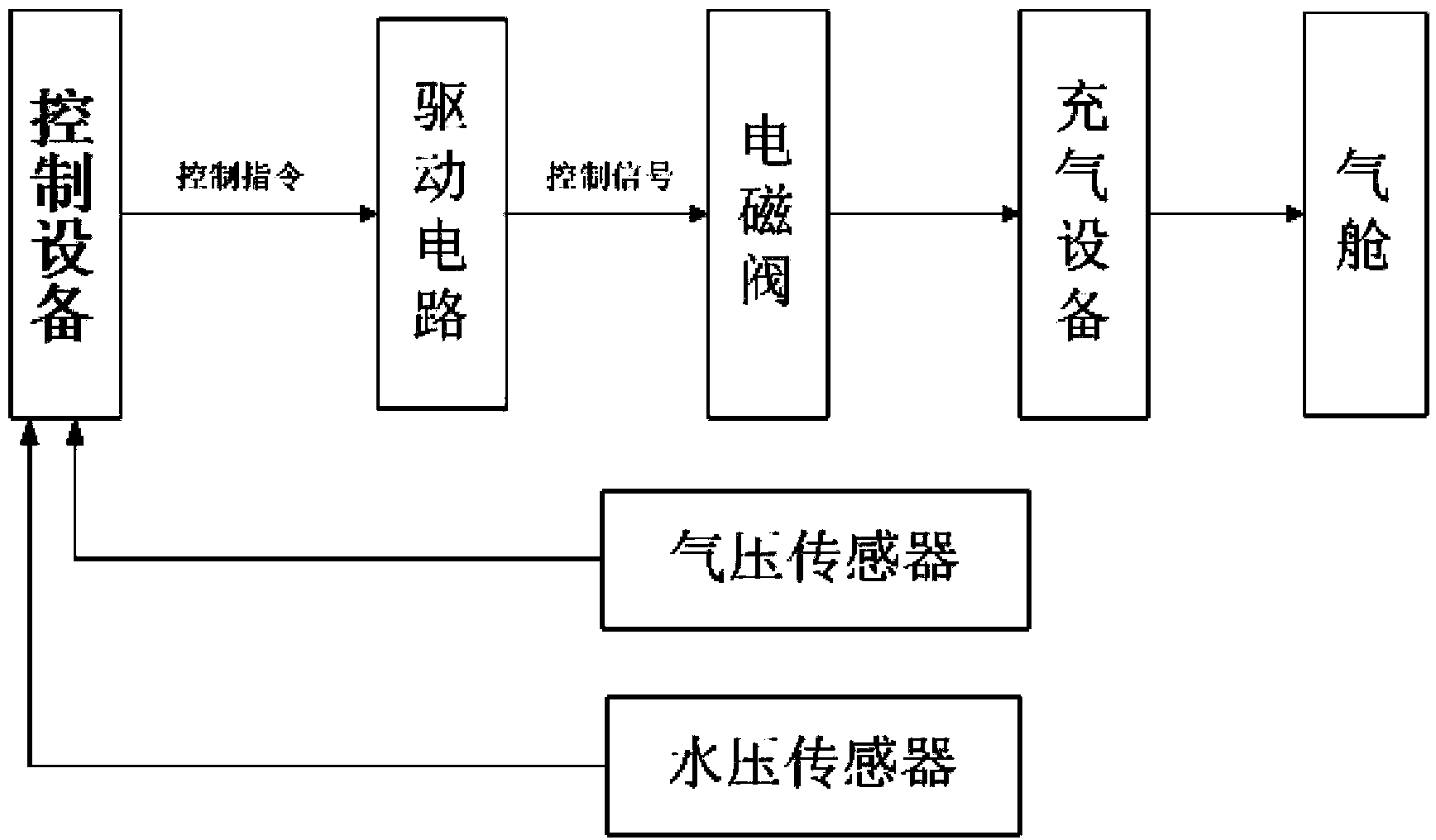

[0023] see Figure 1-Figure 4, the present invention provides a pressure-balanced floating body, comprising a floating body body, an air chamber inflation valve, a water tank water passage system, a water tank ventilation system, a first controller, an attitude monitoring system, and water for controlling the internal air pressure of the floating body body Lower pressure equalization control system. The body of the floating body is divided into at least one water tank 1 and at least one air tank 2. The water tank 1 and the air tank 2 are just two different classifications of internal tanks of the floating body. The materials and connection methods of the two tanks only need good sealing performance. First, the structure of water tank 1 and air tank 2 is introduced. Water tank 1 and air tank 2 are welded by plates of different specifications, specifically: take plates of the same material and thickness, and weld different plates together Multiple compartments are formed, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com