Rotating disc type automatic bagging machine and bagging method

A technology of bagging machine and turntable type, which is applied in the field of turntable automatic bagging machine and bagging, can solve the problems of increasing the maintenance and replacement workload of hidden parts, affecting product production efficiency, and inconvenient installation and maintenance. Reduce packaging time, reduce manufacturing and maintenance costs, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

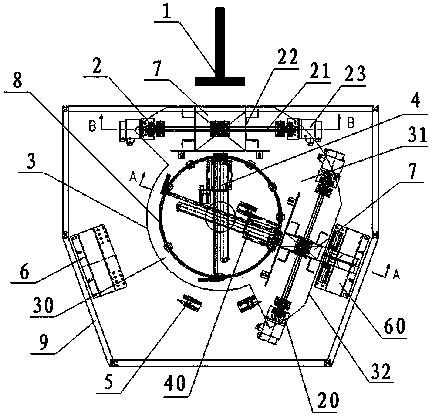

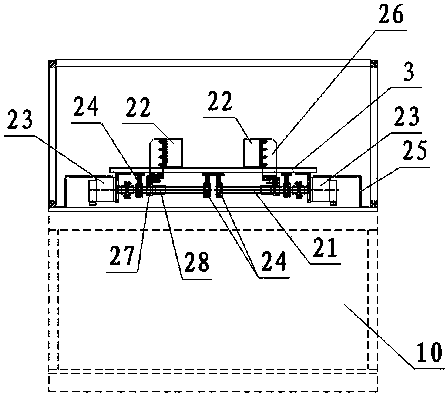

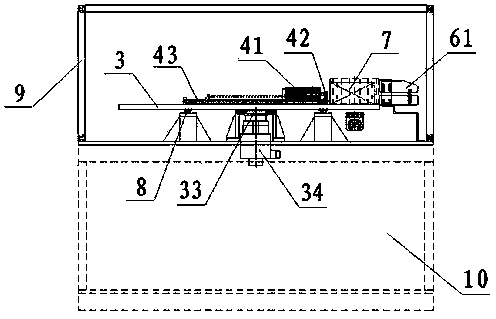

[0016] Embodiment 1: with reference to attached figure 1 , 2 , 3. A rotary table type automatic bagging machine, comprising a frame 10 provided with a safety door 9, a rotary table 3, a pressing mechanism 2, a pushing mechanism 4, and a bagging mechanism 6; the frame 10 is connected to the output port of the stacker 1 docking; the rotary table 3 is installed on the frame 10, and the bottom of the rotary table 3 is provided with a rotating shaft assembly 33 and a motor 34, and the rotation of the rotary table 3 is controlled by the motor 34 and the rotating shaft assembly 33; the pressing of the compressed product 7 Mechanism 2, and the pushing mechanism 4 that pushes the product 7 from the pressing mechanism 2 into the packaging bag are all installed on the rotary table 3; the bagging mechanism 6 is fixed on the outside of the rotary table 3, and the bagging mechanism 6 is provided with a feeding port, that is, a bagging interface 61; the product 7 in the pressing mechanism ...

Embodiment 2

[0020] Embodiment 2: on the basis of embodiment 1, with reference to appended Figure 4 . There are two bagging mechanisms installed on the frame 10, namely the bagging mechanism 6 and the bagging mechanism 60; the bagging mechanism 6 and the bagging mechanism 60 are symmetrically arranged relative to the output port 1 of the stacker, and the three are arranged in a ring , the angle between the three is 120°; there are two pressing mechanisms, i.e. pressing mechanism 2 and pressing mechanism 20; there are also two pushing mechanisms, namely pushing mechanism 4 and pushing mechanism 40 The pressing mechanism 2 and the pushing mechanism 4 are a group, and are set corresponding to the output port 1 of the stacker; the pressing mechanism 20 and the pushing mechanism 40 are a group, and are connected with the bagging interface 61 of the bagging mechanism 60 Corresponding setting; the frame 10 is also equipped with a limit device 5 that controls the rotational position of the rotar...

Embodiment 3

[0021] Embodiment 3: A method of bagging using the rotary disc-type automatic bagging machine in Embodiment 2: using a stacker to push the product 7 from the output port 1 of the stacker into the two pressing blocks of the pressing mechanism 2 between 22; two compression motors 23 on the pressing mechanism 2 start, and drive two pressing blocks 22 to compress the product 7; at the same time, the rotary table 3 rotates to the left under the action of the motor 34, and the pressing mechanism 2, The pushing mechanism 4 corresponding to it all rotates to the bagging mechanism 6, and the product 7 is located at the opening end of the bagging interface 61 in the bagging mechanism 6; at this time, the pressing mechanism 20 and the pushing mechanism 40 are rotated to the stacker At the output port 1, the product 7 enters the pressing mechanism 20 to be compressed; the pushing cylinder 41 of the pushing mechanism 4 is activated, and the pushing block 42 at the top of the push rod is pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com